UT-FL2 Cross-fold Wet Wipes Machine Running Demo

PRODUCT DETAILS

Features

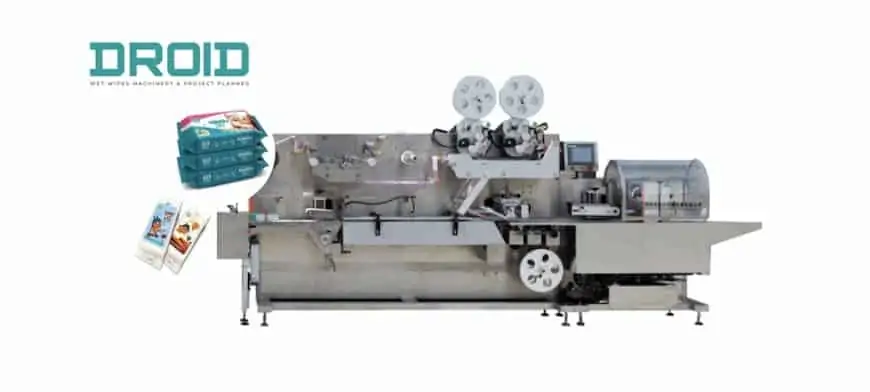

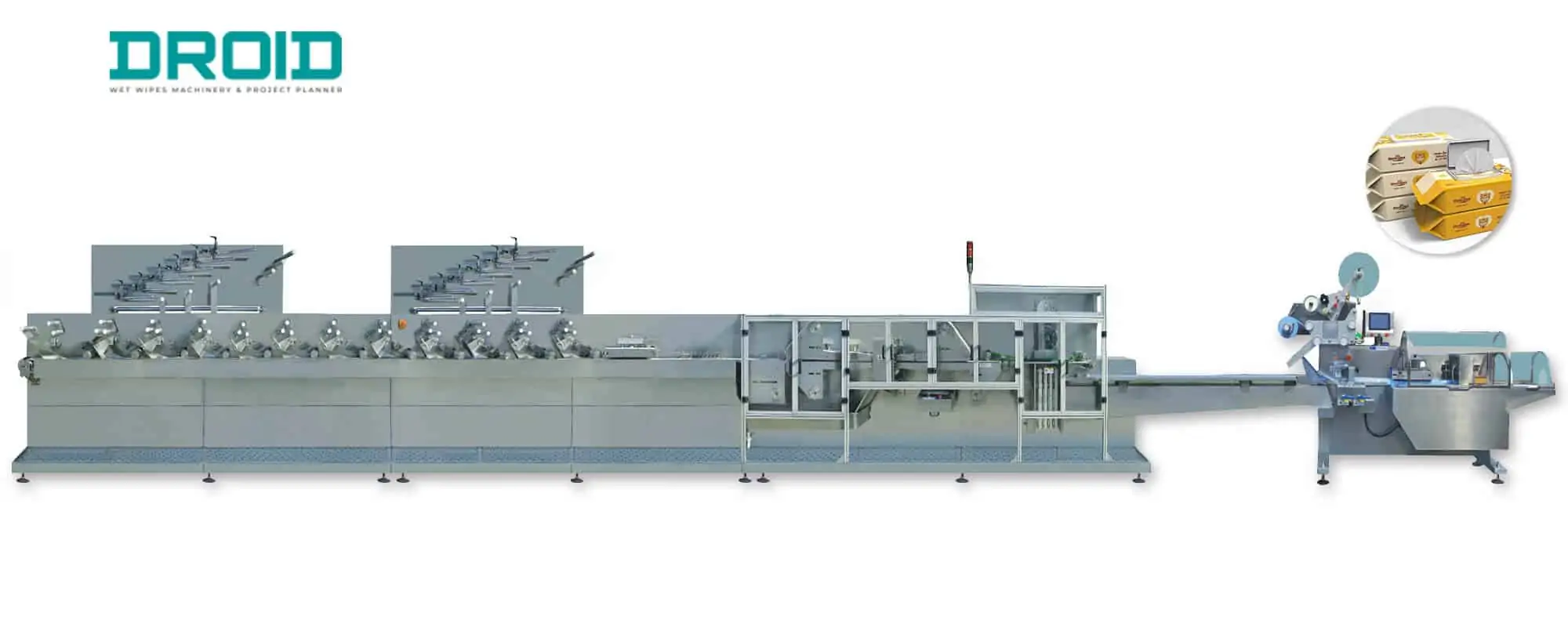

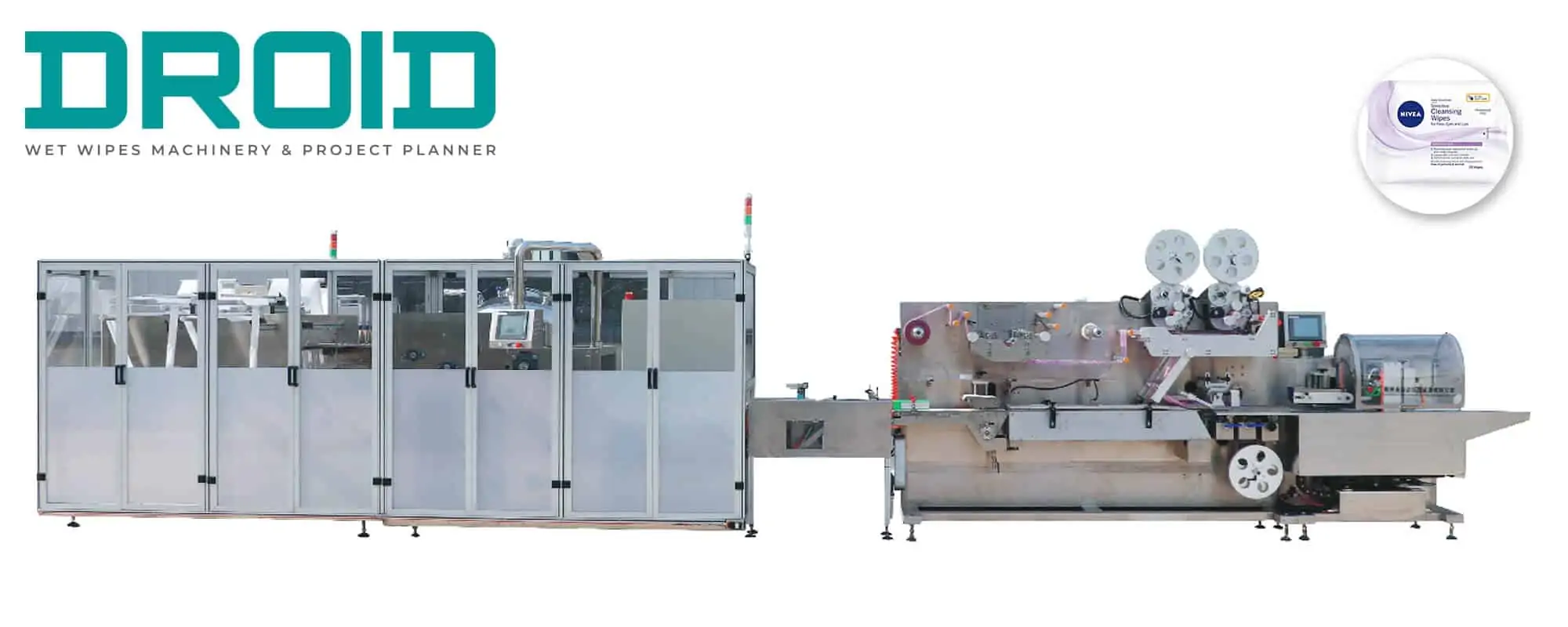

UT-FL2 automated crossfold wet wipes machine is composite of one converting machine and one packaging machine.

It is capable of producing pocket sized wet wipes in a broad range of product dimensions at the speed of 1000pcs/min on converting machine and 100packs/min on packaging machine.

UT-FL2 features a great flexibility as it is designed to make a vast variety of wet wipes in a pack of 5-40 sheets such as mini wipes, pocket wipes, portable baby wipes, bed bath towel, refreshing wet tissue, skincare wet wipes, antibacterial wet wipes, disinfecting wipes, sanitizing wet wipes, makeup removal wipes, personal hygiene wipes and intimate wipes.

- Output Product: all types of wet tissue (5-40pcs/pack)

- Structure:Wet tissue converting machine +Flow wrap wet wipes packaging machine

- Machine design in compliance with FDA GMP hygiene & safety standard

- Full Servo driven and CPU control system

- Highly automated with no need for human interference throughout the production process

- Precise wetting system: deviation of +-3g per pack

- Tissue & Packing length and width size changed by servo system, no mechanical adjustment needed

- All conveyor belts are food-grade, anti-bacterial and suitable for hygienic product transfer

- 304L Stainless steel is applied to the cover of machine and main spare parts in contact with lotion and fabric

- Easy and quick change over between different formats

- User-friendly HMI with touch screen

- Visual & audible warning systems

- Machine stops automatically when machine breaks down

- Structure: (1) raw material loading device(2) Automated raw material change-over system; (3)tension device, (4) folding device, (5) Quantitative wetting system, (6) automatic counting device, (7) auto die cutting unit, (8) auto labeling unit,(9) auto film change-over system(10) Auto-Electrical eye tracking (11) Auto air-rejection unit;(12) servo driven sealing unit for finished products.

Work Flow:

Automated Nonwoven loading→ tension control → tissue slitting →tissue folding→ Precise online wetting→ tissue cutting→ tissue stacking & counting →tissue wait-in-line→automated tissue delivery to packaging machine→ bag forming →die cutting→ labeling→ gusseting →auto air venting → sealing→ finished product output

Product Parameters

- Model: UT-FL2

- Output product type:5-40wipes/pack

- Capacity: Converting speed: 1000 pcs/min | Packaging speed: 100packs/min

- Automatic Non-stop raw material change-over system

- Loading station:Two rolls;one running,one standby

- Full automatic: 2 lanes tissue converting machine + one flow pack packaging machine (No Human Touch)

- Control system:CPU + Full servo driven system

- Suitable material: [35-80gsm] spun-lace nonwoven/ biodegradable material

- Open tissue size:(140-200)x(100-200) mm

- Folded tissue size: (70-100)x(40-100) mm

- Packing size:(100-200)x(40-105)x(5-80)mm

- Folding ways: CrossFold

- Power: AC380V 50/60Hz | 15kw

- Wetting system: Quantitative online-wetting

- Operation interface: Swing arm touch screen

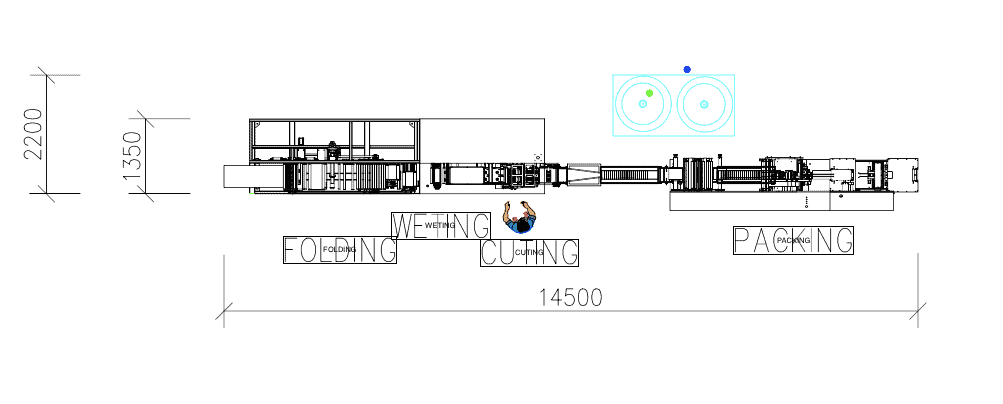

- Machine size: 14500×1350×2100mm(L*W*H)

- Machine weight: 6500kg

Mini Wipes (5pcs/pack)

Output Product:

Personal care wipes:

Baby wipes

Bed bath wet towel

Disinfectant wipes

Antibacterial wipes

Medicare wipes

Hand sanitizing wet wipes

Beauty wipes

Hygiene Wet Wipes

Feminine wipes

Pets wipes

Biodegradable wet wipes

Machine Layout

Do You Still Have Questions? We Can Assist You!

Our sales staff is here to help if you can’t find the answer you’re looking for. Please contact us if you have any questions about our products, prices, or anything else; we would be happy to assist you!

What is the production capacity of the UT-FL2 machine?

-

Converting Machine: 1000 pieces per minute

-

Packaging Machine: 100 packs per minute

What types of wet wipes can the UT-FL2 produce?

It can produce mini wipes, pocket wipes, portable baby wipes, bed bath towels, refreshing wet tissues, skincare wipes, antibacterial wipes, disinfecting wipes, sanitizing wipes, makeup removal wipes, personal hygiene wipes, and intimate wipes.

What is the product size range and packaging capacity?

The machine is adaptable to package wipes ranging from 5 to 40 sheets per pack.

What materials are the machine’s components made of?

FDA-compliant 304L stainless steel is used to make all essential parts, particularly those that come into contact with lotion or cloth.

Is the UT-FL2 machine fully automated?

Yes, throughout the manufacturing process, the machine needs very little human interaction since it is highly automated.

Does the UT-FL2 have servo-driven systems?

Yes, it makes use of a comprehensive servo-driven system that is managed by a CPU, ensuring proper control and effective functioning.

How precise is the wetting system?

The wetting system has a precision deviation of ±3 grams per pack, guaranteeing constant quality.

How user-friendly is the operation of the machine?

The UT-FL2 features an intuitive HMI touchscreen for comfortable procedure and fast format modifications.

What happens if the machine encounters an issue during production?

In the event of a malfunction, it automatically stops, has visual and auditory warnings, and uses the HMI to deliver diagnostic alerts.

How long does it take to switch between different wipe formats?

The machine’s servo-controlled format changes allow for simple and rapid changeovers, which are usually accomplished in a matter of minutes without the need for mechanical modifications.

Are the conveyor belts hygienic and suitable for personal care products?

Conveyor belts are really antimicrobial, food-grade, and specifically made for the movement of sanitary products.

Does the UT-FL2 comply with hygiene standards?

Yes, UT-FL2 machine meets FDA GMP standards for hygiene and safety.

Can the UT-FL2 machine be customized according to specific product requirements?

Yes, the UT-FL2 machine delivers a great deal of versatility and may be customized to fit certain product specifications and dimensions.

What warranty and after-sales support are provided with the UT-FL2?

During the purchase process, it is important to get clarification on warranty durations, after-sales services, spare component availability, and maintenance training specifics.

Can I see the machine in operation or receive a sample product?

Demonstrations and sample product runs are typically available upon request.