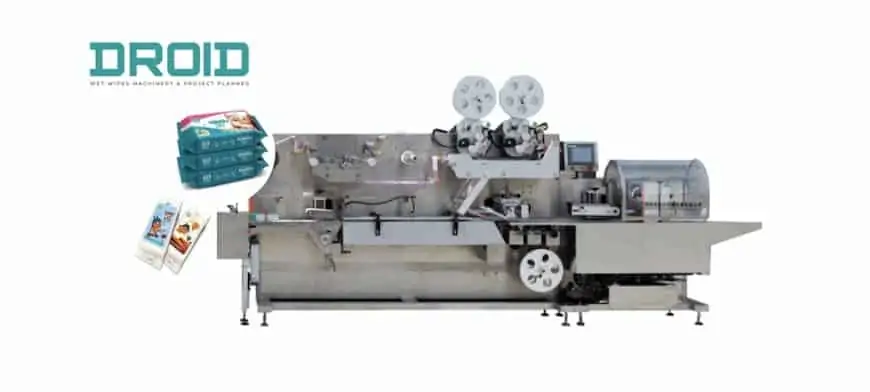

PRODUCT DETAILS

Features

- Model: DH-200

- Output product type: Bed bath towel; Adult washcloth; cleaning wipes; make-up removal wipes

- Converting type: 5-30 pulls/pack

- Semi-automation: tissue converting machine

- Work flow: Auto material loading → Tissue folding→ online wetting → tissue cutting →stacking & counting →Tissues output in a pile→ manual packaging Capacity speed: 350-600pcs/min (Subject to material types) Suitable material: [35-80gsm] spun-lace nonwoven/ biodegradable material

- Open tissue size: 200(Customized)x (100-400) mm

- Folded tissue size:100(Customized)x (50-200) mm

- Folding ways: “Z” + cross fold

- Wetting system: online-wetting Power: AC380V 50/60Hz | 3.8 kw

- Operation interface: touch screen

- Machine size: 3450×1150×1670 mm(L*W*H)

- Machine weight: 1100kg

Machine Parameters

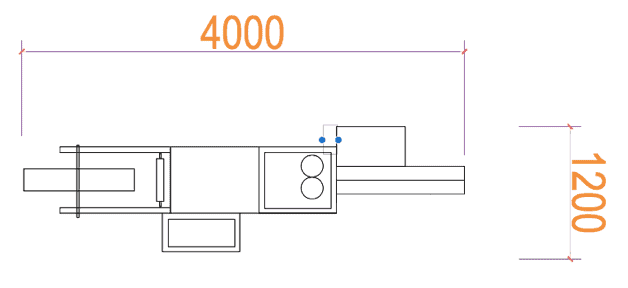

Machine Layout

Do You Still Have Questions? We Can Assist You!

Our sales staff is here to help if you can’t find the answer you’re looking for. Please contact us if you have any questions about our products, prices, or anything else; we would be happy to assist you!

What is the UT-FL1 wet wipes converting machine used for?

The UT-FL1 is intended to produce wet wipes in packets of 5 to 40 wipes. It can fold, cut, moisten, stack, and carry personal care items, baby wipes, and domestic cleaning supplies.

What is the production capacity of the UT-FL1 machine?

The UT-FL1 can generate 100-120 packs every minute, depending on the number of wipes in each pack and the material used.

What is the range of wipe sizes that the UT-FL1 can process?

It accommodates a broad variety of unfolded wipe sizes, from 150mm x 180mm to 300mm x 300mm, but may be tailored to user specifications.

What types of nonwoven materials are compatible with this machine?

The UT-FL1 is suitable with spunlace, spunbond, air-laid, and biodegradable nonwovens weighing 30-80 gsm.

Can the machine handle different liquid formulations?

Yes, the UT-FL1 comes with a precise liquid dosing system that works with water-based liquids, alcohol-based solutions, lotions, and disinfectants.

What are the main features of the UT-FL1 machine?

- High-speed, steady performance

- Adjustable wipe count (5-40 wipes per pack)

- Servo-controlled cutting and stacking

- User-friendly HMI touch screen

- Automatic material feeding and tension control

- Integrated wetting system with precise dosage

How easy is it to change wipe count or pack format?

The machine is intended for rapid and simple format changes. Within 15-30 minutes, operators may alter the wipe count and pack configurations using the HMI.

What kind of packaging system can the UT-FL1 integrate with?

It works smoothly with automated wet wipes flow wrappers, multipack baggers, and robotic case packers.

Is operator training provided?

Yes, DROID will give complete operator training, both on-site and remotely, to assure the UT-FL1’s safe and efficient operation.

What are the power and utility requirements?

- Standard power requirements: 380V, 50Hz, 3-phase (customizable).

- Compressed air: 0.6 to 0.8 MPa. Water connection required for the wetting system (if relevant).

What are the key safety features?

- Emergency stop buttons

- Safety light curtains (optional)

- Protective covers with interlocks

- Overload protection and alarms

How often does the UT-FL1 require maintenance?

Routine maintenance is advised every 500 production hours, and preventative maintenance plans are included in the handbook.

Does the machine come with a warranty?

Yes, the UT-FL1 has a 12-month guarantee that covers manufacturing defects and important components.

Can the machine be customized?

Yes, we provide customization for folding styles, wipe sizes, liquid dosing, and interaction with downstream packing operations.

What certifications does the UT-FL1 have?

The machine complies with CE, ISO9001, and other industry-specific requirements.

Is remote technical support available?

Yes, DROID can provide 24/7 remote technical help and may deploy service experts as needed.

Who are the typical users of this machine?

The UT-FL1 is suitable for wet wipes manufacturers, contract packagers, personal care companies, and hygiene product producers that want flexible production for small-to-medium pack sizes.