120pcs/pack

72pcs/pack

80pcs/pack

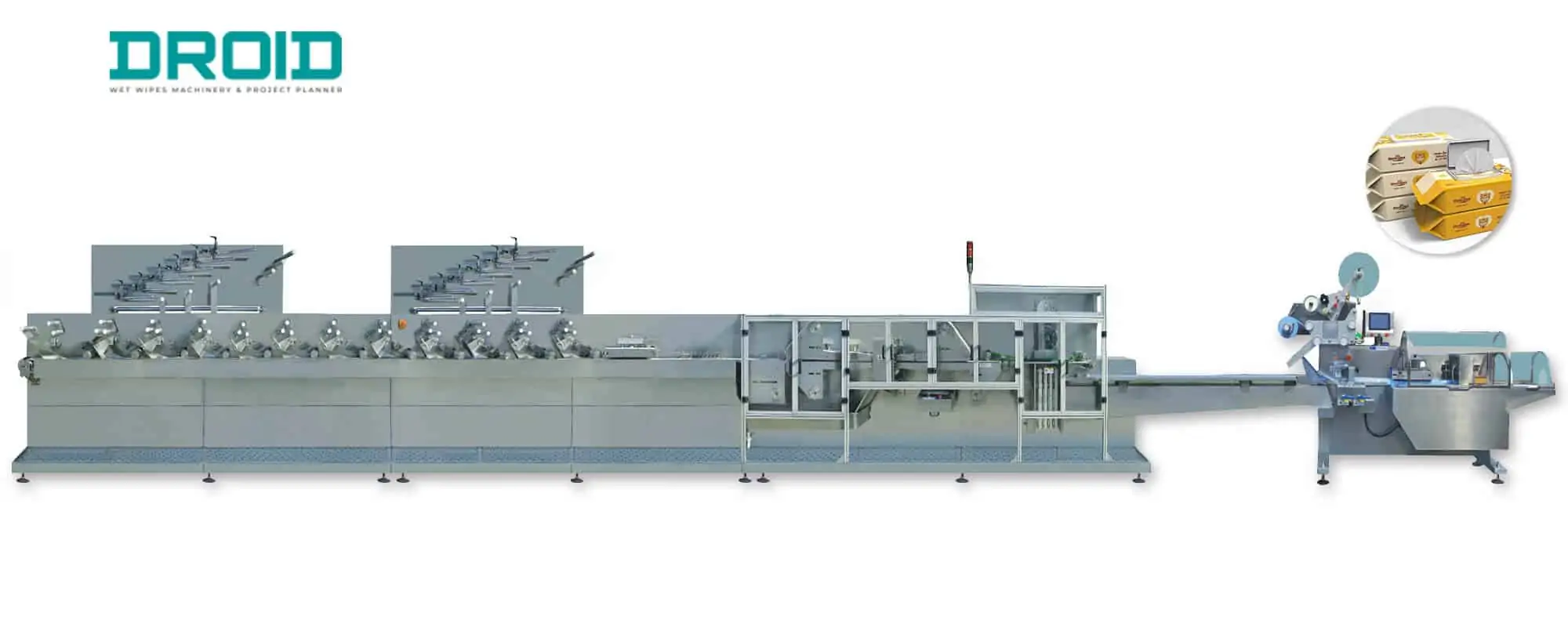

UT-BL10(12) Flow Pack Wet Wipes Machine Running Demo

PRODUCT DETAILS

Features

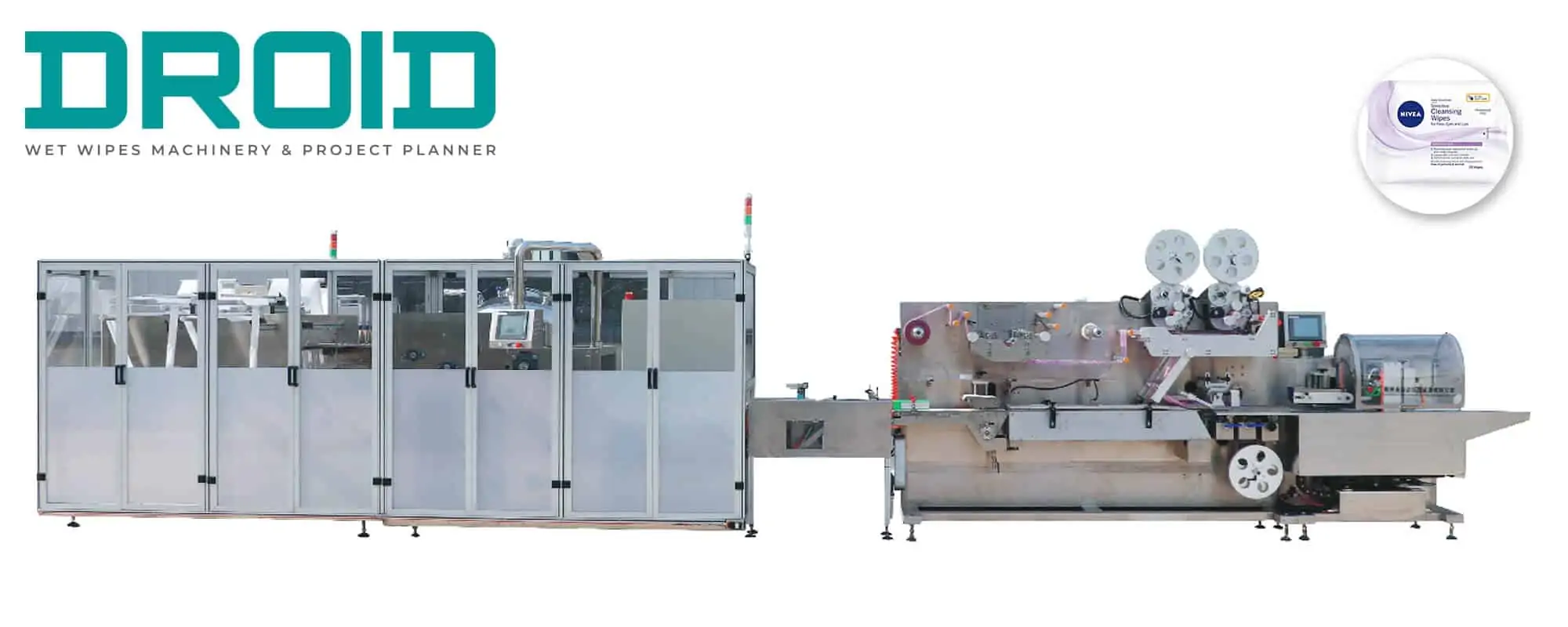

UT-BL10(12) Automated Wet wipes production line is comprised of a wet tissue folding machine and a Flow wrap wet wipes packaging machine.

It is a basic & entry level model that comes with capacity speed of 4500 pcs/min and two jumbo mother rolls on its loading stations.

This machine is capable of producing flat pack wet wipes in wide range of dimensions in terms of both width and length.

It is designed to make a vast variety of wet wipes in a pack of 20-120 sheets such as baby wipes, disinfecting wipes, sanitizing wet wipes, household cleaning wipes, personal hygiene wipes, adult wipes, pet wipes, industrial wipes, biodegradable wet wipes and flushable wet toilet papers.

- Output Product: all types of wet tissue (20-120 pcs/pack)

- Folding types: Z/N; Z Pop up

- Full automated with no need for human interference throughout the production process

- Machine design in compliance with FDA GMP hygiene & safety standard

- Full Servo driven and CPU control system

- Precise wetting system with deviation of+3g per pack

- Tissue & Packing length and width size changed by servo system, no mechanical adjustment needed

- All conveyor belts are food-grade, anti-bacterial for hygienic product transfer

- 304L Stainless steel is applied to the cover of machine and main spare parts in contact with lotion and fabric

- Easy and quick change over between different formats

- Visual & audible warning systems

- User-friendly HMI with touch screen

- Machine stops automatically when machine breaks down

- Structure: (1) raw material loading station, (2) Tension control device, (3) tissue folding device, (4) Precise online wetting system, (5) automatic stacking device, (6) auto die cutting unit, (7) auto labeling unit,(8) auto film change-over system(9) Auto-Electrical eye tracking (10) Auto air-rejection unit,(11) servo driven sealing unit for finished products.

Work Flow:

Automated Nonwoven loading→ tension control → tissue slitting →tissue folding→ Precise online wetting→ tissue cutting→ tissue stacking & counting →tissue wait-in-line→ tissue delivery to packaging machine→ bag forming →die cutting→ labeling→ gusseting →auto air → sealing→ finished product output

Output Product:

- Personal care wipes

Baby wipes

Adult wipes

Bed bath wet towel

Disinfectant wipes

Antibacterial wipes

Medicare wipes

Hand sanitizing wet wipes

Beauty wipes

Hygiene Wet Wipes

Feminine wipes

Pets wipes

- Household wipes

Home care wipes

Household cleaning wipes

Home disinfecting wipes

Floor cleaning wipes

Kitchen cleaning Wipes

Bathroom cleaning wipes

Moist Toilet wipes

Automotive car cleaning wipes

Flushable wipes

Flushable moist toilet wipes

- Commercial/ industrial wipes

Wipes for general purpose

Speciality Wipes

Machine cleaning wipes

Healthcare wipes

Machine Parameters

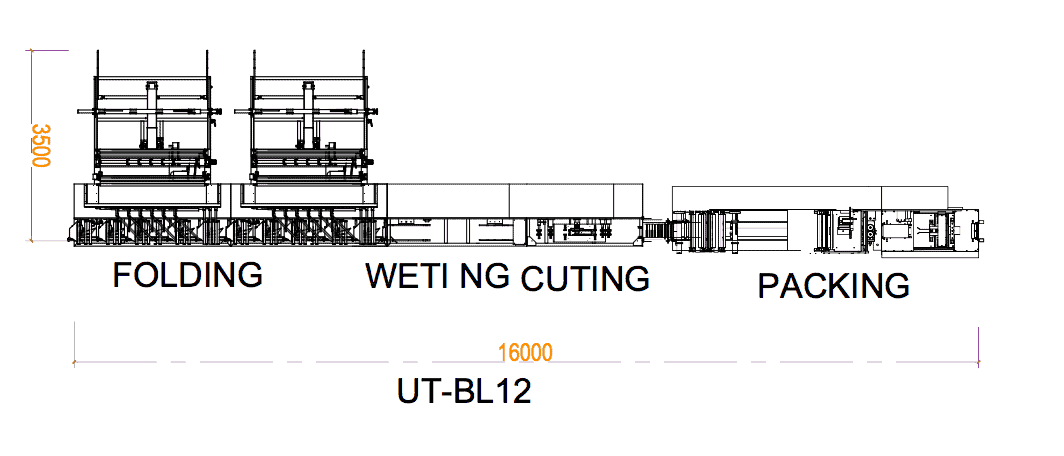

- Model: UT-BL 10(12)

- Output product type: 20-120wipes/pack

- Loading station: 2 jumbo rolls raw material

- Non-woven Change-over system: Labor work/ Non-automatic

- Full automatic: tissue converting machine + flow pack packaging machine (No Human Touch)

- Work flow: Auto material loading → tissue slitting → Tissue folding→ online wetting → tissue cutting →stacking & counting →auto tissue delivery to packaging machine → punching →labeling →sealing →finished product output

- Capacity: Converting speed: 4500pcs/min | Packaging speed: 50-80 packs/min (Subject to material types)

- Control system:PLC+ Full servo driven system

- Suitable material: [35-80gsm] spun-lace nonwoven/ biodegradable material

- Open tissue size:(100-270)x(140-210) mm

- Folded tissue size:(100-270)x(80-110) mm

- Packing size:(100-350)x(80-110)x(5-130)mm

- Folding ways: “Z”pop up/non-pop up/ ”N” fold

- Wetting system: Quantitative online-wetting

- Power: AC380V 50/60Hz | 18kw

- Operation interface: Swing arm touch screen

- Machine size: 16000×3500×2100 mm(L*W*H)

- Machine weight: 8000kg

Machine Layout

Do You Still Have Questions? We Can Assist You!

Our sales staff is here to help if you can’t find the answer you’re looking for. Please contact us if you have any questions about our products, prices, or anything else; we would be happy to assist you!

What types of wet wipes can the UT-BL10/12 produce?

The machine is highly versatile and can generate various wipes, such as infant wipes, adult wipes, household wipes, personal hygiene wipes, disinfecting wipes, flushable commode wipes, and more, with a bundle size of 20 to 120 sheets.

What are the folding options available?

It supports “Z” fold, “Z” pop-up, and “N” fold formats.

Is the UT-BL10/12 a fully automatic production line?

Yes. This machine integrates both converting and packaging sections, thereby automating the entire process from the loading of nonwovens to the final output of sealed products without human intervention.

What is the production capacity?

-

Converting speed: up to 4,500 pcs/min

-

Packaging speed: 50–80 packs/min (depending on material type and pack size)

What wipes and packaging sizes are supported?

-

Open tissue size: 100–270 mm (W) × 140–210 mm (L)

-

Folded tissue size: 100–270 mm (W) × 80–110 mm (L)

-

Packing size: 100–350 mm (L) × 80–110 mm (W) × 5–130 mm (H)

How easy is it to switch between different wipe sizes or formats?

Mechanical modifications are not necessary for the size and format transition, which is servo-controlled, thereby guaranteeing a rapid and effortless format change.

How accurate is the wetting system?

It utilizes a precision online watering system with a deviation of only ±3g per container.

Is the machine safe and hygienic for producing cosmetic or medical wipes?

Yes. It is engineered to adhere to the hygiene and safety standards of the FDA GMP, utilizing 304L stainless steel for all components that come into contact with liquid or fabric. All conveyors are antibacterial and of food-grade quality.

What type of nonwoven materials can it handle?

The UT-BL10/12 is compatible with spun-lace nonwoven materials ranging from 35–80 gsm, including biodegradable options.

Is the jumbo roll changeover automatic?

No. The manual process of changing the nonwoven material roll is applied to this entry-level model.

What kind of control system does it use?

The machine is equipped with a complete servo system and a PLC, which provides exceptional flexibility, reliability, and precision.

Is it easy for operators to control the machine?

Indeed. It is equipped with a swing-arm touch screen interface (HMI) that is both user-friendly and optimized for optimal operation.

What happens if the machine detects an error?

In the event of a malfunction, the system will autonomously cease operation to ensure the safety of the operator and the quality of the product. Visual and audible alarms are also included.

Is technical training and installation support provided?

Certainly, DROID offers comprehensive installation guidance, operator training, and post-sales technical support to guarantee seamless operation.

Is this machine suitable for startups or only large factories?

The UT-BL10/12 is a full-automation model that is suitable for both larger factories and growing manufacturers who require flexible, high-efficiency production. It is designed as an entry-level model.

Can it be used for both OEM and branded production?

Yes. It is the optimal choice for contract packaging services, in-house branded wiping, or OEM/private label manufacturing due to its efficiency, flexibility, and high-quality output.

What makes UT-BL10/12 stand out from other machines in the market?

-

Compact footprint with full automation

-

High precision wetting and folding

-

No manual adjustments for size changes

-

FDA-GMP compliant design

-

Cost-effective option for scalable production