PRODUCT DETAILS

PRODUCT SPECIFICATIONS

- Model: DH-12

- Output product type: 30-120 pulls/pack

- Semi-automation: 12 (10) lanes tissue converting machine

- Loading station: Two stations; two jumbo rolls

- Work flow: Auto material loading → tissue slitting → Tissue folding→ online wetting → tissue cutting →stacking & counting →Tissues output in a pile→ manual packaging

- Capacity speed: 2800-3500pcs/min (Subject to material types)

- Suitable material: [35-80gsm] spun-lace nonwoven/ biodegradable material

- Open tissue size:(70-170)x(160-220) mm

- Folded tissue size:(70-170)x(80-110) mm

- Folding ways: “Z” non-pop up/ ”N” fold

- Wetting system: online-wetting

- Power: AC380V 50/60Hz | 5 kw

- Operation interface: Swing arm touch screen

- Machine size: 6100×2600×1950 mm(L*W*H)

- Machine weight: 3300kg

PRODUCT DIMENSION

VIDEO

Do You Still Have Questions? We Can Assist You!

Our sales staff is here to help if you can’t find the answer you’re looking for. Please contact us if you have any questions about our products, prices, or anything else; we would be happy to assist you!

What is the DH-12 wet wipes machine used for?

The DH-12 is a semi-automatic machine designed for converting raw materials into soft packs of wet wipes. It produces packs containing between 30 to 120 wipes each. The machine handles the entire conversion process, resulting in stacked wipes that are ready for manual packaging.

What is the production capacity of the DH-12?

The DH-12 can produce between 2,800 and 3,500 pieces per minute, depending on the type of material and the complexity of folding.

What type of materials can this machine process?

It works well with nonwoven spun-lace and biodegradable materials that weigh between 35 and 80 grams per square meter.

What are the folded and unfolded tissue sizes it can handle?

-

Open tissue size: 70–170 mm (width) x 160–220 mm (length)

-

Folded tissue size: 70–170 mm (width) x 80–110 mm (length)

What types of folding styles does the DH-12 support?

The machine supports:

-

“Z” fold (non-pop-up)

-

“N” fold

These designs prioritize a user-friendly experience, which is often found in the packaging of consumer wet wipes.

Is the wetting system built into the machine?

The online wetting system applies liquid directly during the converting process, ensuring consistent moisture levels across all wipes.

Is the DH-12 fully automated?

The DH-12 is a semi-automatic machine. Although the converting process is automated, including loading, slitting, folding, wetting, cutting, and stacking, the final packaging is done manually.

How many jumbo rolls can it load at once?

The machine is equipped with two loading stations, allowing it to handle two jumbo rolls at the same time, improving operational efficiency and minimizing downtime.

How many lanes does it operate with?

The DH-12 has 12 converting lanes (can be adjusted to 10 depending on the production setup), allowing for the simultaneous processing of multiple wipe stacks.

What kind of businesses is this machine suitable for?

The DH-12 is perfect for medium to large wet wipes manufacturers who need high-speed converting while managing manual packaging operations. It’s also ideal for companies providing custom private-label wet wipes and eco-friendly biodegradable products.

What are the power requirements?

The machine operates on AC power at 380V and 50/60Hz, and it has a power consumption of 5 kW.

What certifications does the DH-12 comply with?

The DH-12 wet wipes converting machine satisfies industrial safety and quality requirements such as ISO9001 and CE.

Is on-site installation and training provided?

Yes, as part of our after-sales service, we provide on-site installation, commissioning, and operator training.

What is the size and weight of the DH-12 machine?

-

Machine dimensions: 6100 × 2600 × 1950 mm (L×W×H)

-

Weight: 3300 kg

What type of user interface does the machine use?

The machine is controlled via a swing arm touch screen, enabling intuitive adjustments of settings and real-time production monitoring.

Can this machine handle alcohol-based or disinfectant solutions?

Yes, the DH-12 can accommodate alcohol-based or disinfectant wetting liquids. However, it is essential to confirm the compatibility of the wetting system and materials to ensure safety and effectiveness.

Can the machine be customized?

Customizations can be made based on customer requirements, including:

-

Additional lanes or folding styles

-

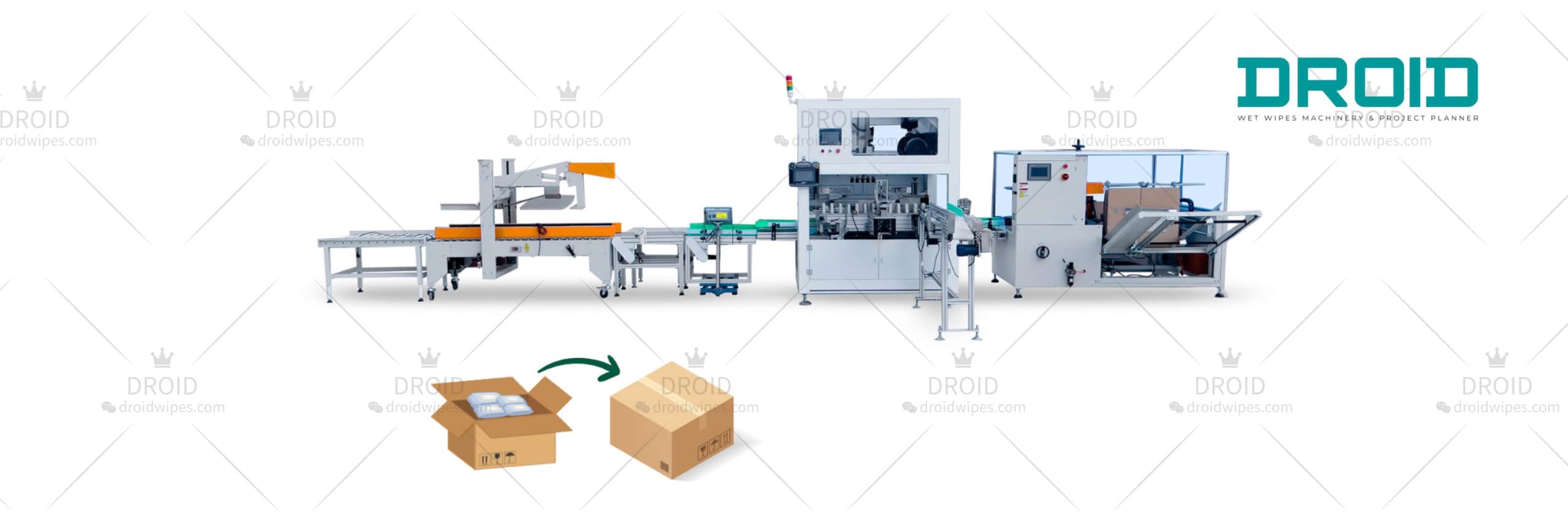

Integration with automatic bagging or sealing machines

-

Upgrades for processing biodegradable materials