Essential Equipment and Supplies #1: Wet Wipes Manufacturing Machine

The wet wipes manufacturing machine is the crucial piece of technology at the core of every wet wipes manufacturing plant. It serves as the foundation for a global industry committed to providing customers with comfort, convenience, and cleanliness. This incredible machine transforms raw materials into high-quality wet wipes, making it much more than just a regular piece of machinery.

The wet wipes manufacturing machine is a combination of precise engineering and state-of-the-art technology that enhances the quality of the final product and speeds up the wet wipes manufacturing process. Let’s take a closer look at the complex inner workings of this essential device:

- Fully Automatic Operation: Fully automatic wet wipes manufacturing machines are the most efficient option for hands-free production, as they require little assistance from humans. These robots can manage every step of the production process, from material feeding to packing. They are perfect for production applications with large volumes, thanks to their sophisticated sensors and computerized controls that ensure consistent quality and output.

- Semi-Automatic Versatility: For companies that seek a balance between automation and flexibility, semi-automatic wet wipes manufacturing machines are the ideal choice. These machines require some human operation in addition to automated procedures, allowing operators to monitor production and make adjustments to settings easily. They can handle different production quantities or specialized product compositions, making them adaptable to satisfy a wide range of market needs.

- Precision Engineering: Every part of the wet wipes manufacturing machine is expertly created and manufactured to maximize performance and reliability. Every little element is carefully crafted from the complex mechanics that regulate material flow to the finely sharpened blades that form each unique wipe. This attention to detail guarantees constant product quality and reduces waste, maximizing manufacturer productivity and profitability.

- Customization Capabilities: In a market where customer trends and preferences are driving demand, it is crucial to customize items swiftly and effectively. Wet wipes manufacturing machines provide numerous customization options, allowing wet wipes manufacturers to adjust features like wipe size, thickness, texture, and scent to cater to the demands of their target market. Producers can modify their manufacturing procedures to meet changing customer needs, whether they are producing wipes for babies, removing makeup, or cleaning surfaces.

- Integrated Quality Control: To ensure the integrity and safety of the finished product, it is essential to have a quality control system in place. Many wet wipes manufacturing machines have integrated quality control systems that continuously check important variables such as moisture content, solution concentration, and sealing integrity. These solutions anticipate problems and take proactive measures to resolve them, preserving product consistency and regulatory compliance.

In summary, the wet wipes manufacturing machine is the catalyst for innovation in the hygiene sector and is much more than a regular piece of machinery. With its cutting-edge capabilities, meticulous engineering, and unwavering dedication to quality, this vital device enables manufacturers to produce goods that not only fulfill but surpass customer demands for comfort, ease, and cleanliness.

Essential Equipment and Supplies #2: Non-Woven Fabric

Non-woven fabric is the key component that turns ordinary wipes into exceptional instruments of convenience and cleanliness. Despite being sometimes overlooked, non-woven fabric is incredibly important in determining the functionality, texture, and efficacy of wet wipes. Let’s take a closer look at why non-woven fabric is the unsung hero of the wet wipe production process.

- Superb Absorbency: The ability to absorb moisture effectively is the foundation of every successful wet wipe. Non-woven fabric is designed to perform exceptionally well in this area due to its superior absorbent qualities, allowing it to absorb liquids more quickly and efficiently. This guarantees a uniform distribution of the solution, enhancing the cleaning and sanitizing properties of wipes, and making them ideal for both mildew and disinfection applications.

- Softness and Comfort: Wet wipes’ soothing touch is one of its most sought-after characteristics when applied to sensitive skin. Non-woven fabric provides a velvety, smooth feel that is appreciated for offering a calming sensation with each wipe. Because its fibers are linked together rather than intertwined like regular woven textiles, non-woven fabric has a smooth, non-abrasive surface that is gentle on the skin.

- Durability and Strength: Although softness is essential, wet wipes need to be strong and durable enough to withstand repeated heavy use without tearing or breaking. Non-woven fabric is soft and strong in just the right amounts, offering strong resistance to ripping and fraying without sacrificing its gentleness on the skin. Wet wipes stay intact even after being exposed to severe cleaning or sanitizing procedures due to their resilience.

- Versatility and Customization: Producers can tailor wipes to meet particular needs and preferences by using a vast range of compositions, densities, and textures of non-woven fabric. Non-woven fabric can be adjusted to meet the varying demands of customers across a range of applications, whether the product is thick and absorbent wipes for heavy-duty cleaning activities or ultra-soft and delicate wipes for sensitive skin.

- Compatibility with Formulations: Non-woven fabric is compatible with various formulations, including water-based solutions, alcohol-based sanitizers, and oil-based emollients, in addition to its physical characteristics. Producers can make wet wipes that are safe and effective for numerous uses, from moisturizing and cleaning to disinfecting and deodorizing, thanks to their versatility.

In conclusion, non-woven fabric is the unsung hero of the wet wipes industry, providing a soft base that facilitates ease, comfort, and cleanliness. Non-woven fabric’s outstanding qualities of absorbency, softness, durability, adaptability, and formulation compatibility guarantee that every wipe provides an unmatched level of hygienic and refreshing experience. As customers prioritize convenience and efficacy in their everyday routines, the wet wipes business will continue to see growth in the importance of non-woven fabric.

Essential Equipment and Supplies #3: Solution Preparation System

The production of moisturizing and revitalizing wet wipes involves a carefully blended solution that provides cleanliness, hydration, and effectiveness. The solution preparation system is a key component of this process, which mixes, blends, and dispenses the exact mixture of materials required to fully saturate each wipe. Let’s take a closer look at the complex inner workings of this crucial step in wet wipes manufacturing:

- Precision Blending and Mixing: The solution preparation system is equipped with advanced blending and mixing components that ensure the consistency of the solution and complete dispersion of the ingredients. The system carefully blends water, surfactants, preservatives, perfumes, and other active agents in the right amounts to create the desired formulation. Cutting-edge stirrers, emulsifiers, and homogenizers guarantee consistency and homogeneity by preventing particle separation or clumping.

- Automated Control and Monitoring: The automated control and monitoring features of the solution preparation system are crucial because they allow for precise mixing process control and real-time monitoring of vital parameters such as temperature, pH, viscosity, and concentration. Modern sensors and feedback systems reduce variability and ensure batch-to-batch consistency by verifying that the solution meets predetermined parameters. Operators can adjust settings and parameters as required to fine-tune the composition for maximum performance and effectiveness.

- Flexibility and Customisation: The solution preparation system’s unmatched flexibility and customization options allow manufacturers to customize formulas to meet specific needs and preferences. The system can handle a wide range of formulations with different concentrations, viscosities, and functions, whether it is producing delicate baby wipes, strong cleaning wipes, or luxurious beauty wipes. Its modular design and replaceable components enable swift and easy adaptation to changing production demands, ensuring agility and responsiveness to shifting market demands.

- Hygienic Handling and Storage: Maintaining strict hygiene standards is crucial when handling liquid formulations that are prone to contamination during wet wipes production. The solution preparation system is built using hygienic materials, smooth surfaces, and closed-loop technologies to reduce the risk of microbiological contamination. Automated cleaning and sterilization processes protect the finished product against microbiological development and spoiling, ensuring the integrity and purity of the solution.

- Scalability and Efficiency: The solution preparation system delivers scalability and efficiency to meet various production needs, whether producing small batches for niche markets or large-scale quantities for mass distribution. High-capacity tanks, pumps, and pipes enable continuous operation and fast throughput, saving downtime and increasing production. Integrated process controls and optimization algorithms minimize waste and energy use while maximizing resource utilization.

In summary, the solution preparation system is a crucial element of the wet wipes manufacturing process, enabling producers to create solutions that are effective, hygienic, and clean. The technology’s precise mixing and blending capabilities, automated control and monitoring features, flexibility and customization options, hygienic handling and storage protocols, and scalability and efficiency improvements enable manufacturers to create the perfect blend for each wet wipe application. The solution preparation system remains essential for offering wet wipes that exceed expectations in terms of performance, convenience, and customer satisfaction as expectations continue to evolve and expand.

Essential Equipment and Supplies #4: Packaging Machinery

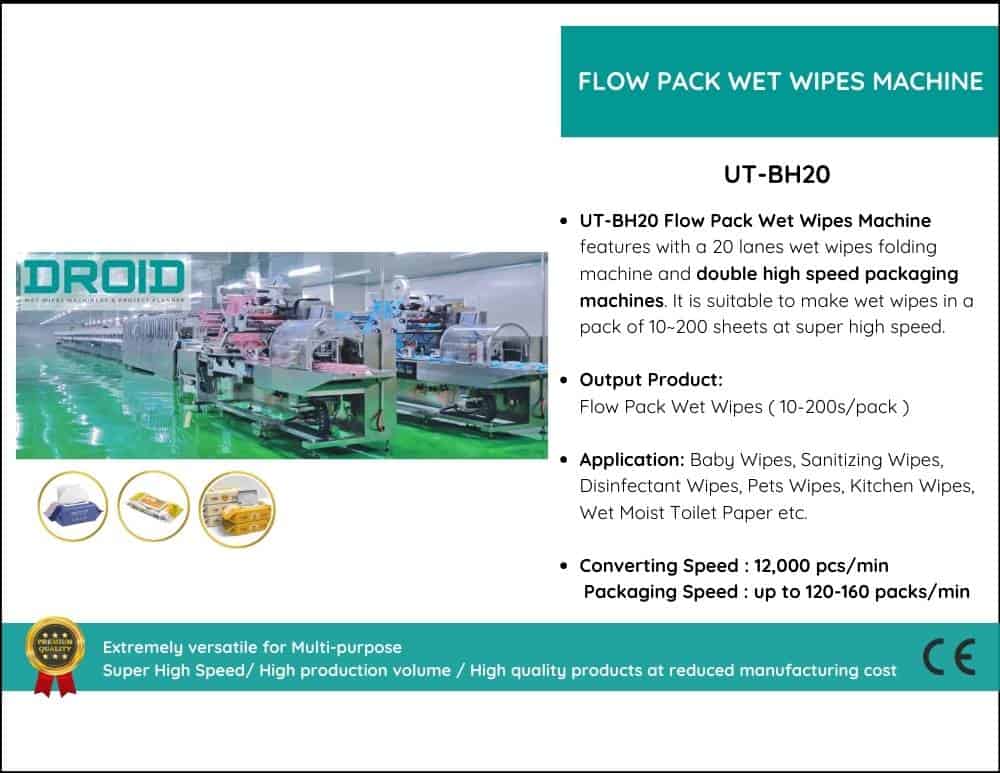

In the manufacturing process of wet wipes, the packaging equipment plays a crucial role in ensuring that each wipe is packed and labeled neatly, sealed securely, and shipped effectively. The packaging machinery comes at the end of the production process and is essential for maintaining the efficacy, freshness, and integrity of wet wipes while also enhancing their marketability. Let’s take a closer look at the various functions carried out by packing equipment in the wet wipes industry:

- Sealing Machines: The cutting-edge of packaging machinery includes sealing machines, which seal each package of wet wipes with great care to prevent leaks, contamination, and drying out. These machines use various sealing techniques, such as pressure, heat, and ultrasonic sealing, to create an airtight barrier that keeps moisture inside and preserves the wipes’ effectiveness. Advanced sealing technologies ensure constant seal quality and integrity, even when dealing with different packaging materials and dimensions.

- Labelling Machines: Wet wipes packaging is more than just a practical necessity; it also serves as a platform for branding, distinction, and communication. This is where labeling machines come in, as they label each package of wet wipes with information about the product, branding components, use guidelines and regulatory compliance markers. By using eye-catching images, captivating photography, or educational text, labeling machines ensure that each package stands out on the store shelf and effectively conveys its special selling point to customers.

- Cartoning Machines: These efficient devices allow producers of wet wipes in large quantities or multi-pack arrangements to assemble and package many packets into boxes or cartons quickly. Cartoning machines automate the folding, filling, and sealing of cartons, providing effective wet wipe packing and presentation for retail distribution. These machines support a wide range of packaging shapes with precision and dependability, whether it’s a display box for single packets or a larger carton for family-sized packs.

- Secondary Packaging Equipment: In addition to main packaging equipment, wet wipes require secondary packaging equipment to prepare them for transportation, storage, and exhibition. Secondary packaging includes shrink-wrapping, case packing, palletizer, and stretch wrapping equipment, which makes it easier to bundle, stack, and palletize packed wet wipes for handling and shipping. By streamlining secondary packing procedures, manufacturers can reduce transportation expenses, increase storage effectiveness, and ensure the safe and secure transportation of wet wipes from the manufacturing plant to the final destination.

- Integration of Quality Control: Packaging equipment is often equipped with integrated quality control capabilities, such as barcode scanners, weight checkers, and vision inspection systems, to ensure the integrity and compliance of packed wet wipes. These systems identify and reject faulty or non-compliant packets, ensuring that only superior goods are sent into the market. By integrating quality control procedures, packaging equipment manufacturers can protect their brand’s image, reduce product recalls, and increase customer satisfaction.

In summary, the packaging equipment is essential to the wet wipes manufacturing process, providing the last bit of perfection in terms of appearance, protection, and handling. It ensures that wet wipes not only meet but also surpass customer expectations for quality, convenience, and dependability with its sealing, labeling, cartoning, secondary packaging, and quality control capabilities. The packaging equipment plays a critical part in producing goods that appeal to customers and promote brand success as the wet wipes industry develops and grows.

Essential Equipment and Supplies #5: Quality Control Equipment

Quality control equipment is an essential part of the manufacturing process for wet wipes. It ensures that every wipe is dependable, performs as intended, and is safe for consumers. Quality control equipment can check for everything from the moisture content of the wipes to microbial contamination. Let’s take a closer look at the various types of quality control tools necessary for the manufacture of wet wipes:

- Moisture Analyzers: Moisture content is a critical aspect of wet wipes production, as it can impact the product’s effectiveness, shelf life, and user experience. Moisture analyzers are highly precise machines that measure the moisture levels in wet wipes. They help wet wipes manufacturers maintain formulation uniformity, avoid over-drying or under-drying, and ensure that every wipe has the right moisture content.

- Tensile Testers: Wet wipes must be strong and durable, especially when subjected to rigorous cleaning, wiping, and sanitizing. Tensile testers evaluate the elongation and tensile strength of wet wipes and measure their resistance to ripping, stretching, and deformation. By testing the wipes under-regulated tensile stresses, producers can improve customer satisfaction and durability by using the best materials, streamlining manufacturing processes, and designing better products.

- Microbial Testing Kits: Wet wipes are prone to microbial contamination, which can compromise their safety, effectiveness, and shelf life. Microbial testing kits detect and quantify microbial contamination in wet wipes, including bacteria, fungi, and viruses. By performing microbial testing at different stages of production, from raw materials to finished products, manufacturers can identify potential contamination risks and take preventive measures such as strict sanitation protocols and preservative formulations.

- Chemical Analysis Tools: Wet wipes contain various chemical compounds such as surfactants, preservatives, scents, and active agents. Each one needs to be carefully inspected to ensure product quality and safety. Chemical analysis tools such as mass spectrometers, spectrophotometers, and chromatographs help manufacturers to analyze and quantify the chemical ingredients in wet wipe compositions. Thorough chemical testing can confirm ingredient potency, purity, and stability, ensuring that every wipe complies with regulations and performs as intended.

- Visual Inspection Systems: Automated imaging technology is used to inspect wet wipes for flaws, anomalies, and discrepancies in appearance, texture, and packing. High-resolution cameras, image processing algorithms, and artificial intelligence capabilities enable manufacturers to detect rips, folds, discolorations, and misalignments in the wipes. By automating visual inspection operations, manufacturers can improve product quality, reduce waste, and optimize production workflows.

In conclusion, quality control equipment is essential for the manufacturing of wet wipes. It provides producers with the tools and innovations they need to ensure the highest levels of product dependability, safety, and quality. Tensile testers, moisture analyzers, microbiological testing kits, chemical analysis devices, and visual inspection systems enable manufacturers to detect, address, and avoid quality problems, ensuring that every wipe offers maximum performance and customer satisfaction. As the wet wipes market expands daily, quality control equipment remains crucial to protecting consumer health, establishing brand trust, and driving industry innovation.