Technology Behind Sustainability in Wet Wipes Industry

Step Into The Future of Sustainable Wet Wipes Ahead of Your Competition

Wet wipes have become a necessary utility in everyone’s daily life. What began as a simple method to wipe a baby’s bottom is now applied to a variety of tasks, including cleaning computers, shining leather, clearing dirt, disinfecting tables, and cleaning off dirty hands. They have taken over as the standard cleaner for road trips and cleaning vehicle panels, but they may also be utilized as a temporary “bath” while travelling, for intimate usage, to care for the elderly, and, yes, as a substitute for toilet paper for adult bottoms.

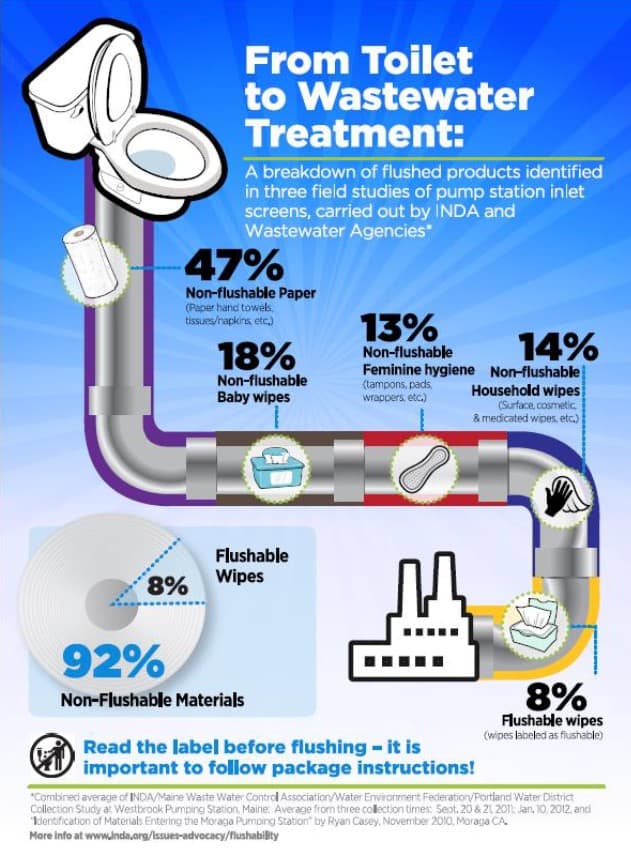

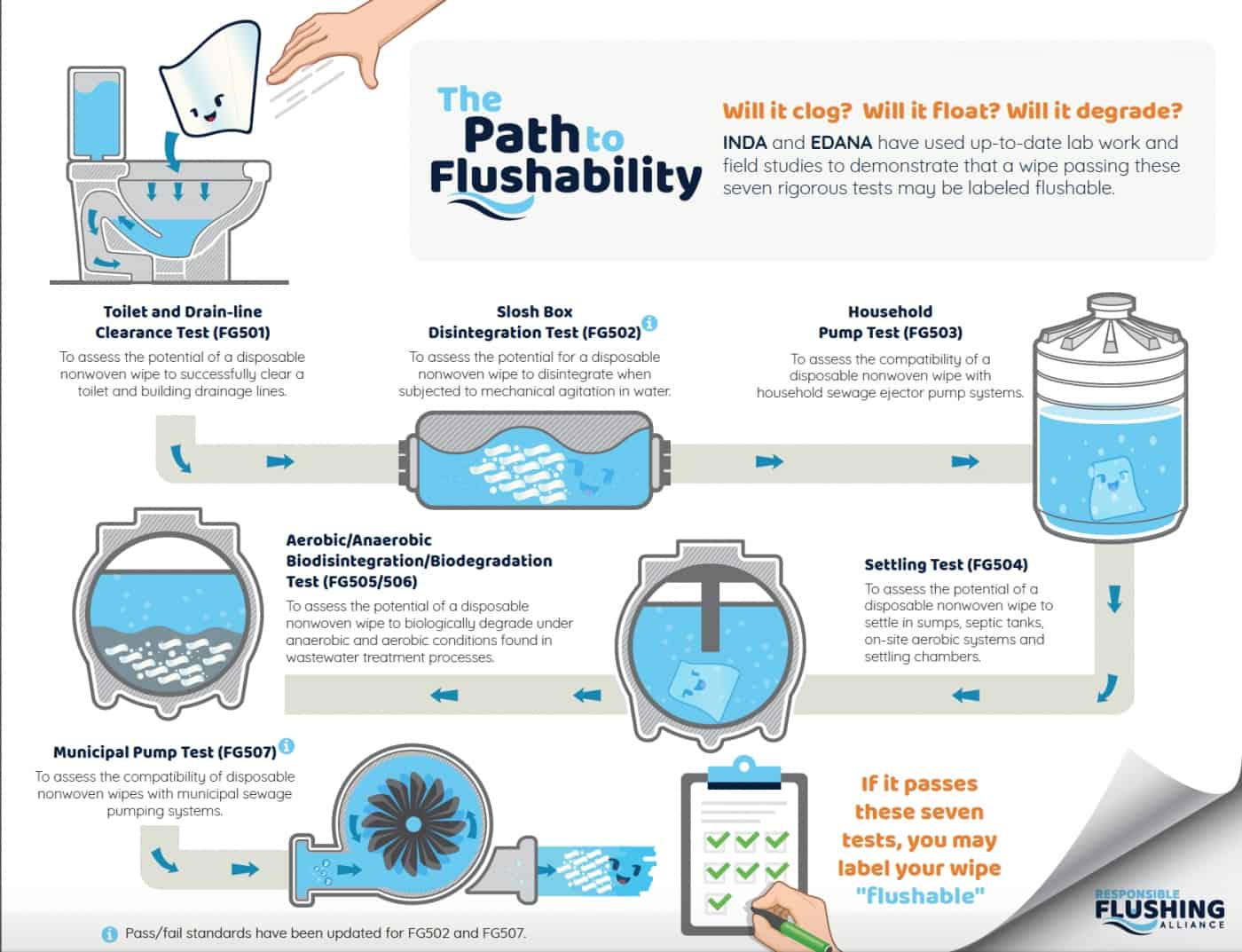

Wipes are anticipated to be a $21.9 billion market by 2022 as a result of their growing demand. As global demand for wet wipes increases, their underlying environmental concern arises as traditional wet wipes do not decompose in the environment and might cause a mess to sewer systems when flushed into the toilet.

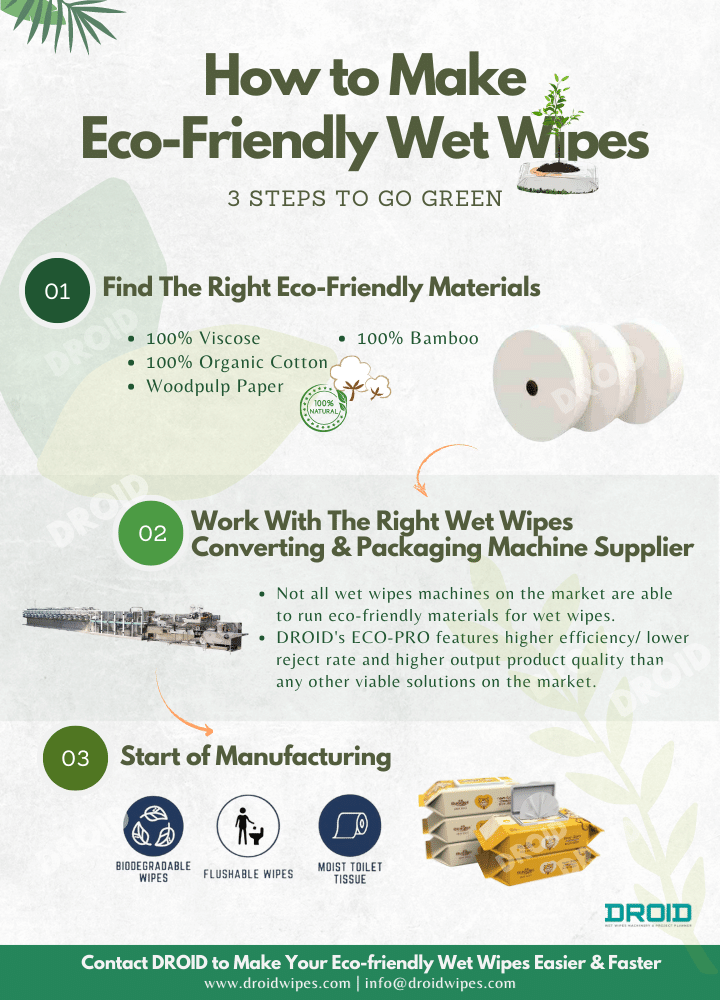

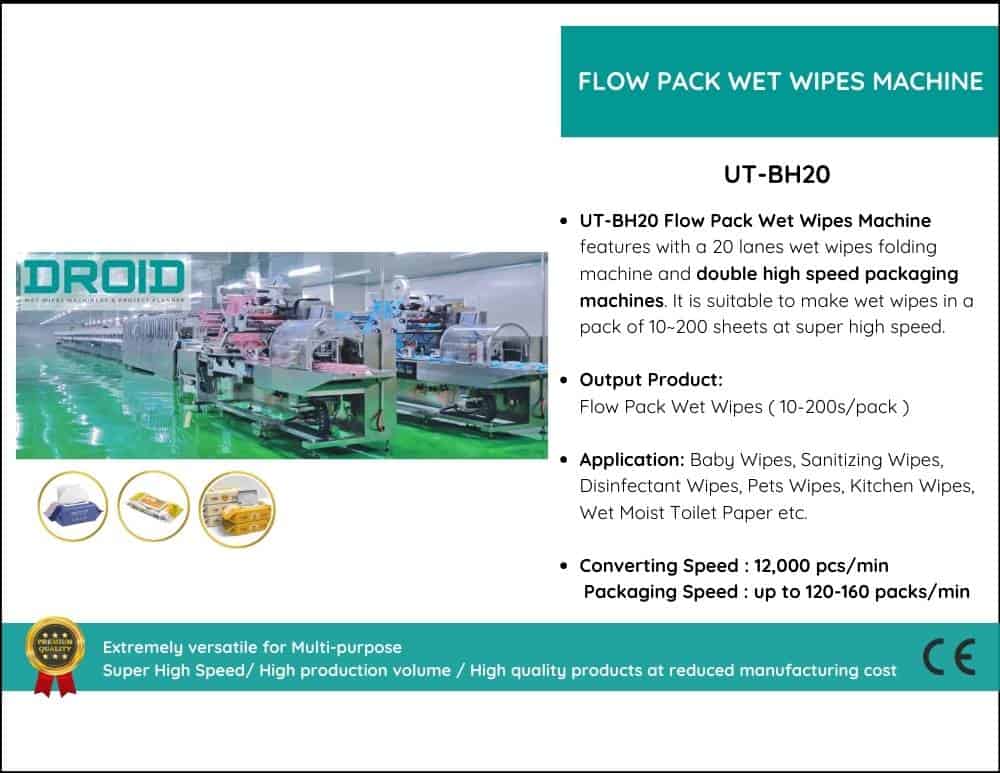

To DROID, we remain committed to sustainability and continue to innovate on wet wipes converting and packaging technology to improve global wet wipes producers’ experience with eco-friendly wet wipes (plastic-free wet tissue) manufacturing.

By providing one of the most efficient and advanced Eco-friendly wet wipes production lines, more and more wet wipes manufacturers are able to make plastic-free wet wipes, fine-to-flush wet toilet tissue and biodegradable wet wipes in a more efficient and sustainable way. Each DROID member is overjoyed to find the presence of a growing number of plastic-free wet wipes in the market. We are a firm believer that wet wipes can be utilized to a standard that fulfils safety, responsible, and sustainability via our continuous innovation on the technology that stands behind.