Wet Wipes Machine Cost- Ultimate Pricing Guide

How much does a wet wipes machine cost?

-Ultimate Pricing Guide.

As you consider purchasing a wet wipes machine from us, the very first question you would ask probably is: how much does a wet wipes machine cost?

This pricing guide helps to give you an idea about the initial budget and the ownership costs associated with each type of wet wipes machines.

Buying a wet wipes machine is a lot like buying a car.

With so many options available, price ranges can vary drastically.

In general, a wet wipes machine can cost $17,500–$500,000 upfront depending on a wide range of factors including Technology, Capacity Speed, Functions & Features, Make of Components, Electronic System, Program, Automation level and its Workmanship (machine finishes).

Keep in mind that there are two things to consider when evaluating the cost of a wet wipes machine:

-

The initial purchase price of the wet wipes machine

What you pay upfront when you buy it. This includes the wet wipes machine itself plus all the accessories.

-

The lifetime cost of ownership associated with the wet wipes machine

The Total Cost of Ownership on a wet wipes machine includes everything you spend after the purchase including any replacements, repairs, operational costs and maintenance.

In general, initial purchase costs, or what we call it start-up costs and lifetime costs of ownership (operating costs) constitute Total Cost of Ownership. (TCO).

First, let’s take a look at the initial cost of wet wipes machines and get an idea of how much to budget for each type.

Initial wet wipes machines cost

The average initial cost for a wet wipes machine can range from $17,500 up to $500,000.

What affects the initial price of a wet wipes machine?

Major factors affecting the upfront price of a wet wipes machine including:

- Types of wet wipes machines (Single sachet wet wipes machine/ Cross-fold Wet Wipes Machine /Flow pack Wet Wipes Machine /Canister Wet Wipes Machine)

- Features & Functions

- Capacity speed

- Make of components

- Program

- Electronic system

- Design ( Any room for future upgrades?)

- Automation levels

- Output product Quality

- Workmanship

- Add-ons & accessories

- Installation & commissioning

Let’s take a look at each factor.

Types of wet wipes machines

Generally speaking, there is no one-size-fits-all wet wipes machines.

You can not expect to buy a wet wipes machine that can make all types of wet wipes at different sizes/ specifications.

Based on this fact, it is easy to understand why we would in the first place direct you to look at all the types of wet wipes machine available on the market when you come to us with the query “How much does a wet wipes machine cost?”.

Wet Wipes can be divided into three categories by its applications:

Personal care wipes:

include baby wipes, hand sanitizing wipes, makeup removal wipes, facial cleaning wipes, body cleansing wipes , feminine hygiene wipes, medical wipes, flushable toilet wipes.

Household wipes include wipes for general purpose home care- surface disinfecting wipes, floor cleaning wipes, kitchen cleaning wipes, toilet cleaning wipes, automotive car cleaning, lens cleaning wipes, and shoe polishing wipes.

Commercial/ industrial wipes include general purpose wipes, speciality wipes(Degreasing / Machinery cleaning wipes), wipes for food service and healthcare sector.

However, if you come to a wet wipes machine manufacturer with a request for machines intended for a specific application, you probably will get nowhere.

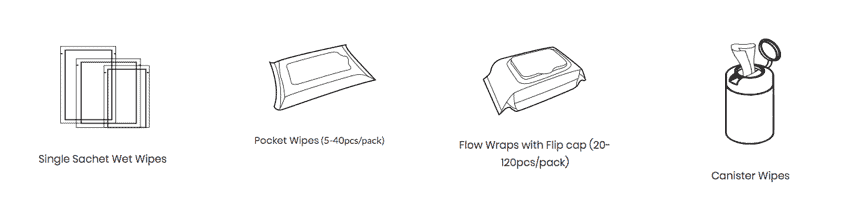

Wet wipes machines are commonly categorized by its work flow into 4 types:

(1) Single Sachet Wet Wipes Machine

On average, the cost of a single sachet wet wipes machine that converts raw material (spunlace non-woven fabric) rolls into a sheet of moist towel in a well packed sachet could come anywhere between $17,500 and $35,500. (These price ranges do not include shipping, installation, etc.)

Click to check Droid’s Model to understand single sachet wet wipes machine.

(2) Cross Fold Wet Wipes Machine (5-40Pcs/Pack)

Cross fold wet wipes machine refers to the machine that is suitable to produce pocket-sized wet wipes in a pack of 5-40counts. (E.g. makeup removal wipes, cosmetic wipes, face hand sanitizing wipes.)

The pricing of such machine varies drastically from supplier to supplier as there are big differences in each manufacturer’s design and technology.

For example: a fully automated cross fold wet wipes production line could cost up to $500,000 ~$650,000 from an Italian manufacturer.

On the contrary, an economic model from a Chinese supplier could come typically at $38,000 ~$70,000. (Yes, that is a tenfold difference in the price tag.)

(Note that we are talking about a fully automated line that consists of wet wipes converting machine and a flow wraps packaging machine).

If you are searching for high performance cross fold machines made by Top ranking Chinese manufacturers, you will get an estimate pricing range between $125,000 and $180,000, depending on capacity, options and accessories.

Click to check Droid’s Model to get an idea of high performance crossfold wet wipes machine.

It’s also not surprising to find many small vendors in China who make an extremely simple cross fold wet wipes converting machine (without packaging system; manual packing is required) that costs generally $14,800 ~ $17,700. Machines that fall into this price range might be a good option for startups who are tight in initial budget and are keen to set up a small scale workshop.

(3) Flow Pack Wet Wipes Machine (20-120Pcs/Pack)

Flow Pack Wet Wipes Machine refers to the machine that is designed to produce big pouch wet wipes in a pack of 20-120 counts. (E.g. Baby wipe; disinfectant wipes; kitchen cleaning towel)

In general, the cost of a flow pack wet wipes machine varies from economic models to high performance models.

An entry-level automated production line that is fitted with such basic functions as tissue folding, slitting, wetting, packaging system could cost only $48,000~$80,000.

If you aim for a higher quality flow pack wet wipes machine that cuts heavy reliance on manpower; is designed in compliance with GMP standard at minimum cost-to-use, the price could range from $125,000~$550,000.

Click to check Droid’s Model to get an idea of high performance flow pack wet wipes machines.

- UT-BL10(12); UT-BM16(20);UT-BH40

- Machine running vide0

(4) Canister Wipes Machine

If you are not aware of the market of canister wipes machine, you probably will be shocked at how expensive a full automated canister wipes production line could be. (Automation here refers to the complete production process exclusive of human intervention). A cost of a mature European line at $1,000,000 could easily scare most buyers away.

However, more affordable semi-automated options are there with price range coming anywhere between $15,500~$70,000.

The fact is, 90% of canister wipes around the globe are made on such machines with human interventions involved that require supporting facilities like liquid filling & top sealing machine, labeling machine and shrink wrapping machine.

Click to check Droid’s Model to get an idea of canister wet wipes machines.

Wet Wipes Lid Applicator(capping machine)

Wet wipes lid applicator is an independent equipment that can be connected to the primary wet wipes packaging machine to achieve plastic lid pick-and-place on wet wipes pouch.

Two major types of Robotic wet wipes lid applicator (capping machine) on the market:

- Cartesian (Linear) robotic wet wipes lid applicator (Mould-based)

It’s pretty common to see such wet wipes capping machine that adopts Cartesian robot.

Advantage of it might be the cost.

On the other hand, such lid applicator is priced at $26,000~$33,000.

However, its disadvantage is also hard to overlook:

- Applicable cap dimensions are quite limited and can only be adjusted by changing mould;

- Accuracy is less satisfying: Linear robot performs linear movement only (up-down, in-out, back- forth); If the moving wipes are not in a linear movement, the robot is not able to rectify to align with a non-linear movement of wipes.

2. Spider robotic (4 Axis) wet wipes lid applicator

Spider robot is also widely adopted in the application of wet wipes capping system.

A good spider robotic wet wipes lid applicator is costing around $48,000~$72,000, depending on the brand of robot arm, motion control system and gluing system.

Related Article:

A buying guide for wet wipes lid applicator (capping machine)

Structure

A typical automated wet wipes production line is composite of three stand-alone systems that can be connected together:

- Wet Wipes Converting machine

- Wet Wipes Packaging machine

- Wet Wipes Lid Applicator

Typical structure of a Wet Wipes Converting machine:

(1) Nonwoven loading stations

(2) tissue folding unit

(3) On-line liquid supply unit (wetting system)

(4) Tissue cutting unit

(5) Tissue stacking unit

You have the option to upgrade from basic structure to a more advanced one that is fitted with automatic non-woven splice unit; web guiding unit, automatic metal joints rejection unit; vision detecting unit etc, and those upgrades will factor into your initial purchase price of a wet wipes concerting machine.

-

Typical Structure of a Wet Wipes Packaging machine:

(1)in-feed conveying unit

(2)labeling unit

(3)film wrapping unit

(4) die-cutting unit

(5) bag former

(6) heating & back-sealing unit

(7) cutting unit

(8) air venting unit

(9) end sealing unit

Options for upgrades:

Automatic film splice unit; Web guiding unit; Coding unit; Vision detecting unit etc, and those upgrades will make differences on your wet wipes packaging machine upfront price.

-

Typical Structure of a Wet Wipes Lid applicator:

(1) labeling unit

(2)Vision system unit

(3) robot arm for pick-and-place

(4) gluing unit

Sine wet wipes converting machine, wet wipes packaging machine and wet wipes lid applicator can all be called “wet wipes machine” individually, typical structure of a wet wipes production line can vary greatly from supplier to supplier, so ask specifically what it includes.

Note that a production line that combines a wet wipes converting machine, a wet wipes packaging machine and a wet wipe lid applicator comes at a higher price range than any of these three equipment that individually can all be called “a wet wipes machine”.

Features & Functions

Features and functions factor heavily into your initial budget of buying a wet wipes machine.

Features bring benefits and account for the ultimate performance.

- A wet wipes machine fitting with an automatic non-woven splicing system that allows for non-stop production won’t cost the same as the ones without this feature.

- A wet wipes machine that has clean in place (CIP) function to clean all the pipes online and avoid any cross-contamination between each change-over.

- A wet wipes packaging machine that comes with servo-driven reciprocating sealing cutter design runs at higher cost than a rotary type.

Capacity Speed

Capacity is probably the most eye-catching parameter that most wet wipes machine buyers will look at when they receive a quotation.

A wet wipes machine that runs at higher speed is sure to cost more.

Side note:

Here are the typical speed levels for each types of wet wipes machine from Chinese vendors:

Cross-fold wet wipes machine (5-40pcs/pack)

- 200-400pcs/min (Smallest scale)

- 400-600pcs/min

- 800-1000pcs/min

- 1400-1500pcs/min (Advanced)

Flow pack wet wipes machine (20-120pcs/pack)

- 1200-1600pcs/min (Smallest scale)

- 1600-3200pcs/min

- 4000-4800pcs/min

- 5600-6400pcs/min

- 7200-9000pcs/min

- 9000-9600pcs/min (Premium)

- 9600-12000pcs/min(Advanced)

Make of components

We all know that materials and brand of components make differences in the wet wipes machine cost.

- A water pipe made of stainless steel does not cost the same as PVC made pipes.

- A cutter blade made of pure tungsten also differs from the ones made of mixed tool metal.

- You pay more for Electronic components made from Siemens than a less well recognized brand.

- Some wet wipes machine manufacturers apply sus304L or sus316L on the parts in contact with product while some could not even point out which grade of stainless steel is used.

Be critical if you notice a big price gap between each offer of a wet wipes machine.

Program

What makes for a good quality wet wipes machine?

I believe PLC Program is one of the silver bullets.

What makes each wet wipes machine manufacturer different lies mostly in their program system.

A good program aligns well with its mechanical motions, reduce scraps and ensure each function runs stably and precisely as it claims to be.

It is not easy to make a justified judgment on the value of an embedded program and its related costs for most outsiders though, just keep in mind that program factors a lot into the pricing of a wet wipes machine.

Electronic System

The biggest influences on the initial budget of buying a wet wipes machine:

- Make of electronic components

Electronic components (e.g. PLC/ Servos) made from Siemens/Mitsubishi values more than a less well-recognized brand.

- Control system

Is the wet wipes machine controlled by CPU/PLC system?

- Servo Motor vs. Stepper Motor

Servo motors are the better choice for applications that require precise and accurate positioning, high speeds while stepper motors provide a simpler, more cost-effective solution. In general, a more advanced wet wipes machine would cost more with the application of branded servo motors.

Design ( Any room for future upgrades?)

The design of a wet wipes machine says much about its advancement.

Advanced wet wipes machines adopt modular design that allows for future upgrades.

Traditionally, the only way to double your current production capacity is to buy a totally new production line. With the modular design, all you need is to pay for one more block that can be added up to the production line.

Initial costs of the line might be less attractive but Thousands of dollars saved in the long run!

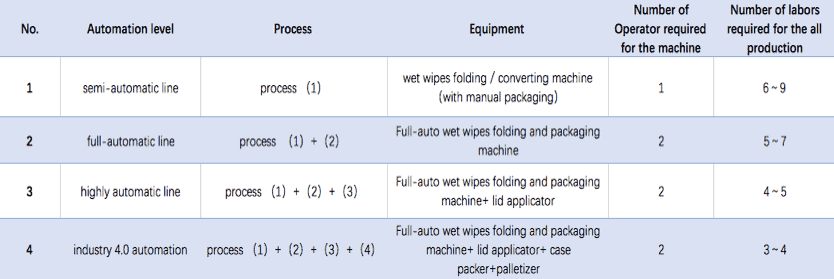

Automation Levels

Automation level can be regarded as the biggest influence on the wet wipes machine costs.

The price of a semi-automated and a full automated wet wipes machine could vary greatly.

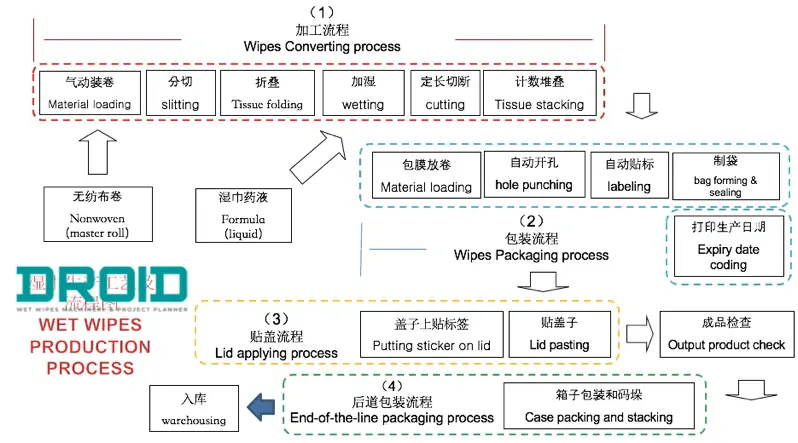

Let’s look at the wet wipes production work flow again:

A complete wet wipes production entails the following 4 processes:

- wet wipes converting process

- wet wipes packaging process

- wet wipes lid application process

- End-of-the-line packaging process

Each process aligns with equivalent automation level and the production lines.

How much Automation do you need depends on your budget frame, sales volume forecast, capacity requirement, labor cost.

Output Product Quality

What would be your ultimate expectation on a wet wipes machine?

I believe it is to get consistent quality output product at minimum wastage rate.

So what would be taken into your quality standard?

Here are some takeaways:

- Product Diversity

- Precision

- Rejects

- Leakage

- Uniformity of Unit weight

- Wrinkles on the pouch

A high-priced wet wipes machine is expected to achieve higher performance than the average.

In this case, high quality output performance should speak for itself the value of the wet wipes machine.

In most cases, you would be happy to pay more for a wet wipes machine that produces wet wipes in compliance with the quality standard of a critical customer.

Tips:

Wet Wipes Product quality performance Checklist:

- What is the tissue size range your wet wipes machine can do?

- Folded Width should be ±2mm of Standard width

- Stack should be looking brick shape visually. Zigzag type stacks are not acceptable.

- Center Sealing should be proper. There should not be any wrinkles

- Side Gusseting should be uniform.

- Leakage should not happen under high pressure

- Lid should be placed at desired location within the tolerance of ± 3mm

- The weight of unit pouch should be within the tolerance of 3~5g/bag

Workmanship

What defines the subjective value of a wet wipes machine?

It is the presence of the machine at first sight.

It is the finishes of the frame, the bearings or a shaft.

Good workmanship indicates that there’s more involved with the responsibility for precise quality control and the value speaks for itself.

Add-ons & accessories

Some of the most common “add-ons” found in the purchase of a wet wipes machine:

- Folding board

- Web guider

- Metal detector

- Checkweigher

- Vision detection system

- Printer

- Multi-dimensional bag former

- Die cutter

- Water tank

As you can see, there are many options available.

When you receive a quotation from a wet wipes machine supplier, check and compare what accessories they have included to justify a possible big price gap.

Installation& commissioning

Commissioning & installation charges vary from supplier to supplier falling in the range between 100-600usd/person/day. Travel, housing, and other logistics expenses are not included and in most cases are invoiced at actual cost to Customer.

Keep in mind to add this cost to your initial budget of buying a wet wipes machine

Side note:

Example of how Droid’s team is doing wet wipes machine installation:

A higher-than-average degree of accuracy is achieved in DROID’S pursuit of making high performance wet wipes machines throughout the process of manufacturing, installation and beyond.

Lifetime wet wipes machines cost

A buyer taking up an investment in a wet wipes production line has to find and avoid the hidden costs that are usually beneath the surface like an iceberg, and not clearly visible during the purchase process.

In most cases, you are going to run a wet wipes machines for as long as you run your wet wipes business, let’s say 8-24hours a day, 5-10 years, so you want to make sure wet wipes machine they buy will provide ultimate capacity utilization, minimum maintenance, less downtime and easy of use.

We have examined the initial price that you will pay upfront when you purchase a wet wipes machine. But if you stop there thinking they are the only costs with the goal of finding the cheapest option, you might end up having regrets down the road. Maintenance, Repair, replacement, wastage, do not forget these long-term costs that could make a big difference associated with owning a wet wipes machine.

What influences the lifetime cost of a wet wipes machine?

The long-term cost of ownership for a wet wipes machine includes significant operating costs:

Quick overview of the lifetime operating costs:

- Labor cost (operator, maintenance)

- Energy consumption

- Raw material

- Industrial space

- Planned Maintenance

- Unplanned corrective maintenance losses

- Spare parts replacement

- repairs

- Rejects

- Change-over

That’s wet wipes machine pricing in a nutshell.

Ready to receive a personalized quote for your wet wipes machine?

CLICK TO REQUEST A QUOTE TODAY.

Our trained project specialist takes the time to understand your needs budget and goals, then will recommend you the best-fit wet wipes machine model accordingly.

Personal care wipes:

Personal care wipes:  Household wipes include wipes for general purpose home care- surface disinfecting wipes, floor cleaning wipes, kitchen cleaning wipes, toilet cleaning wipes, automotive car cleaning, lens cleaning wipes, and shoe polishing wipes.

Household wipes include wipes for general purpose home care- surface disinfecting wipes, floor cleaning wipes, kitchen cleaning wipes, toilet cleaning wipes, automotive car cleaning, lens cleaning wipes, and shoe polishing wipes. Commercial/ industrial wipes include general purpose wipes, speciality wipes(Degreasing / Machinery cleaning wipes), wipes for food service and healthcare sector.

Commercial/ industrial wipes include general purpose wipes, speciality wipes(Degreasing / Machinery cleaning wipes), wipes for food service and healthcare sector.

Dear DROID team,

I hope this email finds you well.

My name is Moaid Twaiq, and I am reaching out to express my appreciation for the excellent services your company provides in the production lines manufacturing industry. I have recently embarked on a new venture in the wet wipe manufacturing business and have been thoroughly impressed by your consultation service to your customer specially new comers to the business like myself.

Having thoroughly researched various manufacturers, I am particularly interested in exploring a potential business with your esteemed company. I believe that your expertise and experience in production lines for wet wipes could greatly benefit my business.

Therefore, I kindly request you to provide me with a business model proposal tailored to my specific requirements. As a newcomer to this industry, I am seeking guidance on the most suitable production line options, cost estimates, and any additional services or support your company offers.

I would greatly appreciate it if you could include the following details in your proposal:

1. Overview of the production lines suitable for wet wipe manufacturing

2. Pricing structure, including equipment costs and any ongoing maintenance fees

3. Lead time for manufacturing and delivery

4. Warranty and after-sales support options

5. Any additional services or customization options available such as overview about operational cost.

Furthermore, if you have any success stories or references from other clients in the wet wipe manufacturing industry, I would be delighted to review them. This will help me gain a better understanding of your company’s capabilities and the potential benefits of partnering with you.

I am eager to learn more about your offerings and discuss the possibilities of collaboration.

Thank you for your attention to this matter. I look forward to receiving your business model proposal and exploring the potential of working together.

Best regards,

Moaid Twaiq

00962797226670

00966550063888

[email protected]