PRODUCT DETAILS

Features

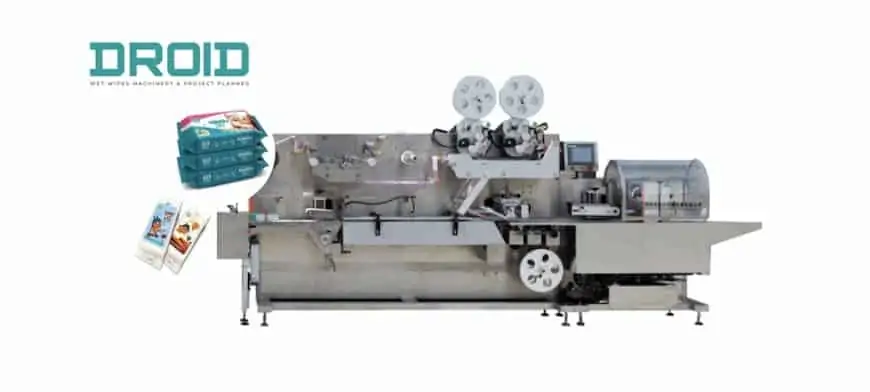

UT-WP High speed flow wrap wet wipes packaging machine is specially designed to pack a broad range of wipes dimensions at the speed of 100packs/min.

Compatibility

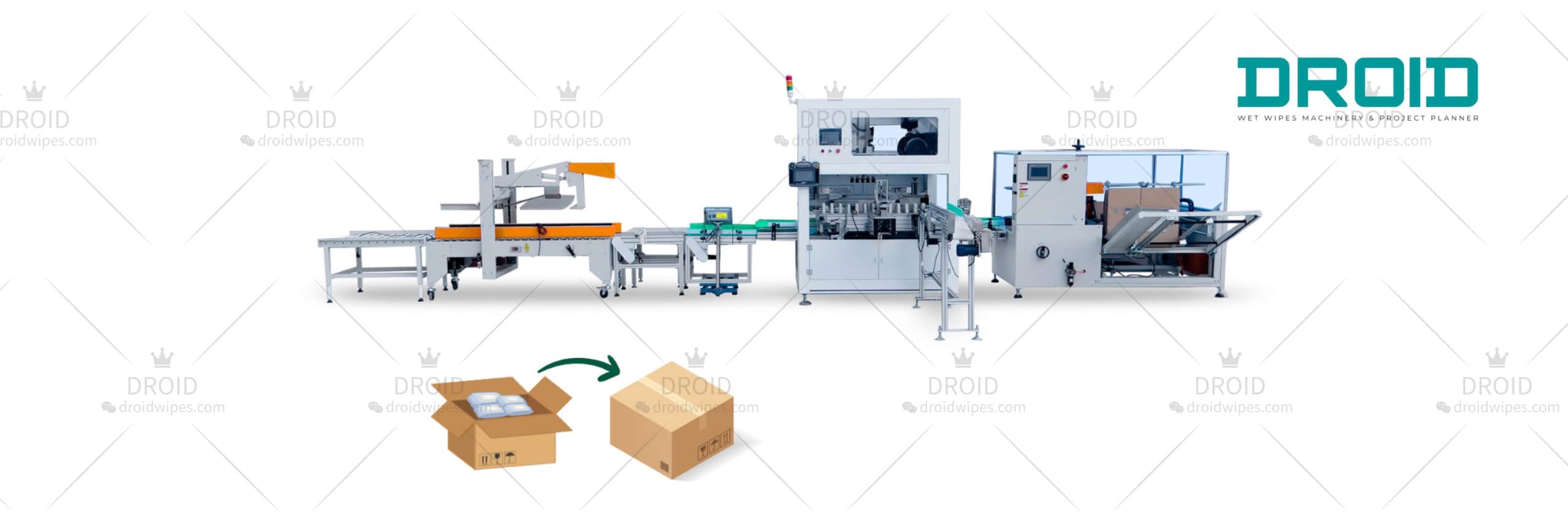

UT-WP wet wipes packaging machine can be connected to any wet wipes converting machine to do flow wrap packing

Can we pack different sizes on this machine?

Packing Length:100-350 mm (Adjustable)

Packing Width: 35-120 mm (Adjustable)

Packing height: 5-130 mm (Adjustable)

High Speed

- UT-WP capacity speed is able to reach 100packs/min.

Output Product

1-150wipes/pack. (Max Height 130mm)

Highly Automation

- UT-WP wet wipes packaging machine adopts s

- Highly automated with no need for human interference throughout the production process.

Ease of Operation

- Packing length and width size changed by servo system, no mechanical adjustment needed

- Easy and quick change over between different formats

- Machine stops automatically when machine breaks down

- User-friendly HMI with touch screen

- Visual & audible warning systems

In compliance with FDA GMP Norm

- Machine design is in compliance with FDA GMP hygiene & safety standard catering to contract manufacturing needs of International Brands.

- All conveyor belts are food-grade, anti-bacterial for hygienic product transfer

- 304L Stainless steel is applied to the cover of machine and main spare parts in contact with lotion and fabric

Great Capacity Utilization

- Labor-free auto film splice system makes for non-stop operation, a great capacity utilization with minimum manpower and wastage rate.

Great Flexibility

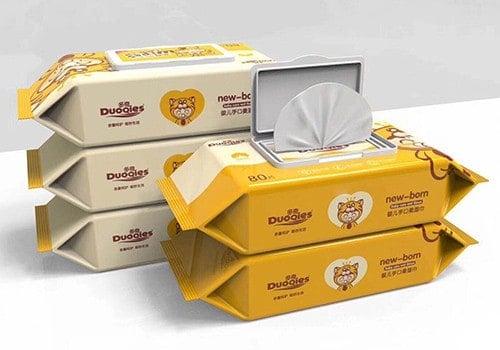

- Output Product: All types of wet tissue (1-150 wipes/pack)

- UT-WP wet wipes packaging machine is designed to make a vast variety of wet wipes in a pack of 1-150 sheets with the maximum height of 130mm such as mini wipes, pocket wipes, portable baby wipes, bed bath towel, refreshing wet tissue, skincare wet wipes, antibacterial wet wipes, disinfecting wipes, sanitizing wet wipes, makeup removal wipes, personal hygiene wipes and intimate wipes.

Structure

(1) Servo driven in-feed system (2)CPU motion control system (3)Full servo drives (9 servos) (4)Dual labeling units(5)Dual packing film units(6)Auto Splicing system(7)Auto Die cutting system (8)Multi-dimensional bag former(9)Trimming unit(10)Gusseting unit(11)Air venting unit(12)Reciprocating sealing system

Work Flow:

tissue wait-in-line→ tissue delivery to packaging machine→ bag forming →die cutting→ labeling→ gusseting →auto air → sealing→ finished product output.

CE Certification

Machine Parameters

- Model: UT-WP

- Application: specialized to pack Wet wipes (1-150pcs/pack)

- Work flow:conveying wipes to UT-WP packaging machine → setting packing film →batch code printing → setting window hole label → Central sealing →corner inserting /air takes-out → End sealing and reciprocating cut → packaging → Output finished products.

- Capacity speed: 10-100bags/min (Subject to material types)

- Wrapping material:PP,OPP,PET,PE, and all suitable films

- Shapes of packaging:flow pack

- Packing size: (100-350)x(35-120)x(5-130)mm

- Horizontal sealing pattern:reciprocating heat sealing system

- Drive motor pattern: all servo driven

- Operation interface: touch screen

- Power: AC380V 50/60Hz | 8 kw

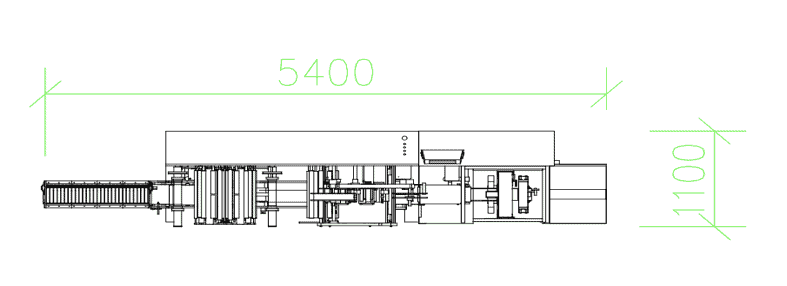

- Machine size: 5400×1100×2100mm(L*W*H)

- Machine weight: 2000kg

Machine Layout