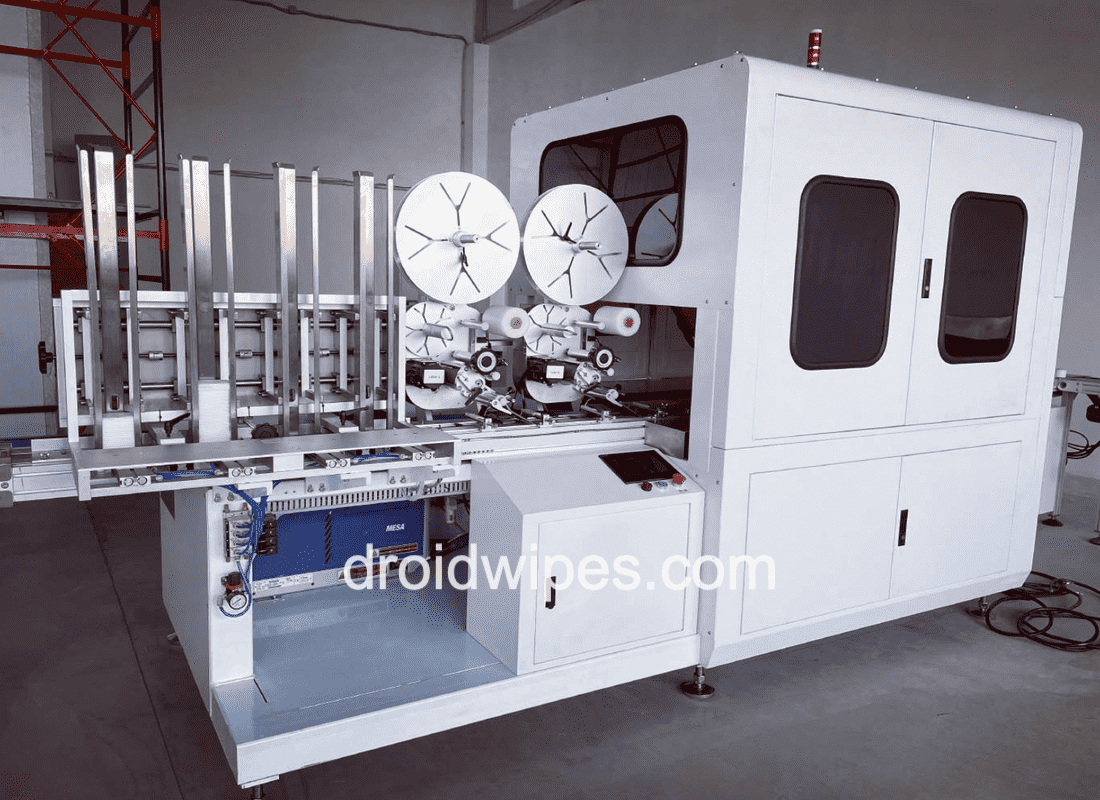

UT-LM70 Robotic Wet Wipes Lid Applicator

(Automatic Wet Wipes Capping Machine)

|Demo Video| UT-LM70 Robotic Wet Wipes Lid Applicator

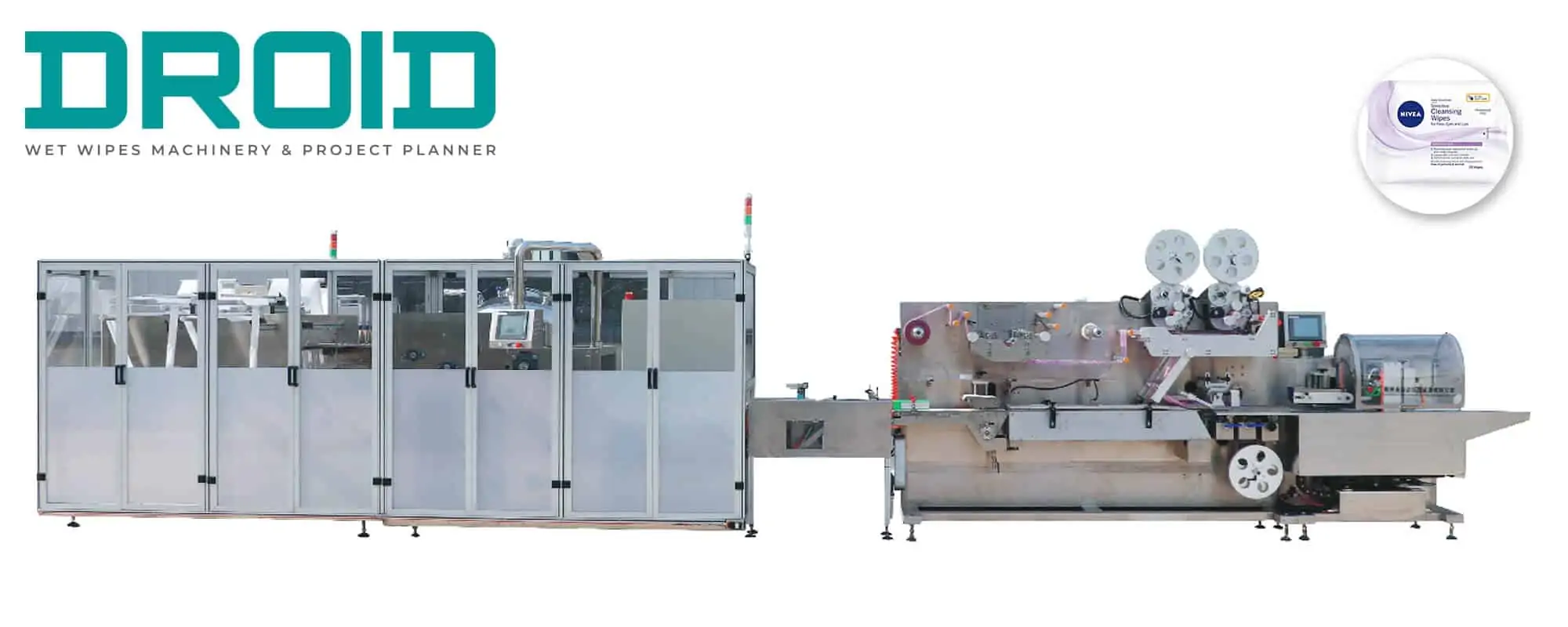

|How This Wet Wipes Lid Applicator Works| – Work Flow

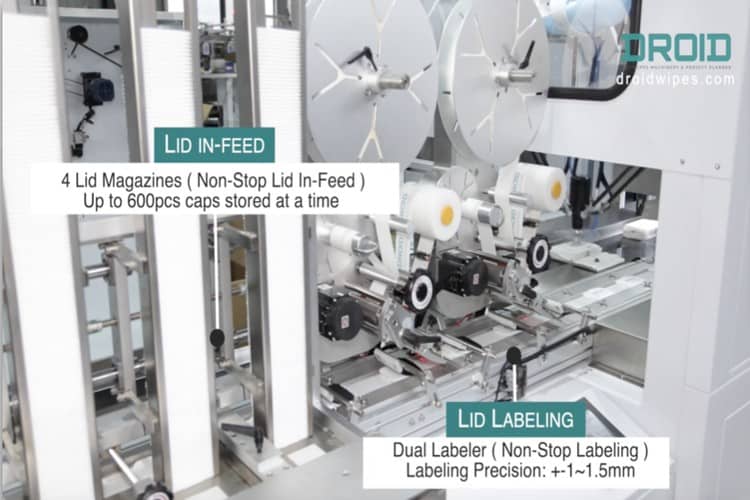

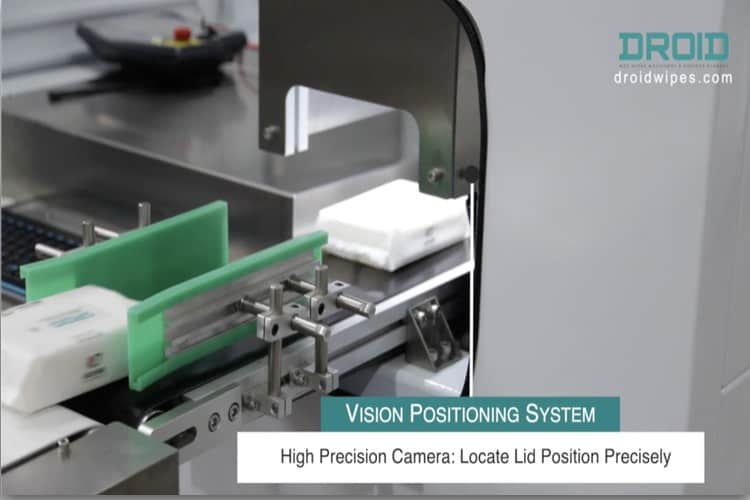

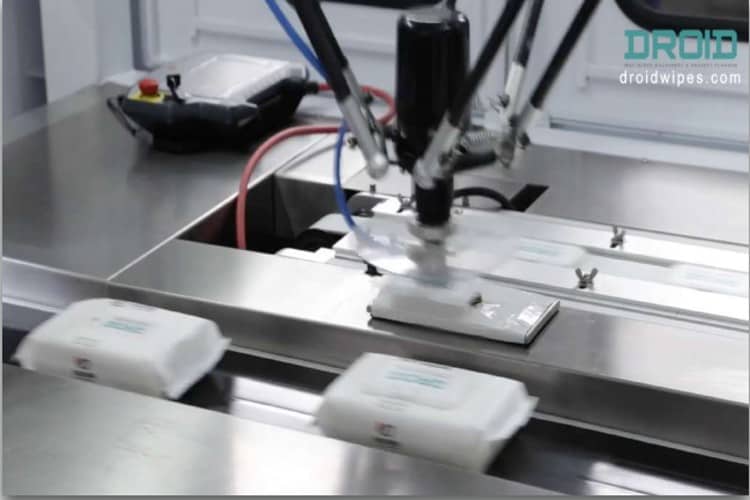

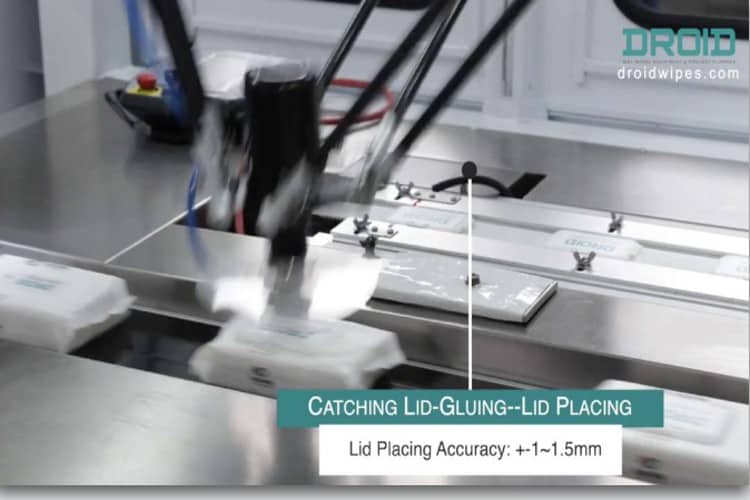

(1)Lid In-Feeding→(2)Lid Labeling→ (3)Vision Positioning →(4) Robot Catching lid→ (5)Glue spraying to the lid→ (6)Identifying Position→ (7) Robot Pasting Lid on Wet Wipes Packages→ Output Product

Lid In-Feeding→Lid Labeling

Vision Positioning

Catching lid→ Glue spraying

Identifying→ Lid applying

|Value for Money|

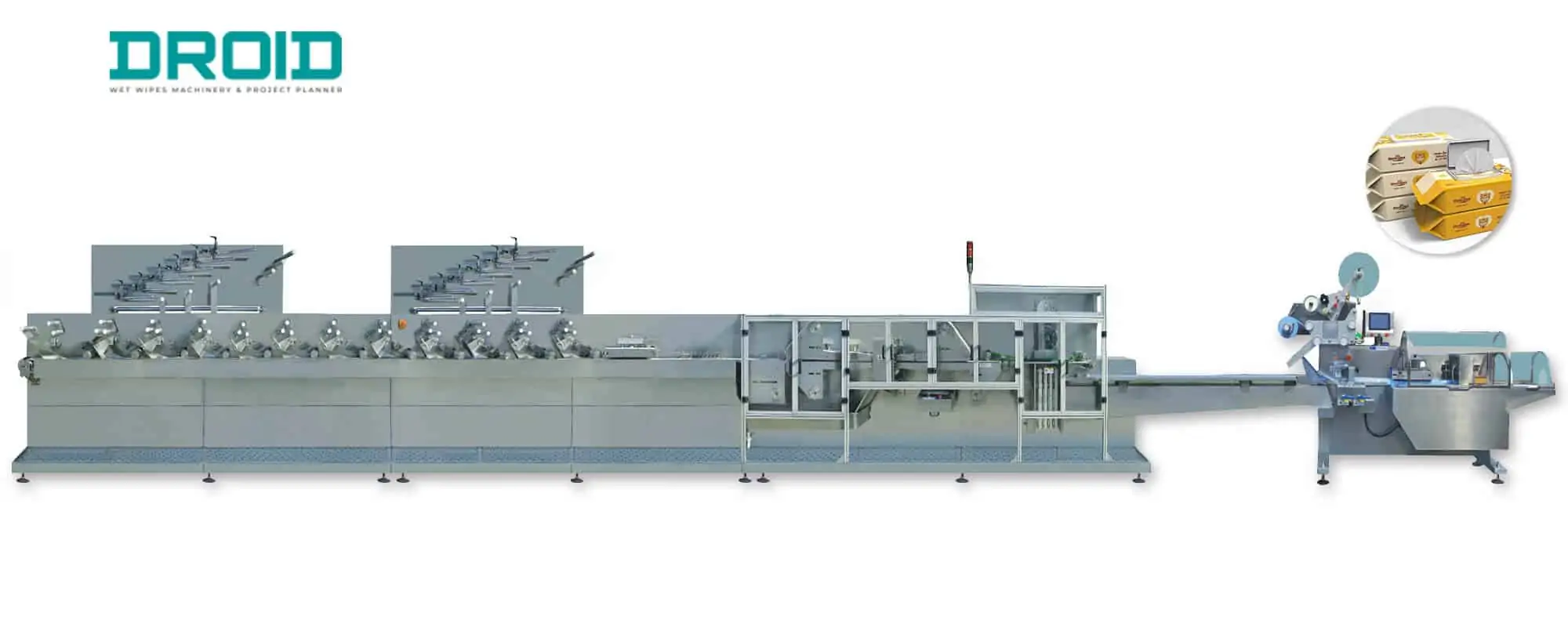

One Set of UT-LM70 Wet Wipes Lid Applicator Can be Used for All Types of Big & Small Wet Wipes Packs

All sorts of flat pack/pocket (cross-fold) wet wipe products, baby wipes, adult wipes, wet toilet tissue, make-up wipes, disinfectant wipes, anti-bacterial wipes, alcohol wipes, floor wipes, biodegradable wipes, and more.

|Features| UT-LM70 Robotic Wet Wipes Lid Applicator

UT-LM70 4-Axis Robotic wet wipes plastic lid applicator is an independent equipment, which can be connected to the end of the wet wipes packaging machine and put plastic lids on top of wet wipes.

• High Speed & High Precision

• Machine is designed to be compact and save spaces

• Machine design in compliance with FDA GMP hygiene & safety standard

• Full Servo driven and PLC control system

• Highly automated with no need for human interference throughout the production process • Diverse shapes and sizes of plastic lids are workable on the machine

• Easy and quick change over between different formats ( Within 10 Minutes )

• Visual & audible warning systems

• User-friendly HMI with touch screen

• The gluing pattern and gluing amount can be adjusted

MITSUBISHI (Japan)

KEBA(Austria)

Nordson (U.S.A)

SCHNEIDER(France)

| Machine Details|- UT-LM70 Wet Wipes Lid Applicator

| Parameters |- UT-LM70 Wet Wipes Lid Applicator

| Model | UT-LM70 |

| Output product type | Wet Wipes with Flip Top Lid |

| Robot Type | Delta (4-Axle) Spider Robot |

| Capacity | Single Sucker: up to 70pcs/min Double Suckers: up to 110pcs/min |

| Lid placing accuracy | +1.5mm |

| Labeling accuracy | +1mm |

| Gluing System | Nordson ( U.S.A ) ( Or other international brand ) |

| In-feed Wipes Package Dimensions | (110-350)x(70-140)x(5-115) mm ( LxWxH ) |

| Lid Dimensions | (50-150)x(50-120)x(2-10) mm ( LxW ) |

| Power | AC220V 50/60Hz | 8kw |

| Air Consumption | 0.6~0.8MPA ; 500L/Min |

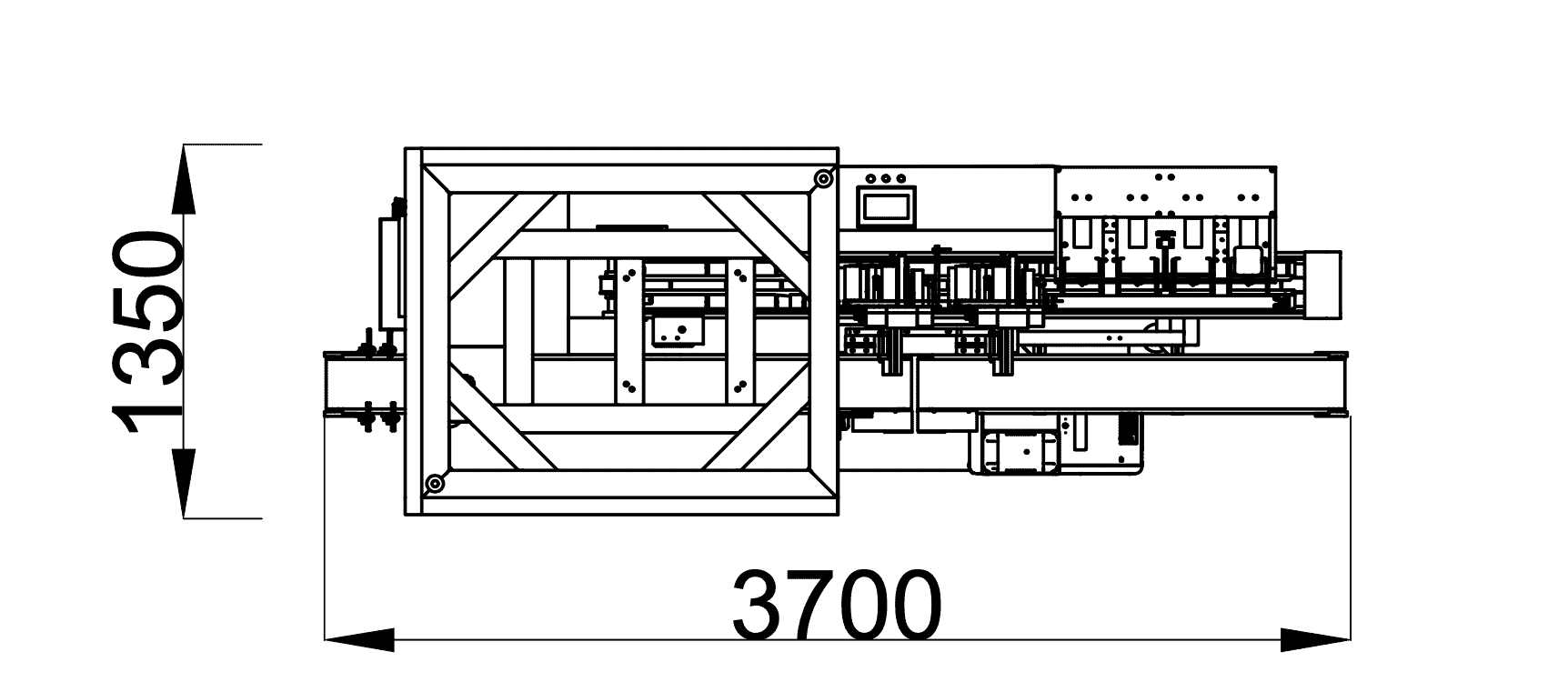

| Machine size | 3,700*1,350*2,000mm |

| Machine weight | 1,400kg |

| Machine Layout | UT-LM70 Wet Wipes Lid Applicator

Do You Still Have Questions? We Can Assist You!

Our sales staff is here to help if you can’t find the answer you’re looking for. Please contact us if you have any questions about our products, prices, or anything else; we would be happy to assist you!