1. Sustainable Sourcing of Materials

A significant change in the wet wipes sector is the move towards procuring materials in a sustainable manner, which has a profound effect. Historically, wet wipes have been manufactured using synthetic fibers such as polyester and polypropylene, both of which are produced from petroleum and have limited biodegradability. These materials make a substantial contribution to environmental pollution, remaining in landfills and natural habitats for many decades. In response to this problem, numerous wet wipes manufacturers are currently choosing to use biodegradable substitutes such as bamboo, organic cotton, and other natural fibers. These materials degrade more rapidly than their synthetic counterparts, hence substantially decreasing the long-term environmental consequences.

For example, bamboo is an extremely sustainable plant that grows rapidly without using pesticides or large amounts of water. The plant can be picked without causing its death, therefore making it a sustainable resource. Conversely, organic cotton is cultivated utilizing techniques and substances that have a minimal ecological footprint. This encompasses the utilization of organic fertilizers and pest management techniques derived from nature, together with the implementation of crop rotation strategies aimed at preserving soil vitality. Wet wipes manufacturers are reducing their environmental impact and meeting the increasing consumer demand for sustainable products by obtaining these environmentally friendly materials.

Furthermore, the transition to sustainable procurement frequently entails the creation of fresh supply networks that prioritize ethical standards. Wet wipes manufacturers are progressively collaborating with suppliers who adhere to fair trade principles, guaranteeing that the people involved in creating raw materials are treated equitably and compensated with a pay that covers their basic needs. This comprehensive approach to sustainability includes both environmental care and social responsibility, resulting in a more fair and sustainable industry. Wet wipes manufacturers are showcasing their ability to create top-notch, efficient products while also prioritizing the well-being of the environment and humanity.

2. Innovative Manufacturing Processes

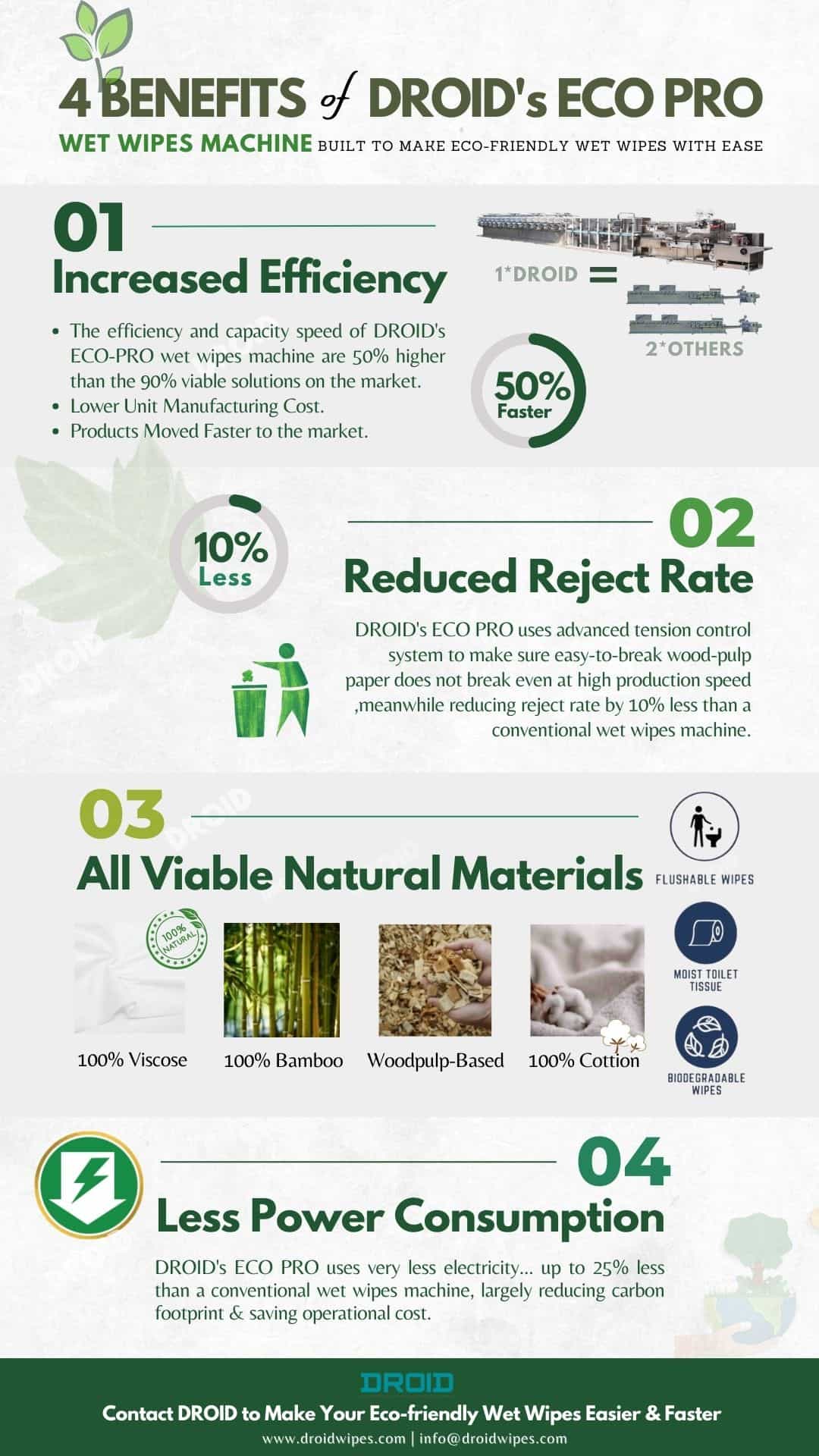

Wet wipes manufacturers are embracing cutting-edge technologies and novel manufacturing processes to boost sustainability. Traditional manufacturing methods are frequently resource-intensive, consuming enormous amounts of energy and water, and generating significant waste. To solve these concerns, corporations are employing modern technology and automated systems that enhance production efficiency and minimize environmental effects.

One major innovation is the use of energy-efficient technology. These wet wipes machines are designed to run with minimal energy usage, decreasing the carbon footprint of the production process. In some facilities, renewable energy sources such as solar and wind power are being integrated to further minimize reliance on fossil fuels. By using renewable energy, wet wipes manufacturers may considerably cut down on greenhouse gas emissions related with production.

Water conservation is another key feature of modern manufacturing processes. Traditional wet wipes manufacturing might be water-intensive, however, modern processes are focused on lowering water usage. This includes the implementation of closed-loop water systems that recycle and reuse water inside the production process. These systems not only conserve water but also limit the outflow of wastewater, which can contain dangerous chemicals and contaminants.

Automation and AI-driven technologies are transforming the manufacturing sector. Automated systems provide precision in the production process, decreasing waste by avoiding errors and optimizing resource use. AI can assess data in real time, altering production parameters to boost productivity and eliminate material waste. For instance, AI can identify and repair any faults in real time, guaranteeing that only high-quality items are produced, thus eliminating the need for rework and lowering material wastage.

The use of zero-waste manufacturing processes is also increasing in popularity. These procedures strive to ensure that every fragment of material is utilized, and nothing is abandoned. Surplus fibers and leftover pieces, typically regarded as garbage, are currently being gathered and recycled to create new items. This not only minimizes waste but also generates additional income from byproducts. Wet wipes manufacturers are actively investigating innovative methods to reuse by-products, such as transforming them into insulating materials or packaging that may be composted.

In addition, certain businesses are allocating resources to research and development to provide environmentally acceptable wetting agents and preservatives. Conventional wet wipes frequently contain chemicals that have the potential to cause harm to the environment. Companies are enhancing the safety of their products for consumers and the environment by creating natural and biodegradable alternatives. These updated formulations preserve the efficacy of the wipes while minimizing their ecological footprint.

Wet wipes manufacturers are making notable progress in sustainability through the implementation of these advanced manufacturing techniques. By efficiently utilizing resources, minimizing waste, and adopting renewable energy, the sector is not only saving expenses but also laying the foundation for a more environmentally friendly future. These improvements illustrate the compatibility of sustainability and efficiency, resulting in a more conscientious and sustainable industrial industry.

3. Eco-Friendly Packaging

Sustainable packaging is an essential element of the wet wipes industry’s attempts to promote environmental friendliness. Conventional packaging frequently depends on disposable plastics, which exacerbates the escalating issue of plastic pollution. Wet wipes manufacturers are becoming more aware of the need to lessen their environmental impact and are therefore adopting sustainable packaging options that correspond with consumer preferences for eco-friendly products.

Utilizing recyclable materials is a key approach to attain environmentally-friendly packaging. Wet wipes manufacturers are currently utilizing packaging composed of recycled plastics or other materials that can be recycled. This method facilitates the completion of the materials’ life cycle by guaranteeing that packaging may be recycled and reused on several occasions. By integrating recycled materials, manufacturers decrease the need to produce new plastic, which requires a significant amount of energy and has negative impacts on the environment.

Compostable packaging is becoming increasingly common, alongside recyclable materials. Compostable packaging is composed of organic materials that biodegrade spontaneously in composting conditions, without leaving any detrimental leftovers. Compostable packaging for wet wipes is often made from materials such as cornstarch, cellulose, and other polymers derived from plants. These materials undergo rapid and safe decomposition, hence lessening the strain on landfills and lowering environmental damage.

Another novel strategy is the utilization of biodegradable packaging. Biodegradable packaging, although comparable to compostable materials, does not necessitate specific composting conditions for decomposition. It undergoes natural degradation over time, especially in situations where composting is not possible. This form of packaging guarantees that even if the material is disposed of in a landfill or natural environment, it will break down at a faster rate compared to conventional plastics.

Wet wipes manufacturers are also investigating the utilization of minimalist package designs to minimize the amount of materials used. Through the process of optimizing packaging design, organizations can achieve substantial savings in the quantity of material needed. By utilizing thinner films, smaller containers, and efficient forms, it is possible to reduce the amount of packaging material used without sacrificing the quality of the product or the convenience for the user. This not only diminishes the ecological impact but also decreases expenses linked to packaging manufacturing and delivery.

Some wet wipes manufacturers are exploring novel materials that are both sustainable and offer extra environmental advantages in their pursuit of eco-friendly packaging. Seaweed-based packaging is a nascent option that provides a renewable and biodegradable substitute for plastic. Seaweed exhibits rapid growth and does not engage in competition with food crops for land or water resources, rendering it an exceptionally sustainable choice. Seaweed-based packaging is both biodegradable and potentially edible, hence further minimizing waste.

Effective eco-friendly packaging techniques require clear labeling and comprehensive consumer education. Wet wipes manufacturers are progressively including instructions on packaging regarding the appropriate methods of disposal or recycling of the materials. This entails utilizing easily identifiable recycling indicators, furnishing guidelines for composting, and enlightening consumers about the advantages of environmentally conscious packaging. Wet wipes manufacturers can improve the success of their environmentally friendly efforts by providing consumers with the information they need to make sustainable decisions.

Ultimately, the advancement of inventive resealable packaging alternatives aids in the reduction of waste. Resealable packaging preserves the product’s freshness by retaining its moisture and safeguarding it from contamination. This decreases the probability of consumers disposing of unused or spoilt wipes, hence reducing waste.

Wet wipes manufacturers are making tremendous progress in lowering their environmental impact by implementing various eco-friendly packaging methods. The industry is progressing towards a more sustainable future by implementing recyclable, compostable, and biodegradable materials, improving packaging designs, and educating consumers. These initiatives not only tackle the urgent problem of plastic pollution but also cater to the increasing customer desire for ethical and environmentally friendly products.

4. Reducing Carbon Footprint

Wet wipes manufacturers who are dedicated to sustainability place great emphasis on minimizing their carbon footprint. The carbon footprint of a product includes all the greenhouse gas emissions generated during its entire existence, including the extraction of raw materials, production, transportation, usage, and disposal. Wet wipes manufacturers are actively contributing to the battle against climate change and fostering a more sustainable industry by implementing initiatives to reduce these emissions.

Adopting renewable energy sources is a key strategy for lowering carbon emissions. Several wet wipes manufacturers are shifting from fossil fuels to sustainable energy sources, including solar, wind, and hydroelectric power. By installing solar panels on industrial rooftops and obtaining energy from wind farms, the amount of carbon dioxide emissions linked to energy usage is greatly reduced. Renewable energy sources not only diminish the amount of carbon emissions but also offer enduring financial benefits and guarantee a stable energy supply.

Wet wipes manufacturers are making significant advancements in the area of energy efficiency. By implementing energy-efficient gear and streamlining production processes, wet wipes manufacturers can minimize the energy consumption needed for the manufacturing process. Energy savings in manufacturing facilities are significantly enhanced by the implementation of innovations such as high-efficiency motors, improved heat recovery systems, and LED lighting. Moreover, the implementation of energy management systems enables wet wipes manufacturers to actively monitor and regulate energy consumption in real time, thereby discovering potential areas for additional reductions.

Wet wipes make a substantial contribution to carbon emissions through transportation. In response to this issue, wet wipes manufacturers are enhancing the efficiency of their logistics and supply networks. Strategies encompass employing local procurement of raw materials to minimize transportation distances, utilizing vehicles with higher fuel efficiency, and consolidating shipments to optimize load efficiency. Additionally, certain wet wipes manufacturers are investigating the utilization of electric or hybrid cars for delivery purposes, thereby further diminishing emissions resulting from transportation.

The choice of materials is crucial in minimizing the carbon footprint. Wet wipes manufacturers can decrease the emissions linked to the extraction and processing of raw materials by opting for sustainable materials with low environmental effects. Utilizing recycled or biodegradable materials frequently leads to reduced carbon emissions in comparison to utilizing new plastics. Furthermore, advancements in material science are driving the creation of novel, environmentally-friendly materials that have a reduced carbon footprint.

Wet wipes manufacturers are also prioritizing waste reduction throughout the production process. Reducing trash not only preserves resources but also decreases the emissions linked to waste disposal and management. Adopting lean manufacturing concepts facilitates the optimization of operations, minimizes material waste, and enhances overall efficiency. Wet wipes manufacturers can decrease their total carbon emissions by minimizing scrap rates and recycling production waste.

Wet wipes manufacturers are utilizing carbon offset schemes as a means to tackle their carbon impact. These programs entail investment in initiatives that mitigate or capture greenhouse gas emissions, such as afforestation, renewable energy projects, and methane capture from landfills. By endorsing these programs, firms can compensate for the emissions they are unable to eradicate, so effectively diminishing their overall carbon footprint.

Lifecycle analysis (LCA) is becoming crucial for wet wipes manufacturers seeking to diminish their carbon footprint. Life Cycle Assessment (LCA) is the process of evaluating the environmental effects of a product from its inception to its disposal, with a focus on identifying areas where carbon emissions are particularly high. Wet wipes manufacturers can make informed decisions about implementing reductions and improvements by comprehending the emissions linked to each step of the product lifecycle, ranging from raw material extraction to end-of-life disposal.

Collaboration and transparency are crucial in endeavors to decrease carbon emissions. Several wet wipes manufacturers are collaborating with suppliers, consumers, and environmental organizations to create and execute optimal methods for reducing carbon emissions. Ensuring transparency in the reporting of emissions and the assessment of progress towards reduction targets is of utmost importance. Through transparently divulging their objectives and accomplishments, corporations may establish confidence with customers and stakeholders, showcasing their dedication to sustainability.

To summarize, the process of reducing the carbon footprint in wet wipes manufacturing requires a comprehensive strategy that encompasses various aspects such as implementing renewable energy sources, enhancing energy efficiency, optimizing transportation methods, choosing sustainable materials, minimizing waste generation, supporting carbon offset initiatives, and conducting lifecycle analysis. By implementing these comprehensive techniques, wet wipes manufacturers can effectively decrease their greenhouse gas emissions, so making a substantial contribution to creating a more sustainable and environmentally conscientious industry. As these techniques grow more prevalent, the wet wipes industry will have a vital part in the worldwide endeavor to address climate change and advance a more environmentally friendly future.

5. Biodegradable and Flushable Wipes

The advancement of biodegradable and flushable wipes in the wet wipes sector is a big step towards improving sustainability. Conventional wet wipes frequently include non-biodegradable plastic fibers, which contribute to environmental contamination and clog sewage systems. Wet wipes manufacturers are responding to these difficulties by developing wipes that are both biodegradable and flushable, providing a more ecologically sound option.

Biodegradable Wipes

Biodegradable wipes are specifically engineered to decompose organically over some time, hence minimizing their ecological footprint. These wipes are commonly manufactured using natural fibers like bamboo, organic cotton, and wood pulp, which break down more quickly than synthetic materials. By utilizing biodegradable components, the wipes are designed to decompose quickly, reducing their impact on both landfills and the contamination of oceans.

The manufacturing method of biodegradable wipes frequently entails reducing the usage of chemicals and increasing the utilization of natural preservatives. This not only enhances the safety of the wipes for users but also diminishes the environmental footprint of their production. Wet wipes manufacturers may produce effective and sustainable products by opting for eco-friendly materials and techniques.

Flushable Wipes

Flushable wipes are designed to rapidly break down in water, preventing clogs in sewage systems and decreasing the likelihood of environmental pollution. Unlike conventional wipes, which can lead to substantial plumbing and environmental problems when flushed, these wipes are specifically engineered to fast decompose after being disposed of. This function is especially crucial in urban areas where sewer systems are frequently overwhelmed by non-biodegradable trash.

Developing really flushable wipes requires thorough testing to guarantee that they adhere to strict criteria for dispersibility. These criteria, typically established by industry and environmental standards bodies, mandate that wipes disintegrate rapidly in water and do not result in blockages or other problems in wastewater treatment plants. Wet wipes manufacturers engage in thorough research and testing to create formulas that achieve a delicate balance between durability during use and quick breakdown after disposal.

Innovations in Biodegradability and Flushability

Advancements in material science are currently enhancing the biodegradability and flushability of wet wipes. Scientists are currently working on creating improved fibers and binders that can enhance the decomposition process of wipes, while yet maintaining their strength and utility. For example, certain businesses are currently conducting trials using plant-derived adhesives that effectively bind the fibers together while readily dissolving in water, thereby facilitating the disintegration process.

Furthermore, sophisticated manufacturing techniques are being utilized to create wipes that possess both durability and the ability to be flushed. These techniques involve the construction of layered structures, where the inside layers offer robustness while the exterior layers are specifically engineered to rapidly disintegrate. This method guarantees that the wipes are very efficient during usage, while also being able to decompose effectively when flushed.

Advantages for the Environment and Consumers

The transition to biodegradable and flushable wipes presents notable ecological advantages. These items help to mitigate plastic waste and prevent sewage obstructions, thereby promoting cleaner waterways and lowering the burden on waste management systems. In addition, the utilization of natural, biodegradable materials frequently leads to a reduced carbon impact in comparison to synthetic equivalents.

Biodegradable and flushable wipes offer a practical and environmentally conscious option for consumers. These wipes provide equivalent hygiene and convenience to conventional products, while also ensuring that they are more environmentally friendly. Effective labeling and customer education are crucial to ensure that consumers comprehend the appropriate disposal techniques for these wipes, maximizing their environmental advantages.

Industry Collaboration and Standards

Collaboration throughout the industry is frequently necessary for the development of biodegradable and flushable wipes. Wet wipes manufacturers, environmental organizations, and regulatory bodies collaborate to set standards and testing processes that guarantee the effectiveness of products and their safety for the environment. These partnerships facilitate the advancement of new ideas and guarantee that goods adhere to rigorous criteria for effectiveness and environmental responsibility.

Wet wipes manufacturers can confidently promote their products by following these criteria, as they ensure that the items fit both customer expectations and environmental requirements. Adherence to industry-wide standards fosters consumer confidence by ensuring that purchasers can depend on uniform quality and performance across various brands.

The use of biodegradable and flushable wipes represents a notable advancement in the wet wipes industry’s dedication to sustainability. Wet wipes manufacturers are tackling pressing environmental issues and offering consumers efficient and convenient hygiene solutions by creating items that biodegrade organically and can be securely disposed of by flushing. By consistently implementing new ideas and working together, the industry is ready to achieve even more significant progress in minimizing its ecological footprint and advocating for a more sustainable future.

6. Consumer Education and Engagement

The success of sustainable practices within the wet wipes business heavily relies on consumer education and engagement. In order to fully experience the environmental benefits of eco-friendly products, customers must be well-informed on the appropriate methods of usage and disposal. Wet wipes manufacturers are increasingly realizing the significance of educating and involving consumers to promote responsible habits and optimize the effectiveness of their sustainability projects.

Educating Consumers on Product Use and Disposal

The main objective of consumer education is to educate customers about the proper utilization and disposal of moist towelettes. Most customers are unaware that flushing conventional wet wipes can lead to significant obstructions in sewer systems and cause damage to aquatic areas. Wet wipes manufacturers can effectively steer consumers toward ethical disposal procedures by employing explicit product labeling and offering comprehensive instructions. Labels frequently have symbols and words that indicate whether a product is suitable for flushing or should be discarded in a garbage receptacle.

Wet wipes manufacturers employ diverse platforms to educate consumers, in addition to labeling. Social media campaigns, instructional videos, and infographics are efficient means of promoting awareness of the environmental consequences of inappropriate waste disposal and the advantages of use biodegradable and flushable wipes. Educational information can illustrate the process of distinguishing between flushable and non-flushable wipes and elucidate the appropriate techniques for disposing of each category.

Promoting the Benefits of Eco-Friendly Products

Consumer participation entails emphasizing the benefits of utilizing environmentally friendly products. Wet wipes manufacturers might highlight the ecological advantages of biodegradable and flushable wipes, such as diminished plastic pollution and alleviated pressure on sewage systems. Companies can promote the use of sustainable products by highlighting the favorable influence that individual acts can exert on the environment.

Marketing strategies that stress the environmentally beneficial characteristics of wet wipes can also generate customer interest. Emphasizing characteristics such as the use of biodegradable materials, packaging that can be composted, and a minimal carbon footprint can enhance the attractiveness of eco-friendly wipes to consumers who prioritize environmental sustainability. In addition, receiving endorsements from environmental organizations and obtaining certifications from renowned eco-labeling agencies can strengthen the credibility of a product and increase consumer trust.

Encouraging Responsible Consumer Behavior

In addition to education, involving customers in sustainability activities include promoting responsible behavior. Wet wipes manufacturers can advocate for efforts such as the implementation of recycling programs, the adoption of composting practices, and the utilization of reusable items. For instance, providing incentives such as discounts or loyalty points for returning used packaging for recycling might incentivize consumers to engage in waste reduction initiatives.

Engaging customers can be effectively achieved through community involvement. Engaging in clean-up events, collaborating with local environmental organizations, and taking part in sustainability fairs can provide consumers with opportunity to actively participate in environmental initiatives. These events serve the purpose of not only increasing awareness but also cultivating a sense of community and collective responsibility towards environmental protection.

Transparency and Communication

Transparency has a crucial role in establishing customer trust and promoting active involvement. Wet wipes manufacturers ought to engage in transparent communication regarding their sustainable policies, objectives, and advancements. Offering details regarding the acquisition of materials, manufacturing procedures, and ecological consequences aids consumers in making well-informed choices. Annual sustainability reports, blog postings, and press releases serve as effective means to communicate updates and accomplishments, thereby strengthening the company’s dedication to environmental responsibility.

Consumers can directly communicate with wet wipes manufacturers using interactive platforms, such as company websites and social media profiles. These platforms are utilized for the purpose of responding to inquiries, resolving issues, and collecting input. Through the practice of keeping a transparent and ongoing conversation, organizations can gain a deeper comprehension of consumer requirements and inclinations, enabling them to customize their products and projects accordingly.

Leveraging Technology for Consumer Engagement

Technology provides novel methods to educate and captivate people. Mobile applications, such as those found on smartphones, have the capability to offer users valuable knowledge regarding sustainable lifestyles, strategies for waste reduction, and the latest developments in environmentally friendly items. Augmented reality (AR) elements can be utilized to visually illustrate the process of disintegration of biodegradable wipes or showcase the path taken by recycled materials, hence enhancing the tangibility and engagement of the information.

Gamification is an additional approach to encourage and support sustainability. Wet wipes manufacturers can design interactive challenges or reward systems that motivate consumers to embrace environmentally responsible behaviors. For example, a mobile application might monitor and incentivize users to correctly dispose of wet wipes or engage in recycling initiatives.

Consumer education and involvement are essential for the success of sustainable practices in the wet wipes sector. To cultivate a more environmentally aware consumer base, producers can achieve this by educating consumers on the correct usage and disposal of products, emphasizing the advantages of eco-friendly products, promoting responsible behavior, ensuring transparency, and utilizing technology. These endeavors not only improve the efficiency of sustainability endeavors but also contribute to a wider cultural transformation towards environmental accountability. By continuously educating and involving consumers, the wet wipes business has the potential to catalyze substantial improvements in consumer behavior and environmental sustainability.

7. Collaborating for Sustainability

Collaboration is a potent weapon for wet wipes manufacturers in their endeavor to achieve sustainability. Wet wipes manufacturers can enhance their environmental effects by collaborating with diverse stakeholders such as suppliers, industry peers, government agencies, and environmental NGOs. Collaboration facilitates the sharing of ideas, resources, and best practices, which promotes the creation of inventive solutions and the establishment of elevated benchmarks for sustainability throughout the industry.

Collaborating with Suppliers

Engaging in collaboration with suppliers is essential for the procurement of sustainable resources. Through close collaboration with suppliers, manufacturers may guarantee that the raw materials utilized in their goods are ethically obtained and manufactured with minimal ecological consequences. This typically entails choosing suppliers that comply with stringent environmental and ethical criteria, such as employing organic farming methods or utilizing renewable resources. Collaborative efforts with suppliers can also result in the creation of novel, environmentally friendly materials and technologies.

For instance, a wet wipes manufacturer could engage in a partnership with a supplier to create a novel form of biodegradable fiber that satisfies both performance and environmental standards. Manufacturers may stimulate innovation in the supply chain and produce high-quality, environmentally friendly products by investing in these collaborations.

Industry-Wide Collaborations

Engaging in cooperation with colleagues in the industry is an additional successful approach for promoting and progressing sustainability. Through collaboration with other manufacturers, companies can pool their knowledge and resources to address shared difficulties. Industry groups and consortia frequently encourage these relationships, offering a venue for corporations to collaborate on sustainability efforts.

These collaborations can result in the establishment of industry-wide norms and optimal procedures, which ensure that all enterprises adhere to rigorous environmental requirements. Industry groups can create standards for the biodegradability and flushability of wet wipes, guaranteeing uniformity and dependability across different products. These guidelines have a dual advantage of both promoting environmental well-being and fostering consumer trust and confidence in the sector.

Interacting with Government and Regulatory Authorities

Government agencies and regulatory entities have a crucial function in advancing sustainability. By actively interacting with these bodies, manufacturers of wet wipes can contribute to the development of laws and regulations that promote environmental objectives. Government collaboration can facilitate access to financing, resources, and incentives for sustainability projects.

Wet wipes manufacturers have the opportunity to engage in government-sponsored research projects aimed at creating novel sustainable materials or production techniques. In addition, they can promote legislation that supports the practice of recycling, composting, and the utilization of renewable energy sources. Through collaboration with regulators, manufacturers can contribute to the establishment of a conducive policy framework that bolsters their sustainable endeavors.

Partnering with Environmental Organizations

Environmental organizations play a crucial role in the pursuit of sustainability. These organizations possess specialized knowledge, a reputation for reliability, and a powerful platform for promoting and supporting manufacturers in enhancing their environmental performance. Collaborations with environmental groups may encompass cooperative scientific endeavors, public outreach efforts, and endeavors aimed at safeguarding natural environments.

For instance, a wet wipes manufacturer could collaborate with an environmental non-governmental organization (NGO) to initiate a campaign that advocates for the correct disposal of moist towelettes and highlights the advantages of using biodegradable products. These agreements may also include participation in certification programs, where items undergo independent verification to ensure they meet certain environmental criteria. Obtaining these certifications can improve the attractiveness of sustainable products in the market and provide consumers with confidence in their environmental advantages.

Cooperative Research and Innovation

Research and innovation are crucial in promoting sustainability, and collaboration can expedite development in these domains. Manufacturers have the opportunity to collaborate with universities, research organizations, and technology corporations to create innovative materials, production methods, and waste management strategies. Collaborative research projects can harness the capabilities and specialized knowledge of multiple companies, resulting in significant advancements that may not be attainable by any single entity.

An example of a collaborative research effort could involve investigating the application of innovative biodegradable materials to minimize the ecological footprint of wet wipes. Through the combination of resources and specialized knowledge, these projects have the potential to create economically feasible solutions that establish higher benchmarks for sustainability.

Establishing Resilient Societies

Collaboration goes beyond the production process and includes the creation of sustainable communities. Wet wipes manufacturers can promote environmental education, conservation projects, and community-driven sustainability programs by actively involving themselves with local communities. These endeavors contribute to the establishment of a sustainable culture that encompasses both the manufacturing process and the end consumer.

For instance, a business may endorse local environmental restoration endeavors, afforestation campaigns, or instructional projects in schools. These collaborations, which are grounded in the community, not only improve the company’s reputation but also contribute to wider environmental and social objectives.

For wet wipes manufacturers who want to have a substantial environmental effect, it is crucial to work together towards sustainability. Wet wipes manufacturers can foster innovation, establish elevated benchmarks, and advocate for optimal procedures throughout the sector by collaborating with suppliers, industry peers, government agencies, environmental organizations, and research institutes. These cooperative endeavors contribute to the development of a more sustainable future, yielding advantages for both the environment and society at large. By maintaining ongoing collaboration and a shared dedication, the wet wipes business can serve as a model for showcasing how cooperative strategies can effectively accomplish significant and enduring sustainability.