#1: Flexibility in Production Capacity

The key to scaling up in the wet wipes industry lies in the ability to adjust production capacity on the fly, without compromising on quality or efficiency. This flexibility is critical in a market that is prone to sudden shifts in demand due to changing consumer preferences, seasonal variations, or unforeseen events. By leveraging this flexibility, companies can respond quickly and effectively to changing market conditions, ensuring their continued success in the industry.

Wet wipe manufacturers can benefit from a flexible manufacturing environment that utilizes scalable wet wipe machines. These machines can increase production to meet demand during busy periods or high-quality seasons, while still maintaining product availability. Conversely, during slower times, manufacturing capacity can be reduced to minimize wasteful resource use and operating expenses.

Being adaptable is crucial for both long-term and short-term planning. Wet wipes machines that can quickly adjust to changes in customer behavior and market dynamics have a competitive advantage. By avoiding overproduction during slow periods, wet wipes manufacturers can reduce waste and minimize surplus inventory. This results in a more efficient and cost-effective operation.

Additionally, the ability to be flexible in production aligns with sustainable goals. Wet wipe manufacturers can reduce their environmental impact by utilizing resources efficiently following demand. This resource optimization goes beyond the plant floor and encompasses raw materials, energy consumption, and overall operating efficiency.

#2: Energy Efficiency

Producing wet wipes sustainably requires paying close attention to energy efficiency, which can significantly impact the environment. Energy efficiency in wet wipe machines refers to the process of optimizing energy usage during production to reduce operational expenses and environmental impact.

Advanced technologies are utilized in the development of wet wipe machines that can be scaled up while maintaining energy efficiency. These technologies include power management systems, variable speed drives, and intelligent controls. The intelligent controls enable accurate monitoring and adjustment of energy consumption, using energy only when necessary. Variable speed drives allow the equipment to run at varying speeds depending on the workload, which reduces energy usage during periods of slow production.

One of the primary benefits of using energy-efficient devices in the wet wipes business is the lower total carbon footprint. Wet wipe manufacturers can reduce their energy use, which contributes to a more environmentally friendly and sustainable production process. This helps establish the sector as a responsible steward of limited resources and aligns with international efforts to mitigate climate change and comply with environmental standards.

Moreover, incorporating energy-efficient technology in the wet wipes manufacturing process not only benefits the environment but also saves companies significant costs. By reducing energy consumption, the overall operational expenses of the industrial sector can be lowered, which ultimately improves its economic sustainability. The use of energy-efficient wet wipe machines is a strategic decision that promotes a balance between profitability and social responsibility, serving both economic and ecological objectives.

#3: Raw Material Optimization

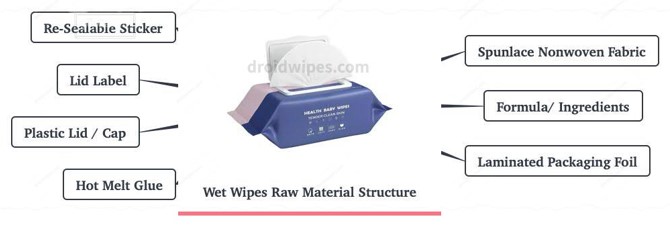

One of the key factors in the sustainable production of wet wipes is the efficient use of wet wipes raw materials, which is essential in reducing waste and minimizing the impact on the environment. In the context of wet wipes machines, this optimization involves adopting innovative strategies to improve the utilization of wet wipes raw materials, leading to a more cost-effective and eco-friendly wet wipes manufacturing process.

The purpose of scalable wet wipe machines is to optimize the use of raw materials during different stages of manufacturing. These machines incorporate devices for precise cutting and sizing, which minimize the amount of excess material used. By reducing mistakes and ensuring consistent product quality, advanced automation technologies also aid in optimization by minimizing the need for rework and the associated waste.

Raw material optimization is not limited to the factory floor, as it encompasses the entire supply chain. Strategic sourcing is employed by manufacturers to work closely with suppliers and acquire high-quality resources in a cost-effective and ecologically friendly manner. The use of recyclable or biodegradable components in the production process also caters to consumer demand for environmentally friendly products, thereby enhancing the sustainability of the wet wipes industry as a whole.

Optimizing raw materials yields two benefits. Firstly, it addresses environmental issues by reducing the ecological impact associated with the extraction, processing, and disposal of raw materials. Secondly, it promotes economic sustainability by reducing material waste, cutting production costs, and improving the overall efficiency of industrial processes.

#4: Automation and Innovation

Modern wet wipes production is undergoing significant changes with the integration of innovation and automation in the wet wipes manufacturing process. This transformation is leading to increased productivity, sustainability, and product quality. With the help of automation and cutting-edge technology, the wet wipes machine industry is being revolutionized, optimizing production procedures and catering to the changing needs of consumers.

Scalable wet wipe machines are designed to utilize automation in various stages of the wet wipes manufacturing process. Automated equipment has reduced the need for human intervention in processes such as material feeding, cutting, folding, packing, and quality checking. This has resulted in a decrease in the chance of errors, improved production speed and accuracy, and consistent product quality.

Innovations in the manufacturing of wet wipes go beyond automation. They include advanced features that address specific problems in the industry. For instance, some devices are equipped with advanced sensors that can detect and correct flaws immediately, reducing waste and improving output efficiency. Furthermore, improvements in packaging materials and design are helping to achieve sustainability goals by minimizing their negative impact on the environment.

Wet wipes manufacturers are changing the way they approach manufacturing by integrating robots and artificial intelligence (AI) into wet wipe machines. AI-driven systems analyze data to optimize production schedules and resource utilization, while robots perform complex jobs quickly and precisely, increasing productivity and enabling producers to swiftly adjust to shifting consumer needs.

Automation and innovation not only affect the production floor but also have an impact on the entire company ecosystem. Wet wipes manufacturers benefit from lower labor costs, safer working conditions, and round-the-clock operations without the need for human involvement. This makes the company model more robust and flexible, which benefits long-term sustainability as well as increasing productivity.

#5: Adaptability to Regulatory Changes

Wet wipes manufacturers must be able to adapt to changing regulations as the industry is subject to varying requirements for product safety, environmental impact, and sustainability. To comply with an ever-changing regulatory environment, scalable wet wipe machines are essential for manufacturers as they allow their operations to be flexible and responsive to new demands.

Regulatory amendments may cover a wide range of topics such as requirements for eco-friendly packaging and disposal methods, or restrictions on certain substances or materials used in wet wipes. The modular and adaptable architecture of scalable wet wipe machines makes it easy to update and modify them to comply with new regulations. Wet wipes manufacturers can quickly respond to changes by implementing modifications to their manufacturing processes, ensuring compliance and reducing the risk of non-compliance.

Wet wipe manufacturers can now easily keep themselves updated with regulatory changes by using advanced monitoring and control systems in scalable wet wipe machines. These systems provide real-time data on various production process factors, enabling quick modifications in response to changing requirements. Scalable machines ensure that manufacturers can adapt to regulatory changes without compromising their operations, whether it involves making changes to the formula, adjusting production parameters, or adding new safety measures.

Moreover, the collaboration between wet wipe manufacturers and regulatory agencies is also made easier with the use of scalable wet wipe machines. By using flexible and upgradeable equipment, manufacturers can showcase their commitment to compliance, establishing themselves as industry leaders in ethical and legal manufacturing practices. This also helps to gain the confidence of authorities in their compliance efforts.