PRODUCT DETAILS

PRODUCT SPECIFICATIONS

- Model: DH-6

- Output product type: 30-120 pulls/pack

- Semi-automation: 6 (5) lanes tissue converting machine

- Loading station: One station; one jumbo roll

- Work flow: Auto material loading → tissue slitting → Tissue folding→ online wetting → tissue cutting →stacking & counting →Tissues output in a pile→ manual packaging

- Capacity speed: 1200-1600pcs/min (Subject to material types)

- Suitable material: [35-80gsm] spun-lace nonwoven/ biodegradable material

- Open tissue size:(70-170)x(160-220) mm

- Folded tissue size:(70-170)x(80-110) mm

- Folding ways: “Z” non-pop up/ ”N” fold

- Wetting system: online-wetting

- Power: AC380V 50/60Hz | 5 kw

- Operation interface: Swing arm touch screen

- Machine size: 4500×2600×1950 mm(L*W*H)

- Machine weight: 2500kg

PRODUCT DIMENSION

VIDEO

Do You Still Have Questions? We Can Assist You!

Our sales staff is here to help if you can’t find the answer you’re looking for. Please contact us if you have any questions about our products, prices, or anything else; we would be happy to assist you!

What type of wet wipes does the DH-6 produce?

The DH-6 is designed to produce non-pop-up folded wet wipes (Z or N fold) in packs ranging from 30 to 120 pulls per pack. The wipes are output in stacked piles, ready for manual bagging.

Is the DH-6 fully automated?

No. The DH-6 is a semi-automatic machine that automates several core processes, including slitting, folding, online wetting, cutting, stacking, and counting. However, manual intervention is needed during the packaging stage, where an operator collects and packs the stacked tissues into bags.

What is the production speed of the DH-6?

The DH-6 runs at a capacity of 1200 to 1600 pieces per minute, depending on the material quality and wipe size. This high-speed performance makes it ideal for medium to large-scale production.

What materials are compatible with the DH-6?

Nonwoven spunlace and biodegradable materials between 35 and 80 gsm may be used with the machine. This includes sustainable and environmentally friendly wiping materials.

What are the size specifications of the wipes?

-

Open wipe size: (70–170) mm × (160–220) mm

-

Folded wipe size: (70–170) mm × (80–110) mm

These ranges provide great flexibility for different market needs.

What kind of folding styles are supported?

The DH-6 supports two main folding types:

-

Z fold (non-pop-up)

-

N fold

These folding styles are suitable for wet wipes used in home care, personal care, and other professional cleaning applications.

How does the wetting system work?

An online wetting mechanism on the DH-6 guarantees precise and reliable liquid application throughout the conversion process. Water or desired active components (such as sanitizers, baby lotion, pet-safe formulations, etc.) may be added to the liquid.

What is the machine’s footprint and weight?

-

Dimensions: 4500 mm (L) × 2600 mm (W) × 1950 mm (H)

-

Weight: Approximately 2500 kg

Ensure that your production facility has adequate space and flooring capacity for the installation.

How many lanes does the DH-6 operate with?

The machine features 6 converting lanes, with 5 lanes active under semi-automated operation, optimizing production throughput while ensuring ease of use.

What is the power requirement?

The DH-6 operates on AC 380V, at a frequency of 50/60Hz, with a power consumption of 5 kW, making it an energy-efficient option for its category.

Is the machine easy to operate?

Yes, the DH-6 features a touchscreen operating interface with a swing arm, making it easy for the operator to set parameters, monitor machine performance, and make adjustments.

What is the typical use case for the DH-6?

When fully automated bagging is unnecessary, the DH-6 is an ideal choice for wet wipe manufacturers looking for an affordable, versatile, and compact solution to produce various types of wipes.

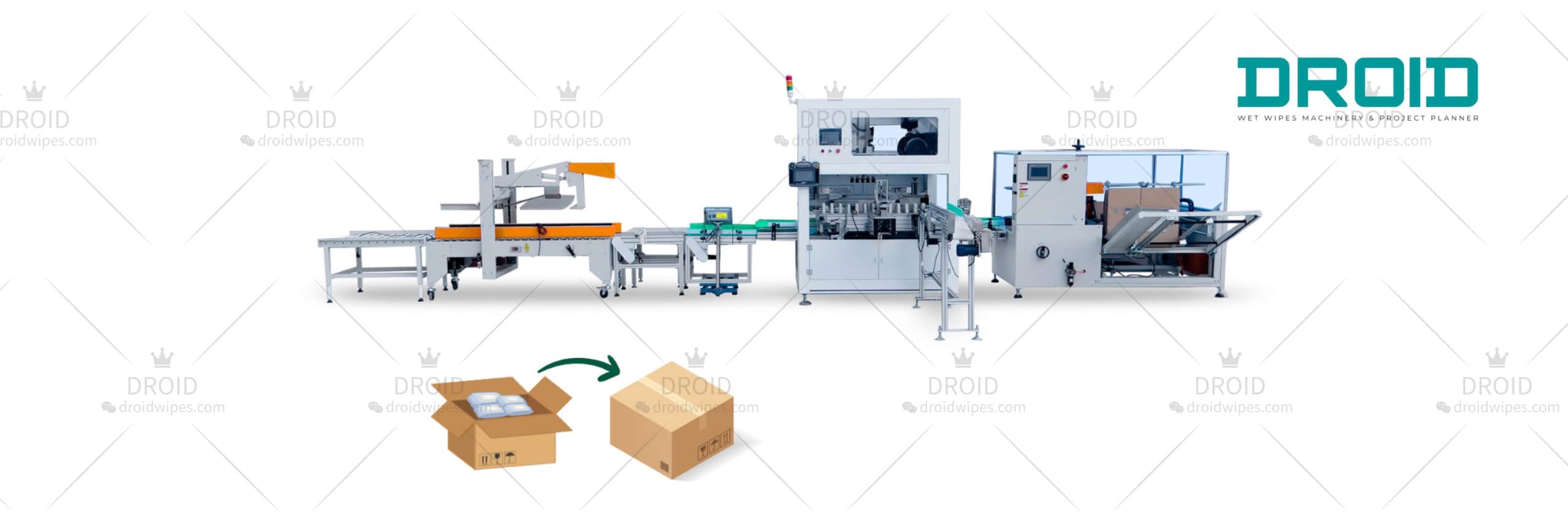

Can the DH-6 integrate with other machines like automatic packers or palletizers?

While the DH-6 is a standalone converting unit, it can be paired with automated bagging machines or robotic palletizers in later production stages to improve efficiency and minimize manual labor.

What kind of maintenance does the DH-6 require?

Sharpening or replacing blades, cleaning wetting nozzles, lubricating moving components, and, if necessary, updating software regularly are all examples of routine maintenance. The machine’s user handbook has comprehensive maintenance instructions.

Is training and after-sales support available?

Of course. DROID provides comprehensive user manuals, on-site or remote operator training, and round-the-clock technical assistance. Wear components and spare parts are easily accessible upon request.