PRODUCT DETAILS

Features

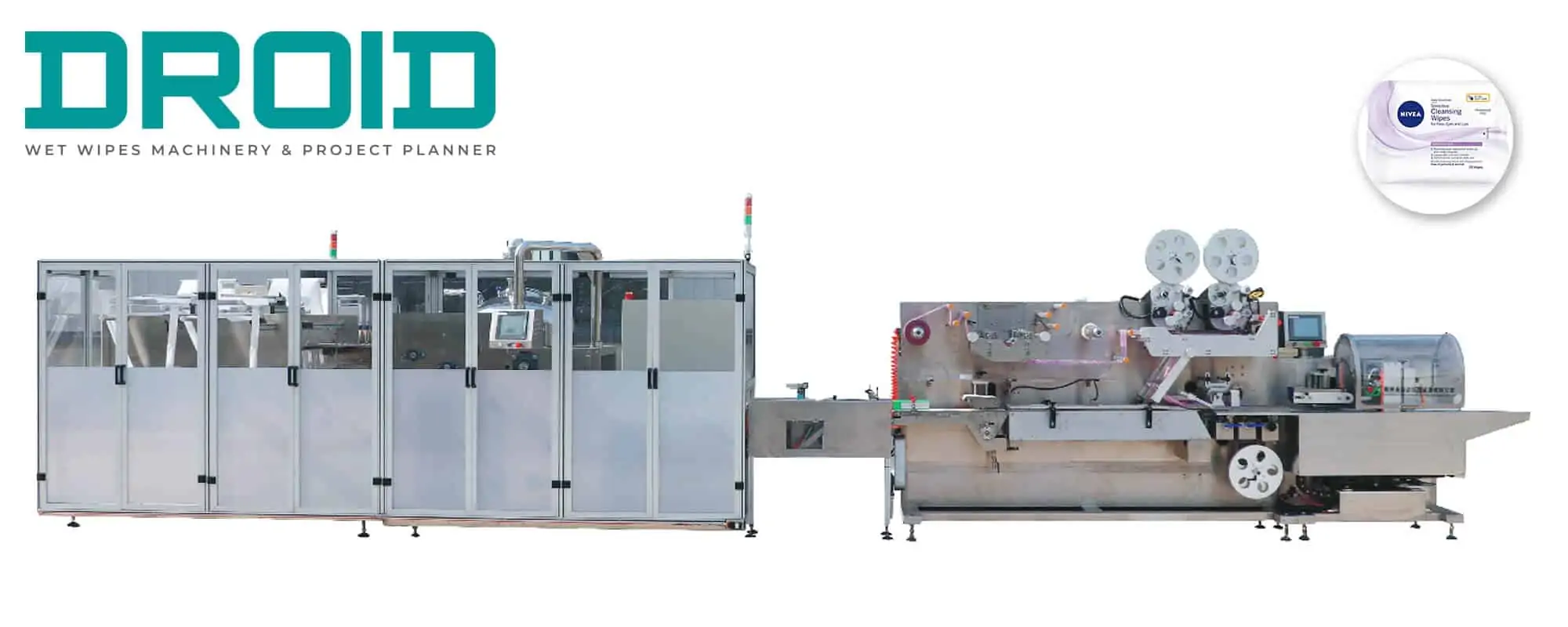

DH-L300 4-Axis Spider Robot wet wipes plastic lid applicator (capping machine) is an independent unit that can be connected to any flow pack wet wipes packaging machine to apply plastic lids on top of packed wet wipes.

- DH-L300 Wet wipes capping machine is designed to be compact and save spaces

- Machine design is in compliance with FDA GMP hygiene & safety standard

- Full Servo driven and PLC control system

- Highly automated with no need for human interference throughout the production process

- All conveyor belts are food-grade, anti-bacterial and suitable for hygienic product transfer

- Diverse shapes and sizes of plastic lids are workable on the machine

- Easy and quick change over between different formats

- Visual & audible warning systems

- User-friendly HMI with touch screen

- The gluing pattern and gluing amount can be adjusted

- Structure: (1)4-Axis movement Robot arm; (2)Vision system;(3) Labeling unit;(4) Hot melt gluing unit;(5) Lid Magazine;(6) Input & Output conveyor;(7) HMI with touch screen

Machine Parameters

- Model: DH-L300

- Application: Automatically applying Lid(Cap) on wet wipes pouch

- Robot arm: 4 Axle (Spider Robot )

- Capacity Speed: 60-75pcs/min

- Work flow: labeling- catching lid- glue spraying- identifying -lid applying Capacity: 55~70pcs/min (Single sucker)

- Control system:PLC + Full servo driven system

- Operation system:Panasonic control system

- Applicable label size range: Length: 50-100mm; Width 40-100mm.

- Applicable: wet wipes size: Length: 50-300mm, Width: 50-160mm, Height: 20-80mm.

- Applicable lid types: multiple types/sizes

- Lid thickness:5~10mm; Width:20~100mm;

- Length:20~150mm Positional deviation: within ±1mm

- Wastage:

- Max400pcs storage.

- Power: 220v/50Hz | 8.5kw

- Operation interface: 19 inch display of Human-computer

- Machine size: 3100*1500*2100mm (L*W*H)

- Machine weight: 1500kg

Do You Still Have Questions? We Can Assist You!

Our sales staff is here to help if you can’t find the answer you’re looking for. Please contact us if you have any questions about our products, prices, or anything else; we would be happy to assist you!

What is the DH-L300 Spider Robot Wet Wipes Lid Applicator?

The DH-L300 is an innovative robotic system that picks, places, and seals plastic lids onto wet wipes packaging with great speed and accuracy.

What types of lids can the DH-L300 handle?

It can handle a wide range of plastic flip-top lids used in wet wipes packaging, including various forms and sizes.

What is the operating speed of the DH-L300?

The machine can apply lids at rates ranging from 60 to 100 packs per minute, depending on the lid size and package type.

What are the key technical specifications of the DH-L300?

- Speed: Up to 100 packs per minute

- Lid Placement Accuracy: ±0.2mm

- Power Supply: 220V/380V, 50/60Hz

- Air Pressure Requirement: 0.5-0.7 MPa

- Robot Type: 4-axis high-speed spider robot

- Control System: PLC with touchscreen interface

- Material Compatibility: PET, PP, PE-based lids

Does the machine support different packaging lines?

Yes, the DH-L300 may be connected into many wet wipes manufacturing lines and conveyor belt systems.

Is the DH-L300 easy to operate?

Yes, it has a user-friendly PLC touchscreen control panel that enables simple setup, real-time monitoring, and problem-solving.

How does the lid applicator ensure accurate placement?

The machine employs vision-guided robotics and servo-driven precision control to ensure great accuracy in lid placement.

Can the machine handle multiple lid sizes without major modifications?

Yes, it enables rapid format changes with minimum disruption.

How does the DH-L300 handle lid adhesion?

It combines vacuum suction technology to pick up lids and automated pressing mechanisms to guarantee solid attachment.

What are the routine maintenance requirements?

- Suction cups and lid-handling components should be cleaned regularly.

- Checking and calibrating sensors for accuracy.

- Lubrication of mechanical components as required.

- Regular software upgrades and calibration.

What are common troubleshooting issues and solutions?

- Lid misalignment? Check sensor calibration and make any adjustments to placement parameters.

- Suction failure? Ensure that the vacuum system is dust and debris-free.

- Does the machine stop unexpectedly? Check the control panel for any faults and, if required, reset the system.

Does DROID offer remote technical support?

Yes, we provide remote diagnostics and technical help for troubleshooting and software upgrades.

Can the DH-L300 be customized for different packaging sizes?

Yes, the machine may be adjusted for different lid and pack dimensions based on production requirements.

Does the machine integrate with existing production lines?

Yes, it is intended to work seamlessly with wet wipes manufacturing lines, such as automated conveyors, stacking, and palletizing equipment.

Is the DH-L300 compliant with industry standards?

Yes, it meets CE, ISO, and GMP requirements for hygiene and safety in wet wipes manufacturing.

What safety features does the machine include?

- Emergency stop buttons

- Protective covers and sensors

- Overload and error detection

Do you provide training for operators?

Yes, DROID provides on-site training and complete user manuals to guarantee a smooth operation.

How can I get spare parts for the DH-L300?

Spare parts are available straight from DROID’s service center, with quick international shipment.