120pcs/pack

72pcs/pack

80pcs/pack

Applications

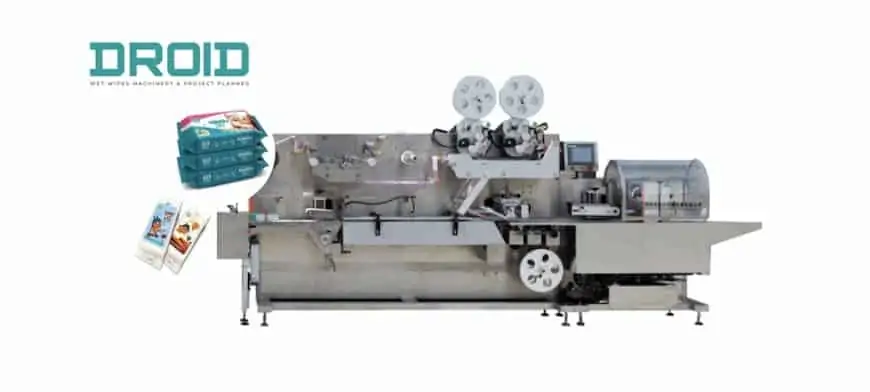

UT-BM16(20) Wet Wipes Machine is Suitable to make BIG POUCH wet wipes in a pack of 20-120pcs.

UT-BM16(20) Wet Wipes Machine Features

Model UT-BM16(20) automated flow pack wet wipes machine is Droid’s Flagship that could WOW you with its

- High performance

- Attention to details

- Low Lifetime Cost of Ownership

MITSUBISHI (Japan)

SICK(Germany)

SKF (Swedish)

SCHNEIDER(France)

UT-BM16(20) Wet Wipes Machine Parameters

| Model | UT-BM 16 (20) |

| Output product type | 20-120 wipes/pack |

| Tissue Folding ways | “Z”pop up/non-pop up/ ”N” fold |

| Capacity | Converting speed: 7200-9000 pcs/min | Packaging speed: 80-100 packs/min |

| Loading station | 16 (20)stations/ Two independent rolls on one core shaft |

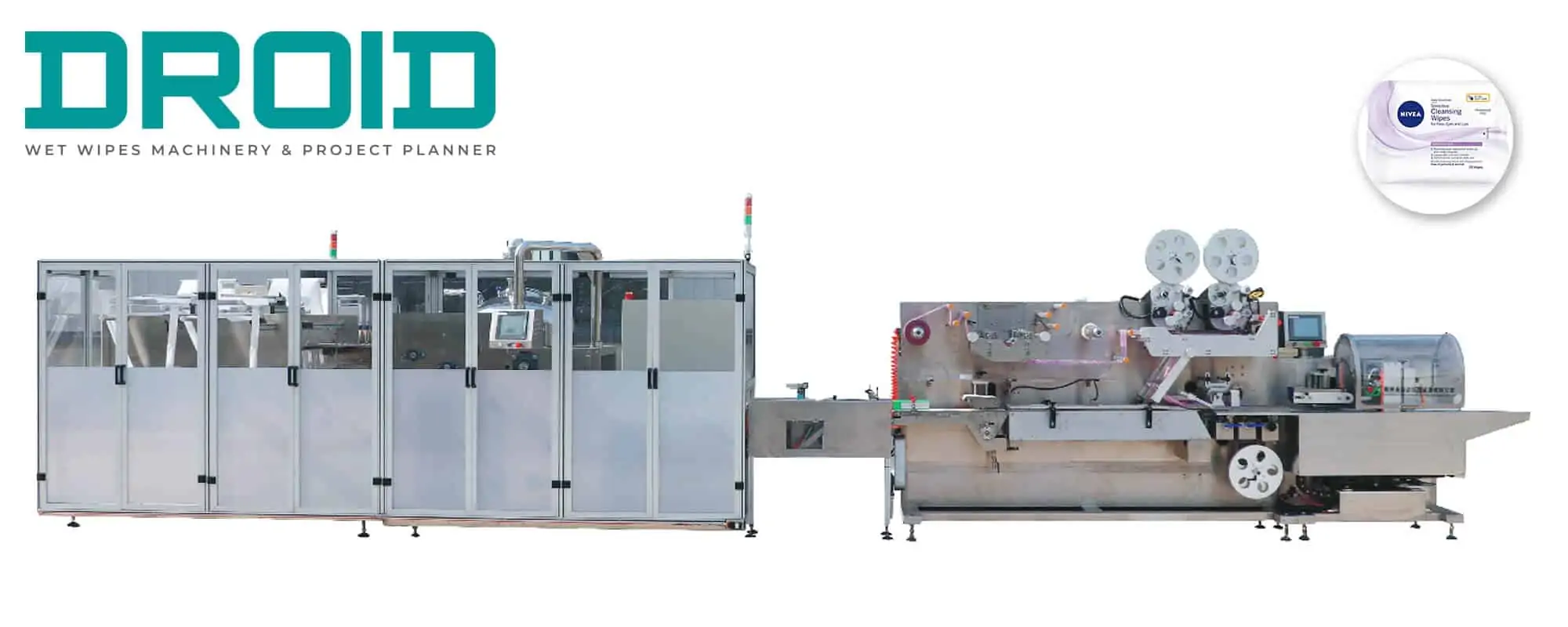

| Full automatic structure | 16(20) lanes tissue converting machine + one flow pack packaging machine (No Human Touch) |

| Automatic Non-stop raw material change-over system | √ |

| Control system | CPU + Full servo driven system |

| Suitable material | [30-100gsm] spun-lace nonwoven/ biodegradable material |

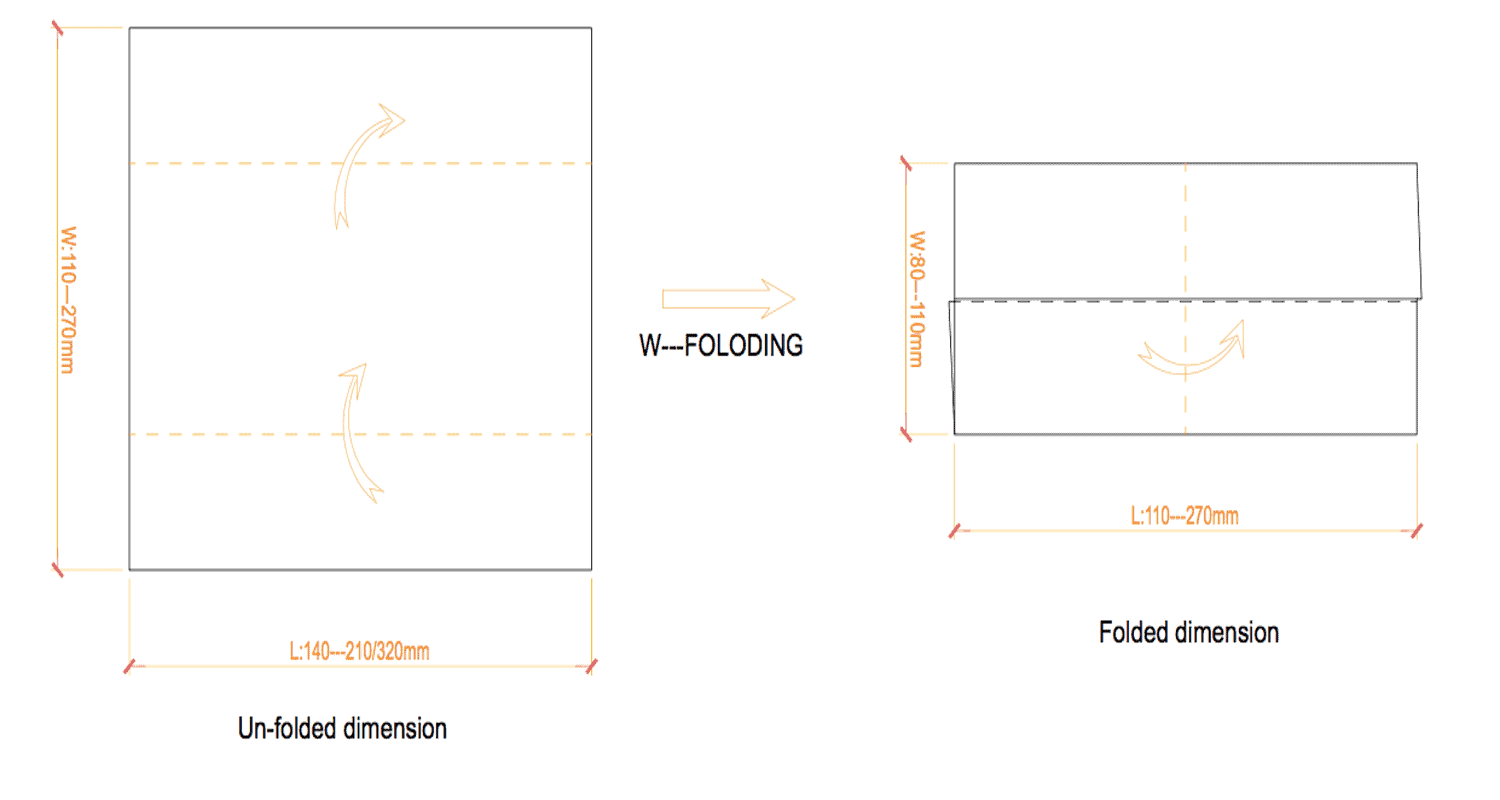

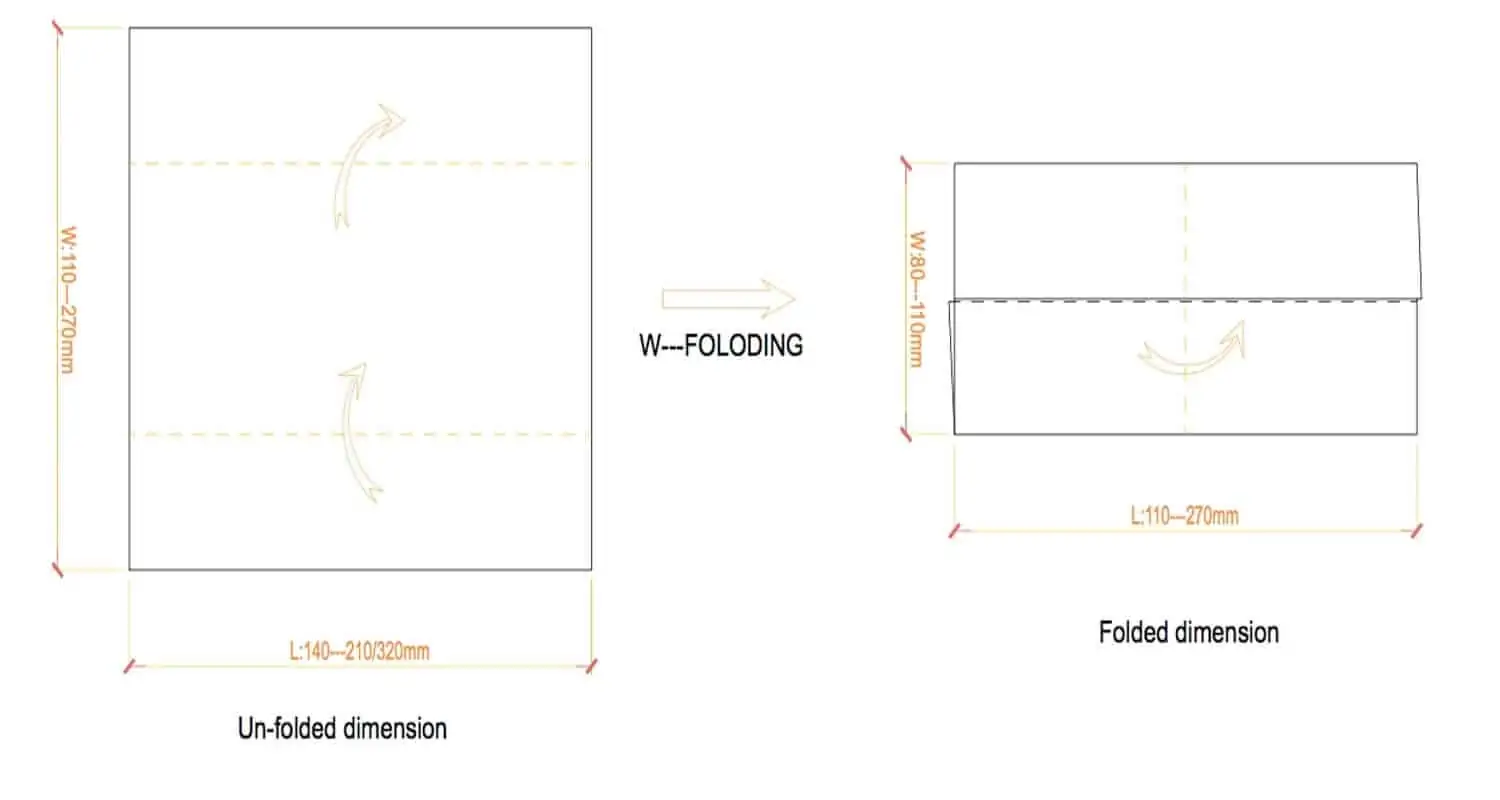

| Open tissue size | (100-270)x(140-210) mm (LXW) |

| Folded tissue size | (100-270)x(80-115) mm ( LXW) |

| Packing size | (100-350)x(80-110)x(5-120)mm (LXWXH) |

| Wetting system | Precise online-wetting |

| Power | AC380V 50/60Hz | 20kw |

| Operation interface | Swing arm touch screen |

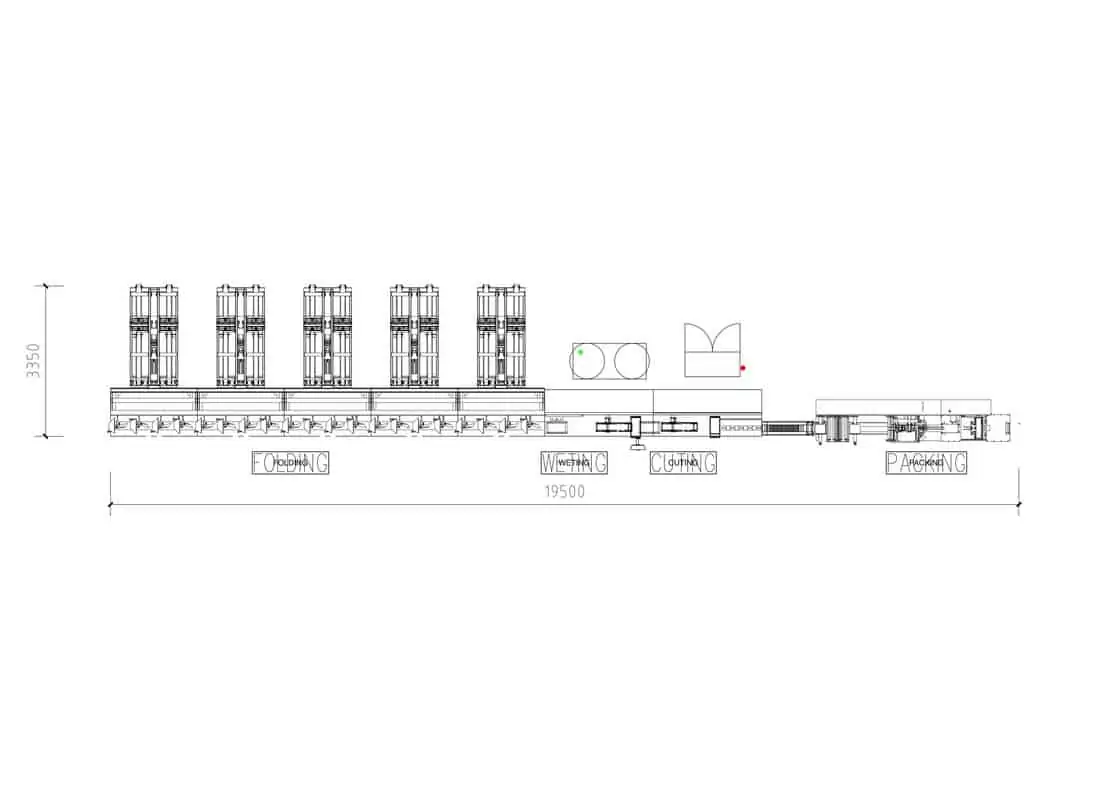

| Machine size | 19500×3350×2100 mm(L*W*H) |

| Machine weight | 13,000kg |

UT-BM16(20) Wet Wipes Machine Layout

All Types of Wet Wipes Made On This Machine

- Personal care wipes

Baby wipes

Adult wipes

Bed bath wet towel

Disinfectant wipes

Antibacterial wipes

Medicare wipes

Hand sanitizing wet wipes

Beauty wipes

Hygiene Wet Wipes

Feminine wipes

Pets wipes

Biodegradable wet wipes

- Household wipes

Home care wipes

Household cleaning wipes

Home disinfecting wipes

Floor cleaning wipes

Kitchen cleaning Wipes

Bathroom cleaning wipes

Moist Toilet wipes

Automotive car cleaning wipes

Flushable wipes

Flushable moist toilet wipes

- Commercial/ industrial wipes

Wipes for general purpose

Speciality Wipes

Machine cleaning wipes

Healthcare wipes

Do You Still Have Questions? We Can Assist You!

Our sales staff is here to help if you can’t find the answer you’re looking for. Please contact us if you have any questions about our products, prices, or anything else; we would be happy to assist you!