A Buying Guide for Wet Wipes Lid Applicator (Capping Machine)

As you consider purchasing a wet wipes lid applicator (capping machine) to put lid on flow pack wet wipes pouch. You might take 5 minutes to read this buying guide so as to make better informed purchase decision.

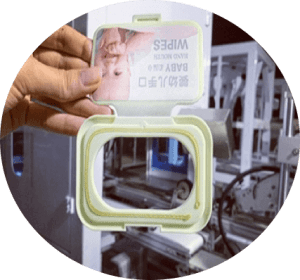

How to put plastic lid on wet wipes pouch?

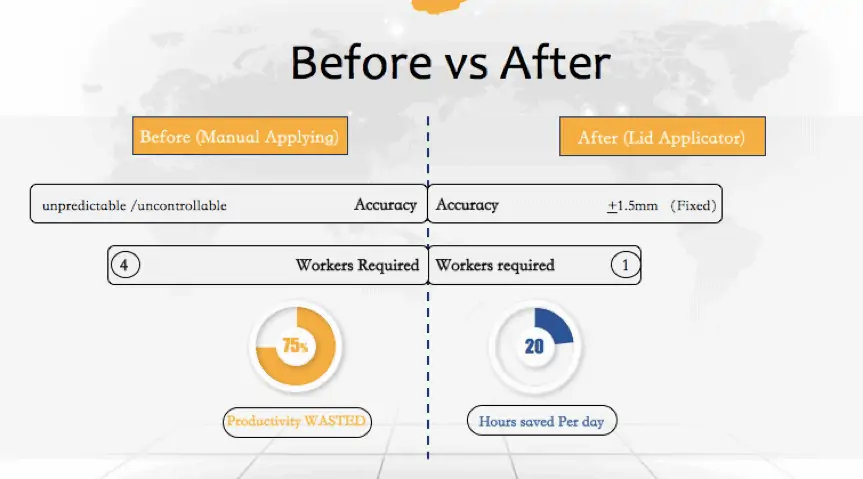

Manual V.s Automation

To apply lid cover on the wet wipes pouch, there are two systems:

Manual system with labor intervention V.s labor-free automation system.

Manual wet wipes lid application

Automated lid application by Robotic wet wipes capping machine

Choosing between the manual option and the automatic system is not that difficult. Both systems provide solutions for pick- and-place, while each has its unique features, advantages and downsides. By understanding these differences, and carefully evaluating your budget, labor costs, product quality standard and annual consumption, you can make the best decision.

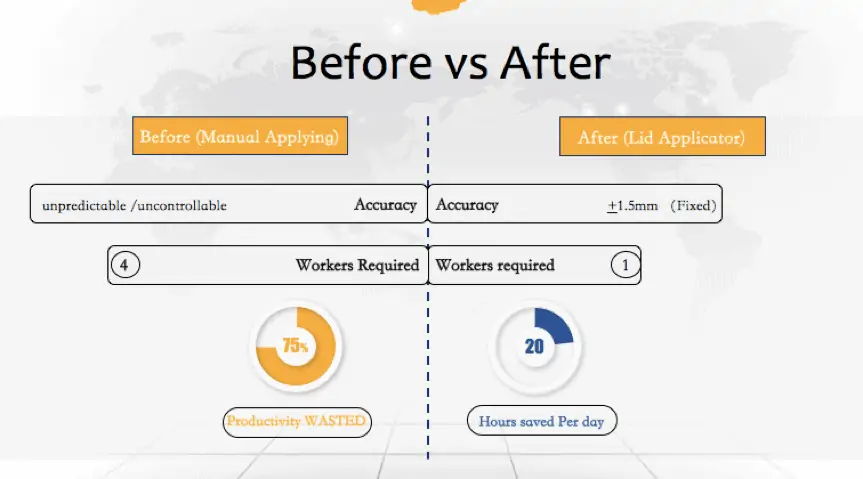

Labor cost

Traditional manual wet wipes lid application requires 3-4 labors sitting beside each production line to align with the capacity output at 2400~3600packs per hour. On the contrary, the automatic wet wipes lid applicator (capping machine) can be easily handled by one one labor for continuous operation up to 24 hours per day.

If you are in a market where labor costs are super unfriendly, and finding the cooperative labors is giving you much headache, you don’t need to struggle anymore. Automatic wet wipes lid applicator ( capping machine) is a more attractive option.

Quality of output product

We are talking about adherence to the specifications here.

In those terms, one can expect high level of adherence to the specification for each individual unit manufactured or each batch that is made under automatic wet wipes lid applicator.

Specifically speaking, Traditional Manual wet wipes Lid applying is Not a guarantee of product quality consistency and chances are high that you see the lid placed improperly or in a deviation <1-1.5mm under manual application.

As advanced and automation facilities are what Most international top-brand consumers are looking for in an OEM suppliers , automatic wet wipes lid applicator is the safer bet.

Manufacturing cost

In a highly competitive and price-sensitive market, Traditional Manual wet wipes Lid application is eroding your slim margin. The automation system, on the long run does help keep manufacturing costs down.

Statistic shows that the raw material (glue) costs up to $0.0028/pcs while the cost could be reduced to $0.0012/pcs only under automatic lid application. Though the price gap looks like a peanut but once it adds up to 50,0000 output, it is a stunning figure. Remember One cent you can save is another sent you can use to defeat your rival vendors.

Budget & ROI

For most of buyers, the purchase price of the wet wipes capping machine seems to be of their biggest concern. If you are looking for the smallest investment which falls within your tight budget frame, opting for a manual device seems to be the best move. Beside, you are able to get a passive ROI within 1 year and that is where the manual wet wipes capping system shines. On the contrary, one automated wet wipes lid applicator system might take you up to 2-3 years for return of investment.

Operational safety

Safety issue is often neglected by all.

The adhesive glue used to paste lid on wet wipes is a kind of Toxic &Volatile chemical substance, and the fact that manual system puts operators under exposure to this volatile substance makes the chances of Getting chronic lung disease slightly higher.

Are you going to pay the price ?

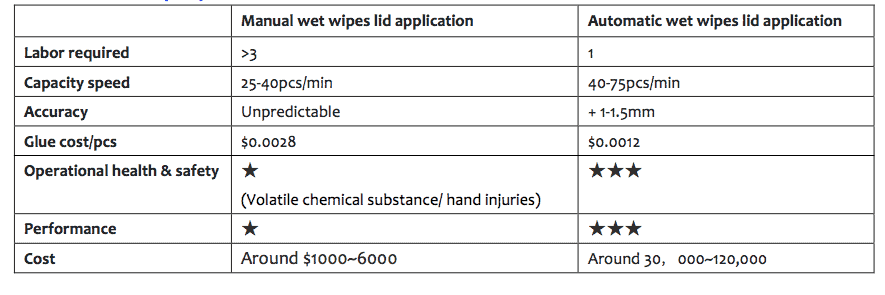

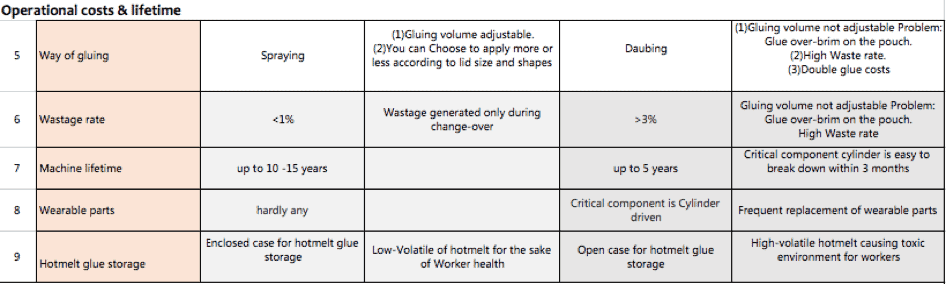

To sum up, here we have crafted this comparison sheet at a glance, together with the video illustration:

Supposing you have made your decision to set up a full automatic wet wipes lid applicator, does it mean you can stop head-scratching now ? Well, not at all.

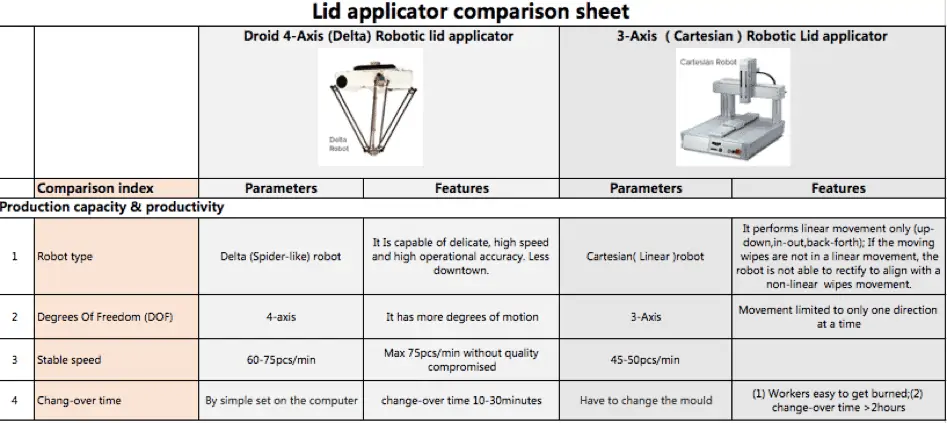

There are typically two types of automatic robots applied in wet wipes lid applicator the function of lid pick-and-place. Among so many vendors who have integrated the system in their own way, choosing the wrong one could even backfire.

4-Axis Spider robot vs 3-Aixs Cartesian (Linear) robot: Which one to choose?

The two most applicable robots in wet wipes lid pick-and-place application are 4-Axis Delta(Spider) Robot and 3-Axis Cartesian ( Linear) Robot (most commonly seen from Turkish machine suppliers.)

So in the integrated application for wet wipes capping machine , what is the key difference between them and which one is technically better?

4-Axis Delta robot

In general, 4-Axis Delta Robot Is capable of delicate, high speed and high operational accuracy. Less downtown.

3-Aixs Cartesian (Linear) robot

A cartesian coordinate robot (also called linear robot) is an industrial robot whose three principal axes of control are linear (i.e. they move in a straight line rather than rotate) and are at right angles to each other.

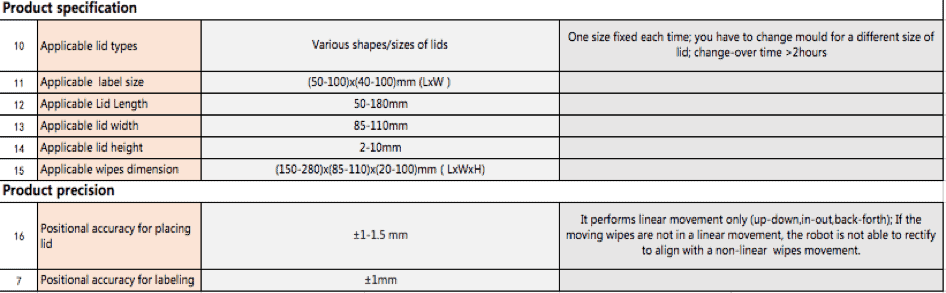

It performs linear movement only (up-down, in-out, back-forth); If the moving wipes are not in a linear movement, the robot is not able to rectify to align with a non-linear movement of wipes.

Picking between robot types

To pick a robot for wet wipes capping machine, first we need to evaluate the application’s needs.

That starts with operational accuracy and capacity speed.

Operational accuracy:

The degrees of Freedom (DOF) of each types of robot defines how precise their action could be. 4-Axis has more degrees of motion due to its spider-like structure, therefore it is easier that it moves in alignment with the moving wet wipes.

While the movement of a linear robot is limited to only one direction at a time, once the wipes are not moving in linear direction, it results in improper placing.

Linear robot wet wipes lid applicator performance

4 Axis Spider robot wet wipes lid applicator performance

Capacity Speed:

With gantry-style cartesian robots, of course, the traditional method is to move in cartesian coordinates. It’s a probably cheaper solution.But for high-speed pick and place applications, spider robot could be the best option.

Cartesian (Linear )robots are typically slower, Delta (Spider) robots excel at conveyor-tracking tasks, typically using vision systems to pick and place parts.

Besides, the spider robot has a very high mechanical advantage in performance and flexibility when compared to cartesian robots.

[Performance review]

Droid DH-L300 4-Axis Spider robotic wet wipes lid applicator

Model: DH-L300

- Application: Automatically applying Lid on wet wipes pouch

- Robot arm: 4 Axle

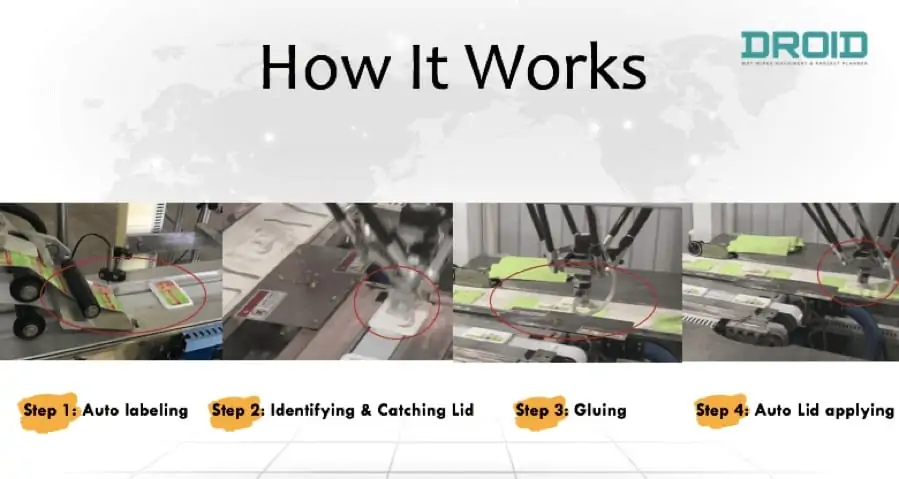

- Work flow: labeling- catching lid- glue spraying- identifying -lid applying

- Capacity: 60~75 pcs/min (Single sucker)

- Control system:PLC + Full servo driven system

- Operation system:Panasonic control system

- Applicable label size range: Length: 50-100mm; Width 40-100mm.

- Applicable: wet wipes size: Length: 50-180mm, Width: 80-110mm, Height: 20-100mm.

- Multi-dimensional lid magazine

- Applicable lid types: multiple types/sizes

- Lid thickness:5~10mm; Width:20~100mm; Length:20~150mm

- Positional deviation: within ±1-1.5mm

- Wastage:<1%

- Cover storage:2 sets of auto lid delivery stand for Max 360pcs storage.

- Power: DC24V; 380v/50Hz | 8kw

- Operation interface: 19 inch display of Human-computer

- Machine size: 3800*1500*2100mm (L*W*H)

- Machine weight: 1500kg

Click here to check DH-L300 Spider Robot Wet Wipes Lid Applicator running video

Comparison sheet on Droid DH-L300 spider robot wet wipes lid applicator and Cartesian (Linear) Robotic wet wipes lid applicator.

If you are looking for a high performance robotic wet wipes lid applicator machine, please send your inquiry here.

Our sales specialist will get in touch with you in 24 hours.

Model: DH-L300

Model: DH-L300

Leave a Reply

Want to join the discussion?Feel free to contribute!