Converting & Packaging

Our Solution

Automated Wet Wipes Production Line for Single Sachet Wet Wipes

Automated Wet Wipes Production Line for On-the-go Pocket Wipes (5~40s/pack)

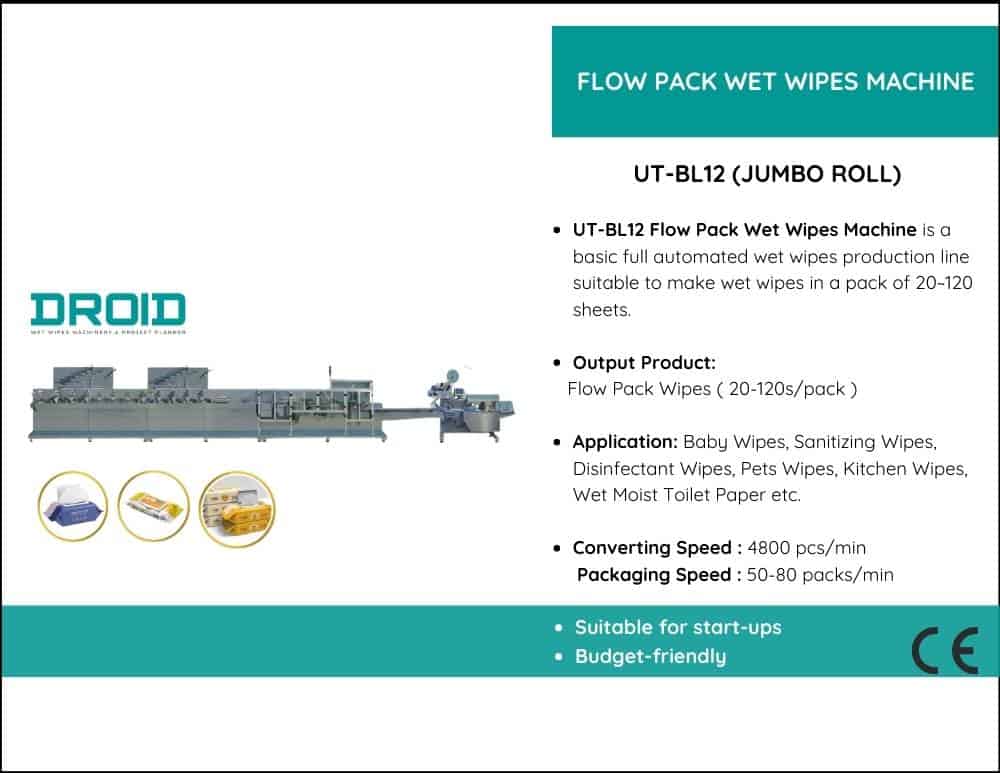

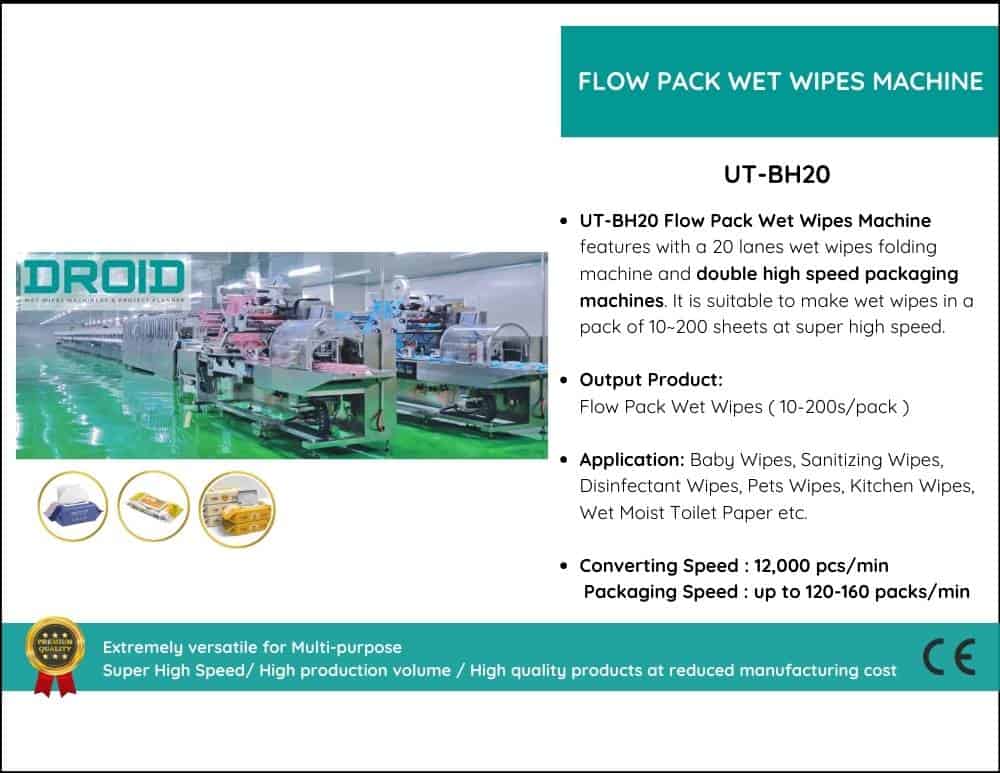

Automated Wet Wipes Production Line for Flow Pack Wet Wipes (10~200s/pack)

What is a converting machine?

A converting machine converts raw materials (such as paper, plastic films, or nonwovens) into finished goods like wipes, pouches, labels, and flexible packaging.

What is a packaging machine?

A packaging machine automates the process of enclosing and safeguarding items before distribution and sale. It may include bagging, boxing, sealing, shrink-wrapping, or palletizing.

What industries use converting and packaging machines?

Common industries encompass food and beverage, pharmaceuticals, cosmetics, hygiene products (such as wet wipes and tissues), pet care, automotive, and consumer goods.

What types of products can be made with converting machines?

Wet wipes, diapers, medical dressings, paper towels, sanitary pads, labels, pouches, and more are among the products.

What are the main types of converting machines?

- Slitter Rewinders

- Wet wipes converting machines

- Laminating machines

- Folding machines

- Die-cutting machines

What types of packaging machines are available?

- Horizontal & vertical form fill seal (HFFS/VFFS) machines

- Bagging machines

- Cartoning machines

- Wrapping machines

- Palletizing systems

What are the benefits of automating converting and packaging processes?

Automation speeds up production, increases uniformity, lowers labor costs, cuts waste, and improves the quality of the final product.

What factors should I consider when choosing a converting or packaging machine?

Consider material compatibility, machine speed (production capacity), flexibility (size and format changes), simplicity of use, maintenance needs, and total cost of ownership.

Can converting and packaging machines handle eco-friendly materials?

Yes, many current machines are intended to operate with biodegradable films, recyclable materials, and other environmentally friendly packaging solutions.

How important is machine customization for specific applications?

Customization is sometimes required, particularly in specialty businesses such as personal care or medical items. Customized machines offer maximum performance and adherence to industry rules.

How often do these machines require maintenance?

Preventive maintenance is usually planned monthly or quarterly, depending on consumption, and includes regular inspections for worn components, lubrication, and software upgrades.

Are converting and packaging machines compatible with Industry 4.0 / smart factory systems?

Yes, many current machines include IoT integration, data tracking, remote monitoring, and other Industry 4.0 capabilities.

What is the typical ROI for investing in automated converting and packaging equipment?

Based on manufacturing volume and labor savings, ROI may be realized in 1 to 3 years.

Do you provide operator training and technical support?

Yes, DROID can provide thorough operator training, installation, after-sales support, and replacement parts services.

Can I upgrade my existing line with new packaging equipment?

Absolutely. Many packaging machines are intended to work with current manufacturing lines, increasing productivity and efficiency.