PRODUCT DETAILS

PRODUCT SPECIFICATIONS

- Model: DH-FP

- Output product type: canister wipes

- Individual rolls Automation: semi-automatic rolled wet tissue converting machine

- Work flow: raw material loading —slitting—folding— punching—online wetting—auto counting—unwinding — finished product output — manual packaging

- Capacity speed: Max 100 rolls/min (Subject to material types)

- Suitable material: [35-80gsm] spun-lace nonwoven/ biodegradable material

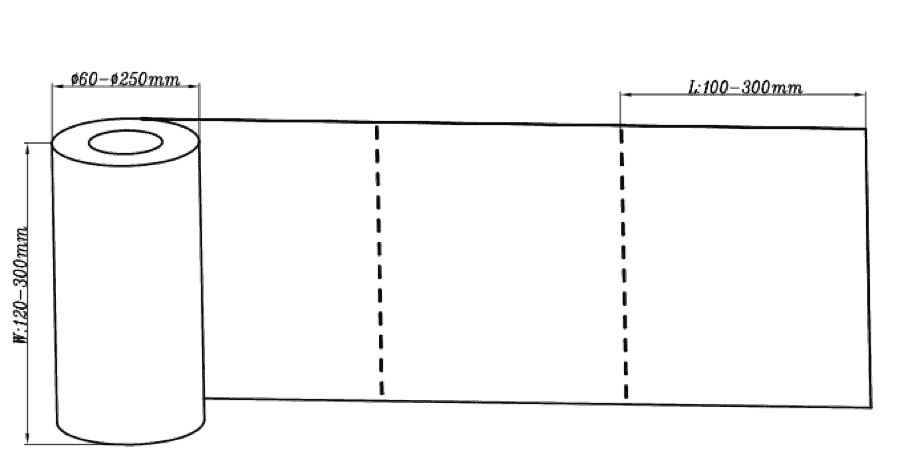

- Open tissue size:(100-300)x(120-300) mm

- Punching way: Spiral cutter

- Folding way: W,N,V C Types Wetting system: online-wetting

- Power: AC380V 50/60Hz | 8 kw

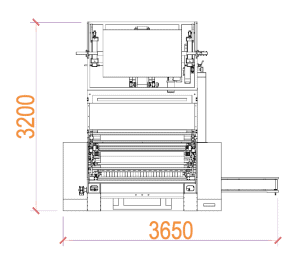

- Machine size: 3650×3200×1700 mm(L*W*H)

- Machine weight: 4500kg

PRODUCT FEATURES

- Converting capacity speed 150M/min; Max 100 rolls/min.

- Full Siemens servo driven PLC control system

- Nonwoven roll width 1500mm

- Automatic spliced roll removal

- Output tissue conveyor( 1.0meter )

PRODUCT DIMENSION

Do You Still Have Questions? We Can Assist You!

Our sales staff is here to help if you can’t find the answer you’re looking for. Please contact us if you have any questions about our products, prices, or anything else; we would be happy to assist you!

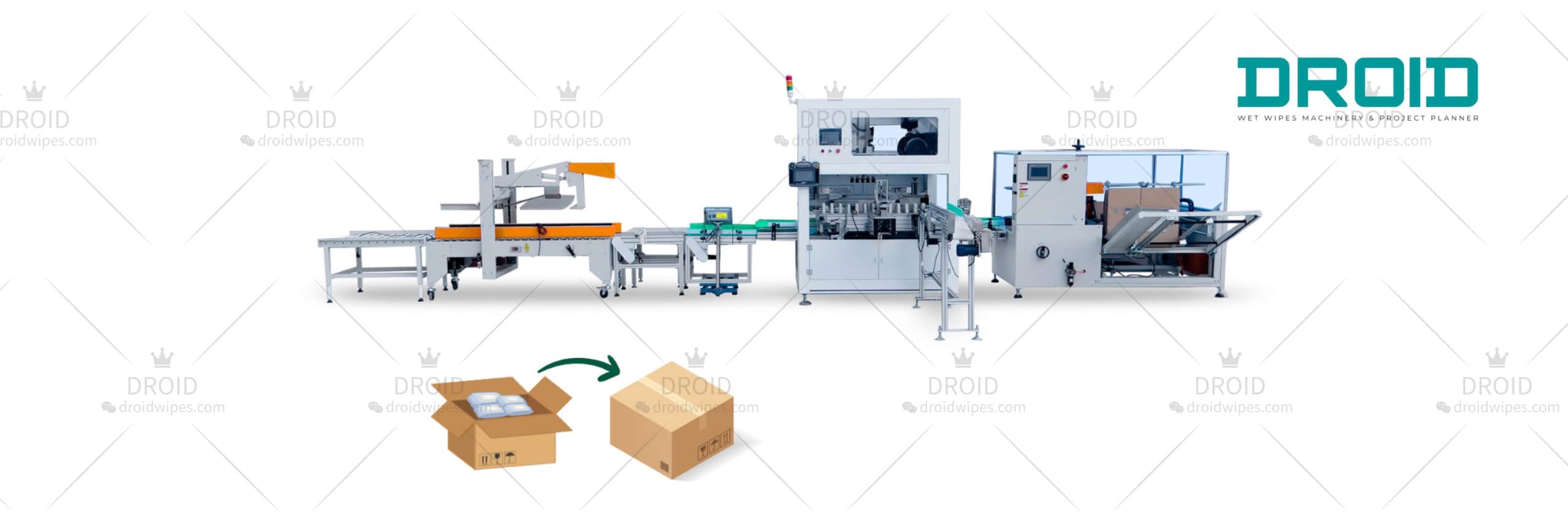

What is the DH-FP Canister Wet Wipes Converting Machine?

The DH-FP is an automated machine used to convert, fold, cut, and roll nonwoven fabric into canister-packed wet wipes.

What types of wet wipes can be produced with this machine?

It can make disinfection wipes, baby wipes, industrial wipes, and other canister-style wet wipes.

What materials are compatible with the machine?

The machine can handle nonwoven fabrics, including spunlace, spunbond, air-laid, and composite nonwoven materials.

How does the machine handle liquid dosing?

The DH-FP has a precise liquid dosing mechanism that ensures evenly saturated wipes.

Does the machine include an automatic roll-loading system?

It has an automated roll unwinding and splicing mechanism to ensure uninterrupted functioning.

How user-friendly is the DH-FP machine?

The machine has a touchscreen PLC control system that allows for simple operation and supports several languages.

What is the recommended maintenance schedule?

Regular maintenance involves daily cleaning, weekly lubrication, and inspections of cutting blades, rollers, and sensors.

What safety features are included?

Emergency stop buttons, safety guards, and an automated fault detection system keep operators safe.

Can the machine be customized for different canister sizes?

Yes, it can be customized for different canister sizes by adjusting specific variables.

Is it compatible with existing production lines?

The DH-FP is compatible with automated canister filling, sealing, and labeling systems.

Can it work with different liquid formulations?

Yes, it can handle diverse liquid viscosities, however, correct calibration is necessary.

What should I do if the machine stops unexpectedly?

Check the problem warnings on the PLC screen, look for material jams, and make sure the power supply is steady.

Who do I contact for technical support?

DROID offers 24-7 online help, remote troubleshooting, and on-site technical assistance.

Are spare parts readily available?

Yes, replacement parts may be obtained directly from DROID and sent globally.