1. Real-Time Monitoring and Process Control

In the creation of wet wipes, real-time monitoring entails the ongoing gathering of data from several devices and procedures throughout the production line. The gear is equipped with sophisticated sensors and Internet of Things (IoT) technology to collect vital data on speed, material use, energy consumption, and product quality. A centralized system receives this data and uses it to provide operators with real-time information about how things are operating. Wet wipes manufacturers can monitor performance, spot inefficiencies quickly, and react to any deviations from ideal circumstances since they have access to real-time data. This guarantees that all wet wipes manufacturing processes are operating as smoothly and effectively as possible.

The capacity to make quick modifications is one of real-time monitoring’s greatest benefits. The system promptly notifies the operators if it discovers an abnormality, such as an increase in energy consumption or a decrease in material efficiency. When a wet wipes machine begins to consume more material or waste more liquid solution, for instance, the monitoring system’s data enables operators to identify and fix the issue before it becomes worse. By taking a proactive stance, manufacturers may optimize resource utilization and maintain production quality by cutting waste, minimizing downtime, and preventing the fabrication of faulty goods.

Furthermore, real-time monitoring and process management enable wet wipes producers to lessen their environmental impact. The system’s continuous monitoring of excessive material or energy usage encourages resource efficiency, an important aspect of sustainable corporate operations. Monitoring important environmental parameters, such as energy and water use, enables businesses to take focused action to cut waste production and carbon emissions. Because of this, real-time monitoring and process control assist environmentally friendly production techniques in addition to increasing operational efficiency.

2. Precision Cutting and Material Optimization

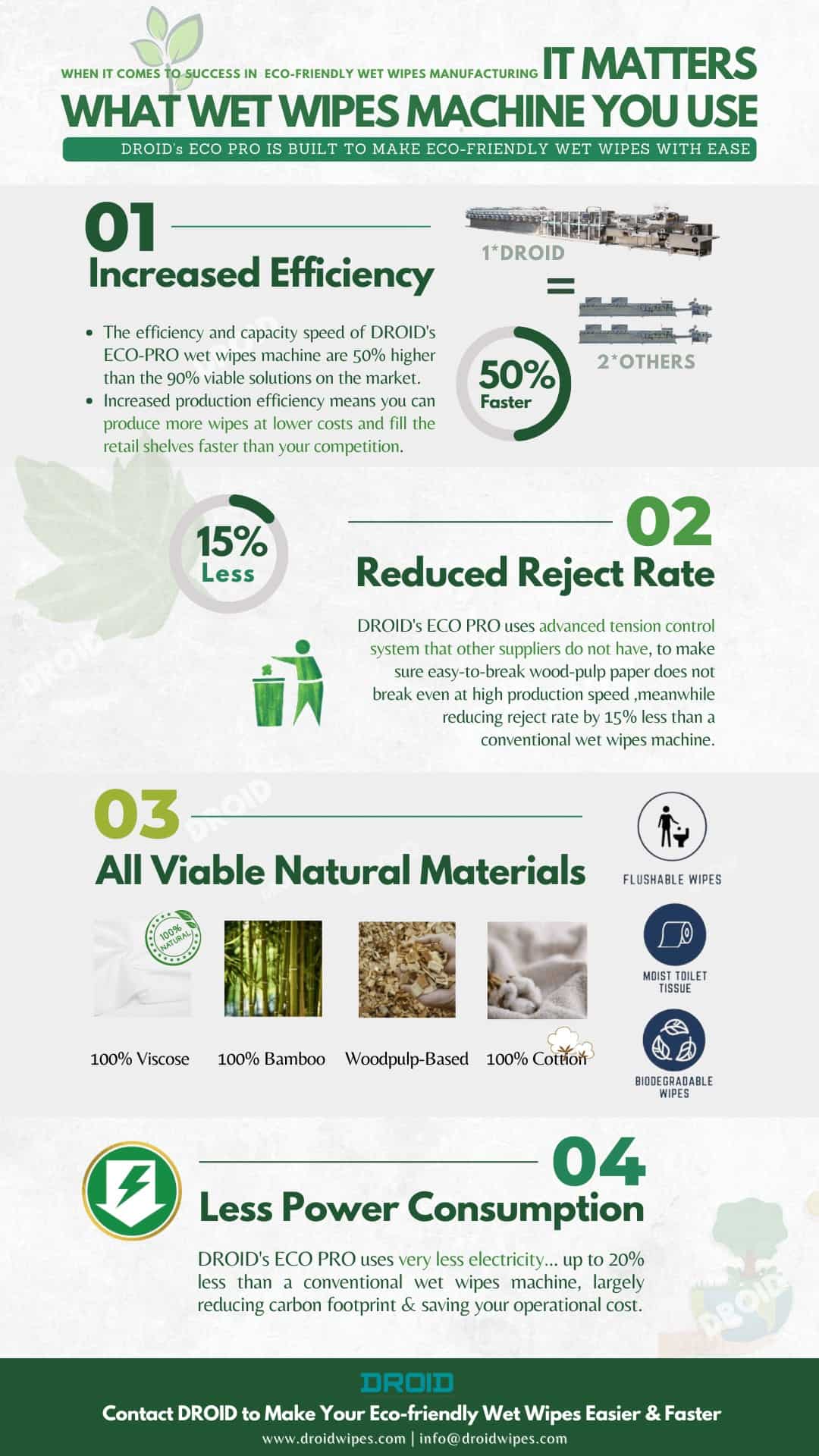

A key component of the production of wet wipes is precision cutting, which guarantees that every wipe is made with precise measurements and little waste. This degree of accuracy is intended to be achieved by intelligent machines that are outfitted with automated or laser-guided cutting technology. Modern cutting equipment employs sophisticated algorithms to optimize the cutting process, in contrast to conventional techniques that may lead to uneven cuts and substantial material loss. With minimal to no off-cuts, these machines are designed to determine the most effective method to cut the cloth. Minimizing the quantity of material lost decreases manufacturing costs in addition to conserving raw supplies.

Precision cutting has advantages beyond lowering waste. Wet wipes manufacturers may maintain a constant level of product quality by making sure that every wipe is cut precisely according to the standards. This is especially crucial in markets that are competitive because customers need consistency in the size and functionality of products. With the least amount of mistakes possible, smart machines enable wet wipes manufacturers to make wet wipes that adhere to exacting quality requirements. Additionally, the technology allows for easy alterations, such as changing wipe sizes or shapes for different purposes, allowing for quick product changes or customization to suit unique market needs.

Precision cutting and material optimization go hand in hand because they both aim to maximize resource use. Apart from guaranteeing precise cuts, intelligent devices can modify the material’s arrangement to reduce wastage. To avoid wasted scraps, they might, for instance, organize the wipes such that they use the whole width of the cloth roll. The appropriate quantity of lotion or cleaning solution may be dispensed with each wipe by using this optimization technique. Wet wipes manufacturers may contribute to sustainability and profitability by obtaining a better yield from the same quantity of wet wipes raw material while drastically reducing costs via the optimization of both the cutting and material consumption processes.

3. Automated Liquid Dispensing Systems

The production of wet wipes has changed dramatically with the introduction of automated liquid dispensing systems, which guarantee accurate and reliable dousing of each wipe with disinfectants, lotions, or cleaning solutions. The precise amount of liquid dispensed is controlled by sensors and algorithms in these cutting-edge systems, avoiding oversaturation or underapplication. The product quality was inconsistent in traditional liquid dispensing technologies because they often depended on hand adjustments or inaccurate gear. However, by accurately regulating the flow rate and volume, automated systems remove these anomalies and guarantee that each wipe has the same quantity of liquid, improving product dependability and customer satisfaction.

Beyond guaranteeing product uniformity, automated liquid dispensing systems provide other benefits. They also avoid the abuse of expensive liquid substances, which considerably reduces waste. In the past, extra liquid was often thrown away during quality control or allowed to seep into the manufacturing line throughout the operation. Because automated systems only use as much liquid as is required, they conserve resources and lessen the need for cleaning and maintenance because there are no spills or overflows. This economical utilization of resources enables producers to reduce expenses while maintaining strict quality control requirements.

Automatic liquid dispensing systems can help to increase production rates without sacrificing quality. These technologies blend smoothly into the production process, adapting in real-time to the production pace and the particular needs of every product line. The system may be adjusted to dispense the precise formula needed for any kind of product, regardless of whether the wipes are intended for industrial, cleaning, or infant care applications. With less downtime and quicker production changeovers made possible by this degree of flexibility, wet wipes manufacturers may swiftly switch between various kinds of wet wipes, increasing overall production efficiency and throughput.

4. Reduced Energy Consumption Through Smart Controls

By maximizing the timing and efficiency of machine power use, smart controls play a critical role in lowering energy consumption in the production of wet wipes. These controls are equipped with cutting-edge sensors and artificial intelligence (AI) algorithms that track the energy use of different devices and processes in real-time. Smart systems can automatically modify power use depending on current production demands by collecting data on energy usage. For instance, wet wipes machines may be programmed to shut down or switch to energy-saving modes while they are idle or in between production cycles. This dynamic adjustment lowers operating costs and minimizes environmental impact while helping wet wipes manufacturers drastically cut energy waste.

One major advantage of lowering energy use with smart controls is that machines may be adjusted for maximum efficiency. Conventional equipment often operates at maximum capacity regardless of real production needs, using needless energy. On the other hand, intelligent controls can adjust the temperature, pressure, or speed of machinery based on data that is updated in real-time. For example, smart controls may reduce machine speed to conserve energy without sacrificing output quality under lower production loads. In large-scale operations, where even modest energy savings across many units may result in considerable reductions in total electricity usage, this intelligent power management is very helpful.

In addition to the immediate energy savings, wet wipes manufacturers may more easily integrate renewable energy sources into their operations with the help of smart controls. When renewable energy is available, these systems may be configured to utilize it first, fluidly switching between grid power, solar power, and wind power as required. Additionally, wet wipes manufacturers may qualify for government subsidies or energy rebates by lowering energy use and increasing overall efficiency, which would further save expenses. In addition to increasing their bottom line, manufacturers are better positioned to satisfy customer demand for eco-friendly goods and regulatory requirements thanks to this combination of reduced energy use, increased operational efficiency, and environmental sustainability.

5. Waste Management and Recycling Capabilities

Because smart machines incorporate recycling capabilities straight into production lines, they are redefining waste management in the wet wipes industry. Waste from traditional production methods, such as leftover fabric, extra packing, and wasted liquids, is often rather large. However, by real-time monitoring and the recycling of leftover resources, contemporary smart devices are made to decrease this waste. For instance, leftover cloth may be gathered, recycled back into the manufacturing stream, or used to make new items. Comparably, extra liquid solutions that are surplus, such as lotions or cleaning supplies, may be collected and repurposed to prevent the loss of important resources in the production process.

There are two advantages to integrating recycling capabilities into the production process: it decreases the amount of trash that ends up in landfills and it uses less new raw resources. Manufacturers may lower their environmental impact and resource costs by recycling off-cuts and other by-products. With the help of this closed-loop technology, producers may maximize output while reducing waste and more efficiently use their resources. Furthermore, incorporating waste management systems into production lines enables enterprises to comply with ever-tougher environmental requirements, many of which call for waste reduction and increased operational sustainability.

Additionally, data-driven insights from smart equipment might eventually enhance waste management. These devices are capable of monitoring the precise amount of waste generated at every step of manufacturing and determining the causes of it. Wet wipes manufacturers may modify their processes to further decrease waste with the use of this knowledge. For instance, operators may identify the problem and make the required changes if a certain step of production produces more material waste than anticipated. Wet wipes manufacturers that consistently enhance their waste management procedures not only support environmental initiatives but also increase their profitability by reducing expenses associated with resource acquisition and trash disposal.

6. Eco-Friendly Packaging Solutions

Wet wipes manufacturers are now placing a lot of emphasis on eco-friendly packaging options in response to the increased customer demand for sustainable goods. These days, intelligent machinery is essential to producing packaging that is not only safe and useful but also ecologically friendly. Packaging constructed from recyclable, compostable, or biodegradable materials—such as plant-based plastics, recycled paper, or other sustainable substitutes—can be produced using these wet wipes machines. Wet wipes manufacturers may cater to environmentally concerned customers who value sustainability in their purchase choices by using these materials, which greatly lessen the environmental effect of their packaging.

Intelligent devices are designed to reduce the quantity of materials used during the packaging process while preserving the quality of the final product. They do this by making sure the packaging is as durable and protective as possible while using fewer resources by optimizing its structure and design. For instance, wet wipes manufacturers may cut down on material waste while yet guaranteeing that the packaging is sturdy enough to safeguard the product during handling and transportation thanks to developments like stronger but thinner packaging films and less plastic in wipes’ containers. In addition to lowering material costs, these efficiency improvements assist wet wipes manufacturers in adhering to eco-friendly certifications and requirements, which may enhance their market reputation.

In addition to using less material, smart machines provide wet wipes manufacturers with alternatives for customized packaging, enabling them to customize packaging to meet particular market needs or regulatory requirements. For example, certain markets could want entirely biodegradable packaging, while others might have recycling programs that call for alternative packaging materials. Intelligent equipment can instantly adjust to these specifications, creating packaging that complies with legal and environmental regulations. This flexibility helps wet wipes manufacturers to stay compliant in international markets while cutting waste and their carbon footprint—all of which contribute to the brand’s eco-friendly image and larger sustainability objectives.

7. Data-Driven Decision Making for Continuous Improvement

Modern wet wipes production has made data-driven decision-making a pillar of operations, enabling wet wipes manufacturers to constantly optimize their workflows for increased productivity and less waste. Massive volumes of data are collected at every step of production, from wet wipes raw material used to measures related to product quality, by intelligent machines outfitted with cutting-edge sensors and analytical tools. Real-time analysis of this data provides manufacturers with important insights into resource use, inefficiencies, and production optimization. Wet wipes manufacturers may make educated judgments to adjust processes, boost output, and save expenses by utilizing this information.

An important benefit of data-driven decision-making is its capacity to identify and solve issues at an early stage. For instance, the system would mark a machine for evaluation if the data indicates that it often uses more energy than anticipated or generates more trash. After that, operators may look into the problem and take remedial measures, such as recalibrating the wet wipes machine or doing maintenance to stop more waste. This proactive strategy ensures easier production and minimizes resource waste by preventing minor difficulties from growing into bigger, more expensive ones.

Data-driven systems not only detect and resolve issues but also facilitate ongoing enhancement by pointing up areas that need more optimization. Wet wipes manufacturers may make long-term strategic choices by identifying patterns and trends via the collection of production data over time. Wet wipes manufacturers could see, for example, that a particular source of wet wipes raw materials produces less waste or that certain machine settings regularly result in higher-quality products. Using this information, wet wipes manufacturers may make little adjustments that add up to more productive, economical, and sustainable manufacturing processes. In addition to increasing operational effectiveness, this continuous cycle of learning and development puts firms in a competitive position in a market that is always changing.

8. The Business Benefits of Smart Machines

Wet wipes manufacturers may achieve considerable commercial advantages by investing in smart equipment, especially in terms of cost reductions and operational efficiency. These wet wipes machines are made to streamline every stage of the wet wipes manufacturing process, from energy and material use to waste reduction and overhead expenses. Wet wipes manufacturers may create more wet wipes with fewer resources by using precise technologies to guarantee that energy, liquids, and raw materials are handled effectively. This results in lower operational costs and a larger profit margin—a crucial outcome in competitive marketplaces where price sensitivity is paramount.

The capacity of smart machines to increase production speed and flexibility is one of their main benefits. Long changeover times are a common problem for traditional production processes when transferring between various products or setups. Conversely, smart machines include sophisticated controls and automation that enable quick changes in product offerings. Because of its adaptability, wet wipes manufacturers may launch new goods or swiftly adjust to changing market needs without experiencing significant production line interruptions. Faster changeovers and the capacity to process several product types on the same piece of equipment enable wet wipes manufacturers to take advantage of new business possibilities and react quickly to market trends.

Furthermore, long-term sustainability is facilitated by smart machinery, which is becoming more in line with customer expectations and legal requirements. Numerous countries provide grants or tax advantages to companies that invest in sustainable or energy-efficient technology. Smart machines minimize waste and use less energy, which helps producers qualify for these advantages. Additionally, companies that use smart manufacturing technology may portray themselves as environmentally sensitive, which will enhance their image in the market as customers become more eco-conscious. For wet wipes producers hoping to maintain long-term profitability and competitiveness, smart machines are a wise investment due to their cost-effectiveness, enhanced production flexibility, and alignment with sustainability objectives.