PRODUCT DETAILS

PRODUCT SPECIFICATIONS

- Model: DH-12F

- Output product type: 30-120 pulls/pack

- Loading station: 12 stations/ 12 Individual rolls

- Full automatic: 12 (10) lanes tissue converting machine + one flow pack packaging machine (No Human Touch)

- Work flow: Auto material loading → tissue slitting → Tissue folding→ online wetting → tissue cutting →stacking & counting →auto tissue delivery to packaging machine → punching →labeling →sealing →finished product output

- Capacity: Converting speed: 2800-3500pcs/min | Packaging speed: 30-40 packs/min (Subject to material types)

- Control system:PLC + Full servo driven system

- Suitable material: [35-80gsm] spun-lace nonwoven/ biodegradable material

- Open tissue size:(70-170)x(160-220) mm

- Folded tissue size:(70-170)x(80-110) mm

- Packing size:(150-300)x(50-120)x(10-100)mm

- Folding ways: “Z” Pop-up/ non-pop up/ ”N” fold

- Wetting system: online-wetting

- Power: AC380V 50/60Hz | 11 kw

- Operation interface: Swing arm touch screen

- Machine size: 13000×2600×1950 mm(L*W*H)

- Machine weight: 6150kg

PRODUCT DIMENSION

VIDEO

Do You Still Have Questions? We Can Assist You!

Our sales staff is here to help if you can’t find the answer you’re looking for. Please contact us if you have any questions about our products, prices, or anything else; we would be happy to assist you!

What is the DH-12F and what makes it different from other wet wipes machines?

The DH-12F is a fully automatic, high-efficiency machine designed for converting wet wipes and packaging them in flow packs. It is capable of producing packs with 30 to 120 pulls each. What distinguishes this machine is its no-human-touch production line, which includes 12 individual roll loading stations and multi-lane converting. It seamlessly integrates with a flow pack machine, providing exceptional levels of automation and hygiene.

What is the production capacity of the DH-12F?

-

Converting speed: 2,800–3,500 pcs/min

-

Packaging speed: 30–40 packs/min

Actual output varies based on the material type, wipe count per pack, and folding configuration.

What materials are suitable for use with the DH-12F?

It supports:

-

Spunlace nonwoven (35–80gsm)

-

Biodegradable materials

This makes it ideal for eco-friendly wipe production or traditional hygiene and cleaning products.

What folding types does the DH-12F support?

The machine can produce:

-

“Z” fold (pop-up or non-pop-up)

-

“N” fold

This flexibility allows you to cater to various markets like baby wipes, household wipes, and personal care wipes.

What is the size range of wipes the machine can handle?

- Open tissue size: 70–170mm (W) × 160–220mm (L)

-

Folded tissue size: 70–170mm (W) × 80–110mm (L)

-

Pack size: 150–300mm (L) × 50–120mm (W) × 10–100mm (H)

What is the full working process of the DH-12F?

-

Auto Material Loading

-

Tissue Slitting

-

Tissue Folding

-

Online Wetting

-

Cutting

-

Stacking & Counting

-

Auto Delivery to Flow Pack Machine

-

Film Punching (for lid opening)

-

Labeling

-

Sealing

-

Finished Pack Output

All steps are fully automatic and require no human contact, ensuring product safety and consistency.

What kind of control system does the DH-12F use?

It features a PLC and a fully servo-driven system with a swing-arm touch screen, providing high accuracy, real-time adjustments, a user-friendly interface, and stable performance with fewer mechanical parts.

Is the wetting system precise and adjustable

Yes, the online wetting system provides:

-

Uniform liquid distribution

-

Adjustable dosing

-

Minimal waste.

It is ideal for wet wipes that contain baby lotion, disinfectant solutions, or skincare liquids.

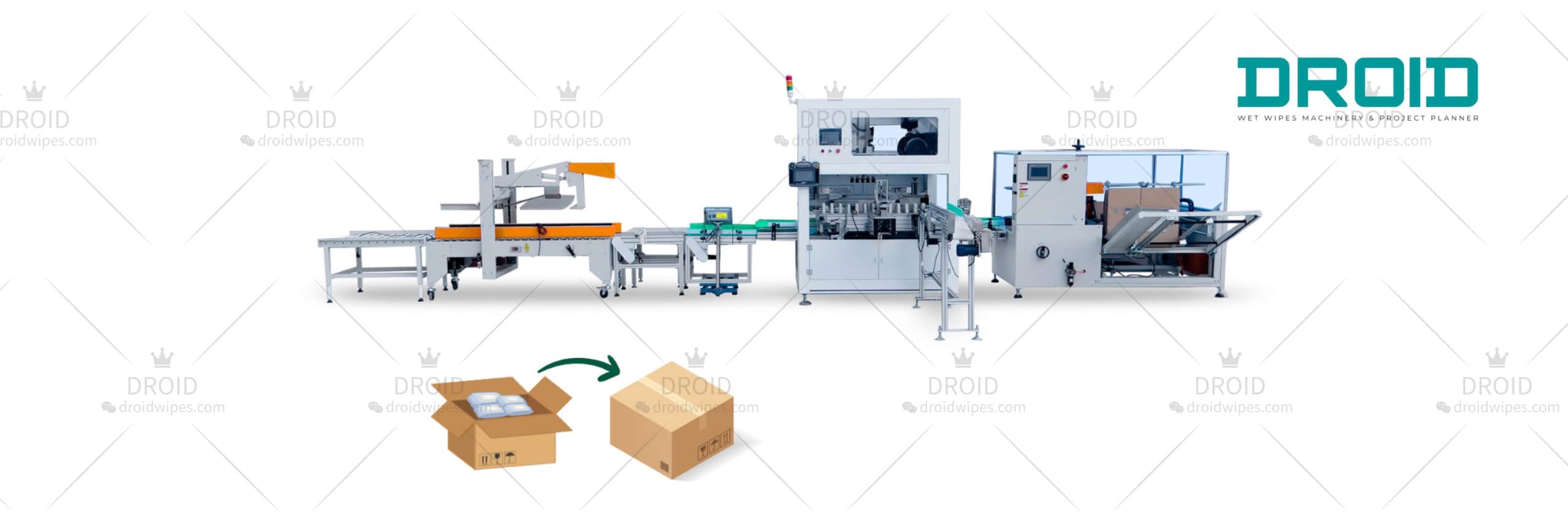

Can the DH-12F integrate with other packaging systems or labeling machines?

Yes, it comes with a built-in flow pack packaging machine and can include:

-

Film punching unit

-

Label applicator

-

Custom end-of-line systems (like palletizers)

What are the power and air requirements?

-

Power: AC380V, 50/60Hz, 11kW

-

Compressed Air: Recommended 0.6–0.8 MPa

How big is the machine and what space is needed for setup?

-

Machine size: 13,000mm × 2,600mm × 1,950mm (L×W×H)

-

Weight: 6,150 kg

For optimal performance, it is recommended to have a clean, dust-free environment that is well-ventilated.

What kind of maintenance does the DH-12F require?

Regular maintenance includes:

-

Blade checks and replacements

-

Sensor and servo calibration

-

Lubrication of moving parts

-

Filter and nozzle cleaning for the wetting system

Preventive maintenance every 2-3 months extends machine life.

What kind of technical support and training is provided?

DROID offers on-site installation and commissioning, operator training, remote technical support, and warranty coverage as well as spare parts availability.

What are the hygiene advantages of a “No Human Touch” system?

The DH-12F automation system minimizes contamination risks, enhances product consistency, and ensures compliance with GMP and FDA standards for hygiene-critical markets such as baby care and disinfectant wipes.

Can the machine be customized for special pack sizes or folding styles?

Yes. The DH-12F can be customized to meet:

-

Specific branding requirements

-

Unique tissue sizes or materials

-

Local packaging regulations